Electric heating floor and paving method thereof

An electric heating floor and floor technology, applied in the field of building decoration materials, can solve the problems of difficult heat transfer quickly, short heat conduction path, low heat conduction efficiency, etc., and achieve the effect of short heat conduction path, not easy to crack, and high heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

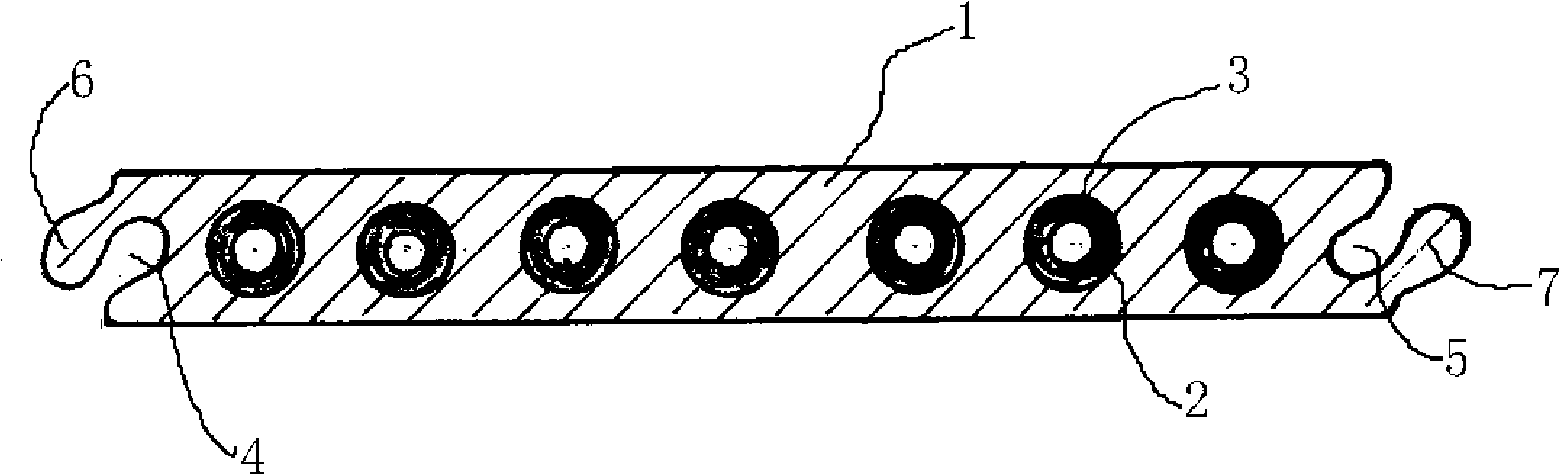

[0024] Embodiment 1: as figure 1 As shown, the interior of the floor body 1 is provided with seven through holes 2 that pass through the two ends of the floor body. The electric heating element 3, the outer surface of the electric heating element 3 is in contact with the inner wall of the through hole 2, the electric heating element 3 has a circular hollow tubular structure, the through hole 2 has a corresponding circular structure, and the electric heating element 3 between the seven through holes 2 in parallel with each other. The opposite sides of the floor body are centrally symmetrical, and the first side of the floor body forms a first slot 4 extending along the first side of the floor body and having a cross-section such that the inner end is larger and the outer end is smaller. The second side of the opposite floor body forms a second slot 5 that extends along the second side of the floor body and has a large inner end and a small outer end in cross section. The upper...

