Suction disc

A technology of suction cups and suction parts, which is applied to suction cups, connecting components, mechanical equipment, etc., can solve the problems of increased manufacturing costs, easily damaged suction cup parts, and many processes, and achieves long service life, low processing cost, and smooth curtain surface. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

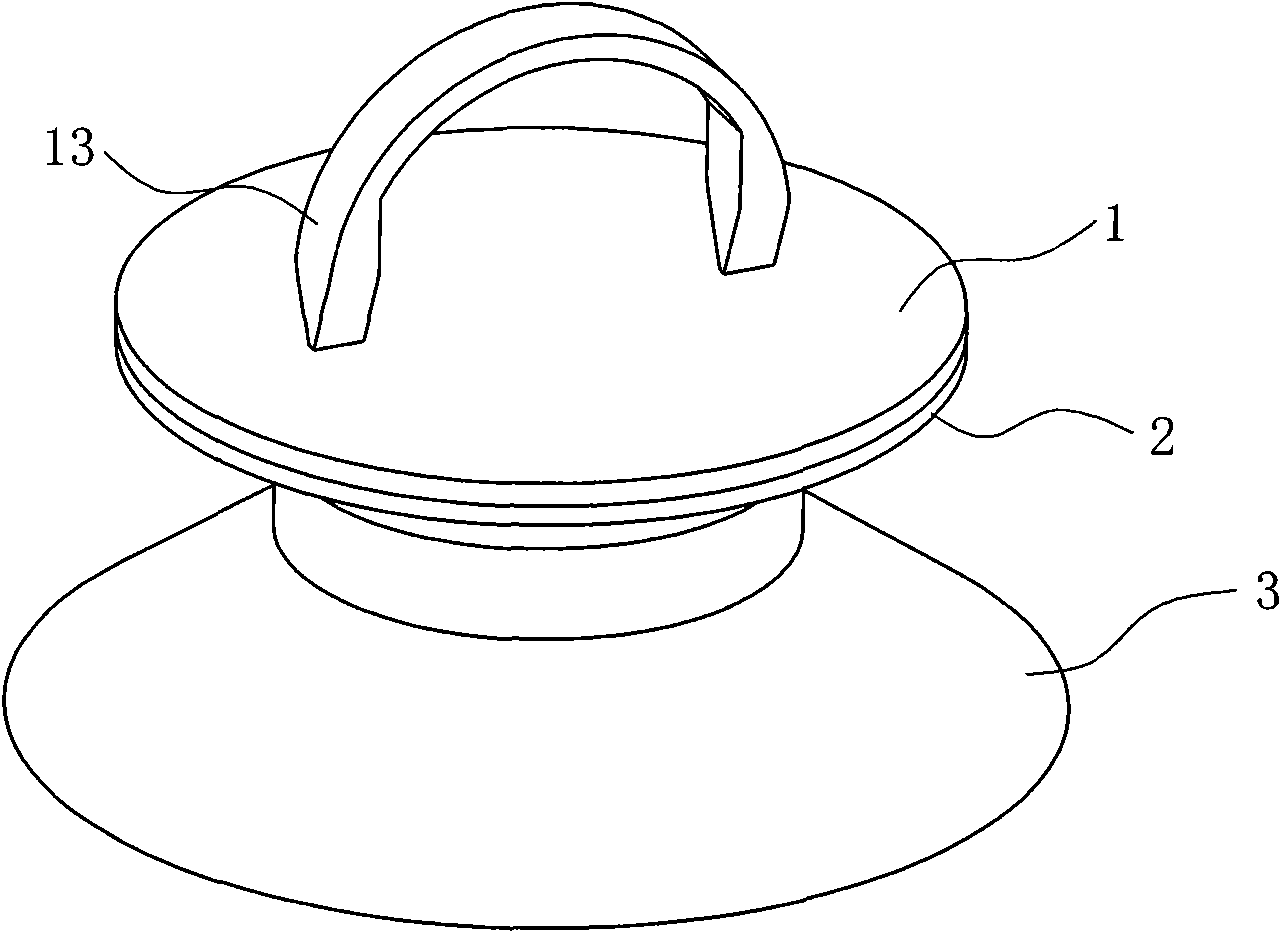

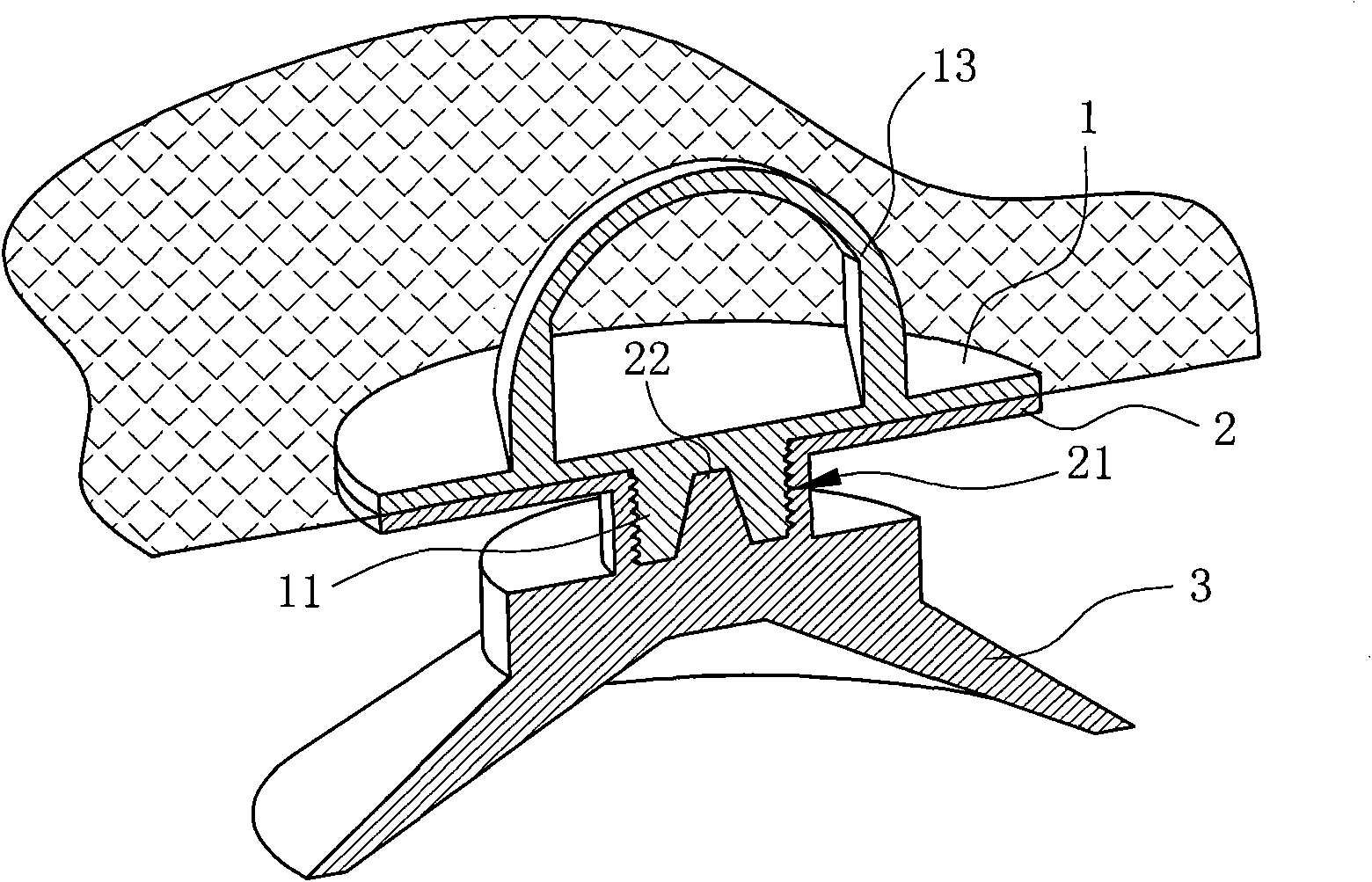

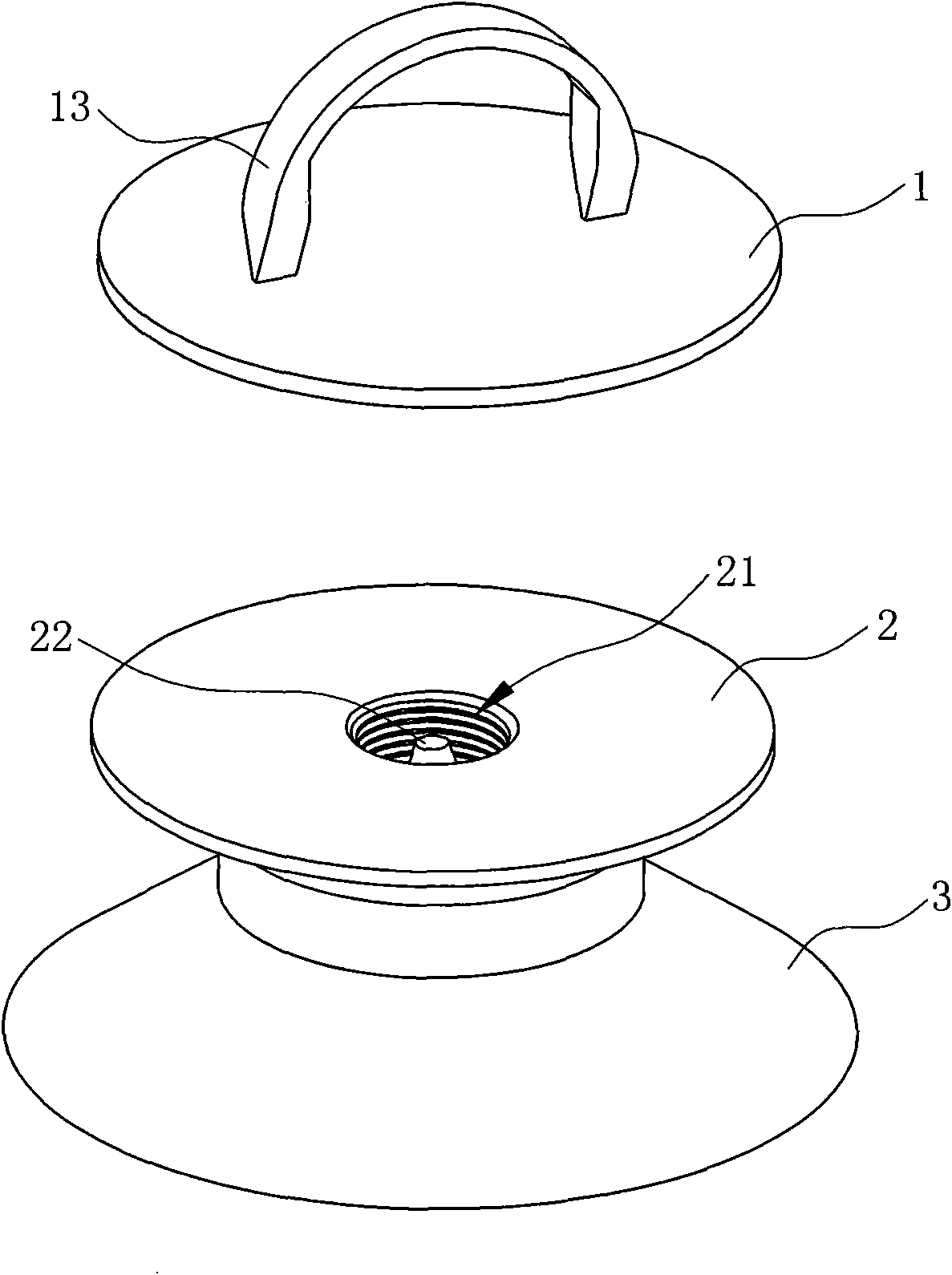

[0026] Such as Figure 1 ~ Figure 4 As shown, the suction cup includes a suction part 3 and a first support surface 1 and a second support surface 2 arranged on the suction part 3 in sequence from top to bottom;

[0027] Wherein, the suction part 3 is similar to the suction part on a common sucker, and can be adsorbed on a smooth surface. The suction part 3 and the second support surface 2 are integrally manufactured, and the surface of the first support surface 1 is provided with a pull ring 13 ;

[0028] The first supporting surface 1 and the second supporting surface 2 are detachably connected together through threaded connection, specifically: an outwardly protruding threaded connecting column 11 is provided at the center of the bottom of the first supporting surface 1, and the The surface of the second support surface 2 is correspondingly provided with a screw hole 21, and the threaded connection column 11 can be screwed into the screw hole 21 to realize the movable sepa...

Embodiment 2

[0032] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: the surface of the first support surface 1 is provided with a "one"-shaped fastening groove 14. 1 screwed onto the second support surface 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com