A dual-row power tube electric vehicle controller

A technology of electric vehicle controller and power tube, applied in the direction of sealing shell, cooling/ventilation/heating transformation, etc., can solve the problems of power tube burnout failure, power burnout failure, short circuit inside the shell, etc., to ensure timely Effectiveness and effectiveness, avoid excessive heat concentration, good sealing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

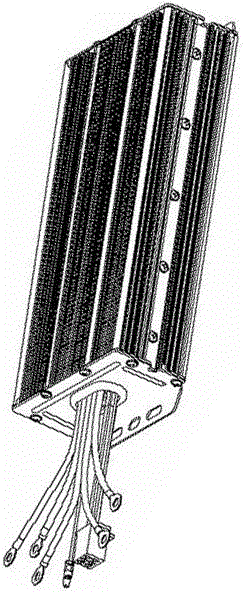

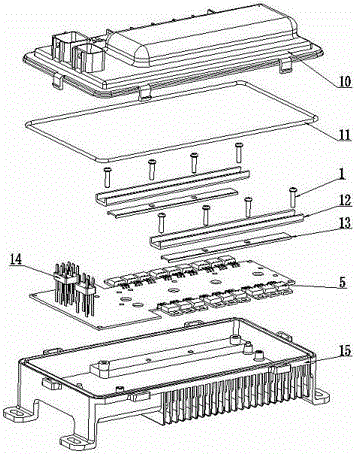

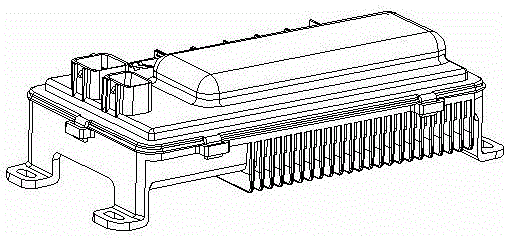

[0012] Such as image 3 , Figure 4 Shown: the present invention comprises plastic cover 10, sealing strip 11, screw 1, pressure plate 12, rubber strip 13, eighteen power tubes 5 welded on the circuit board, two groups of functional plugs 14 welded on the circuit board, Cast aluminum cooling case 15. The controller is a double-row power tube 5 electric vehicle controller with an upper and lower structure. The upper part is a plastic cover 10, and the lower part is a cast aluminum heat dissipation shell 15. There is a sealing strip 11 between the plastic cover 10 and the cast aluminum heat dissipation shell 15, and the inside contains There are eighteen power tubes 5 and two sets of functional plugs 14 welded on the circuit board. The screws 1 pass through the pressure plate 12 and the rubber strip 13 and are assembled on the cast aluminum heat sink 15. There is a place on the upper edge of the cast aluminum heat sink 15 The groove of the sealing strip 11 has strip-shaped hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com