Embodiment 2

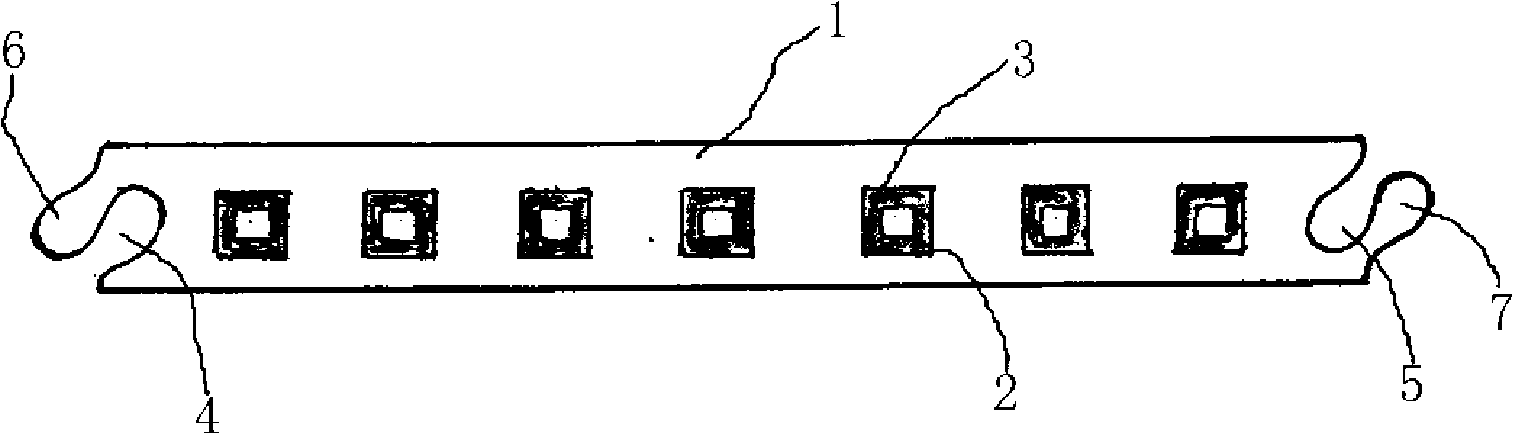

[0026] Embodiment 2: as figure 2 As shown, the interior of the floor body 1 is provided with seven through holes 2 that pass through the two ends of the floor body. The electric heating element 3, the outer surface of the electric heating element 3 is in contact with the inner wall of the through hole 2, the electric heating element 3 has a square hollow tubular structure, the through hole 2 has a corresponding square structure, and the electric heating elements 3 of the seven through holes 2 are connected in series . The opposite sides of the floor body are centrally symmetrical, and the first side of the floor body forms a first slot 4 extending along the first side of the floor body and having a cross-section such that the inner end is larger and the outer end is smaller. The second side of the opposite floor body forms a second slot 5 that extends along the second side of the floor body and has a large inner end and a small outer end in cross section. The upper wall of t...

Embodiment 3

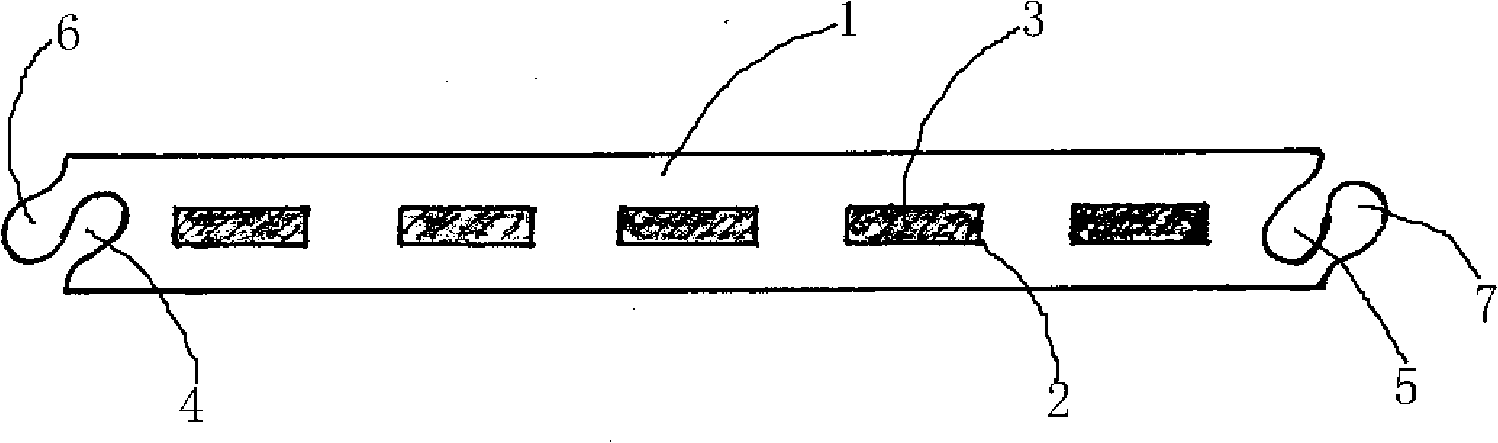

[0028] Embodiment 3: as image 3 As shown, the interior of the floor body 1 is provided with seven through holes 2 that pass through the two ends of the floor body. The electric heating element 3, the outer surface of the electric heating element 3 is in contact with the inner wall of the through hole 2, the cross section of the electric heating element 3 has a solid plate structure, the through hole 2 of the floor body 1 has a corresponding rectangular structure, and the electric heating elements of the five through holes 2 The elements 3 are connected in parallel with each other. The opposite sides of the floor body are symmetrical to the center, and the first side of the floor body forms a first slot 4 extending along the first side of the floor body and having a cross-section such that the inner end is larger and the outer end is smaller, opposite to the first side The second side of the floor body forms a second slot 5 extending along the second side of the floor body an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com