Target fiber grating rheometer

A fiber grating and flow meter technology, applied in the direction of fluid velocity measurement, velocity/acceleration/impact measurement, instruments, etc., can solve the problems of high cost, low precision, poor waterproof performance, etc., achieve good waterproof performance, improve measurement accuracy, To achieve the effect of temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

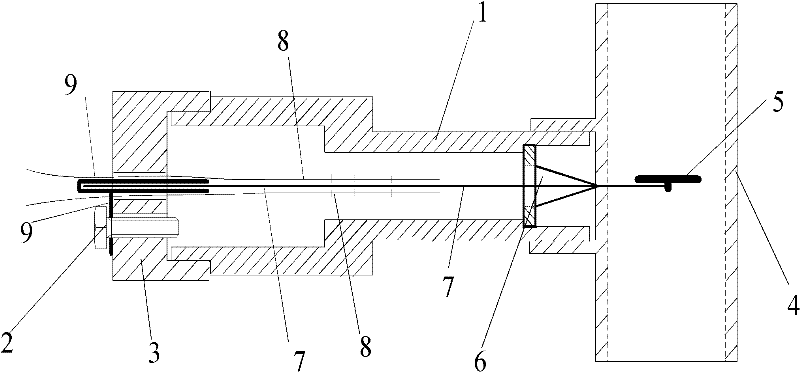

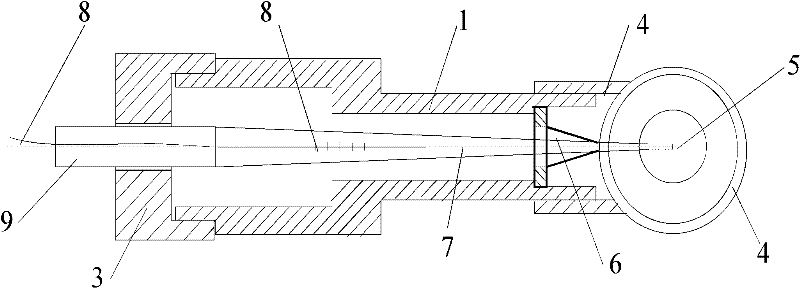

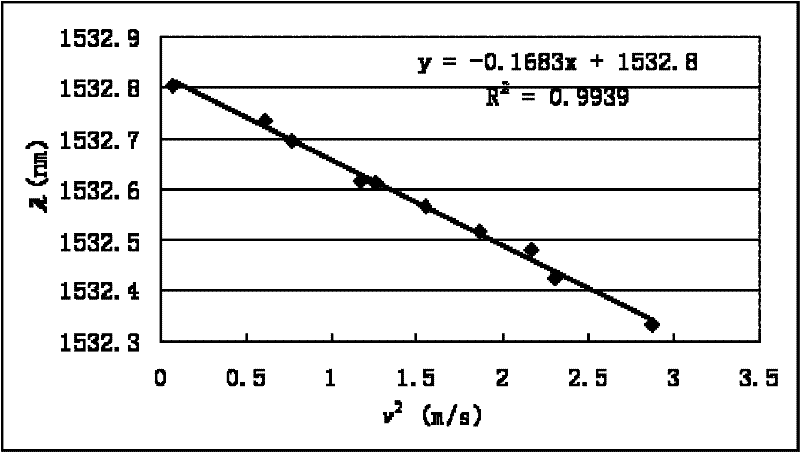

[0023] figure 1 , figure 2 Among them, one end of the housing 1 is connected to a detachable tee 4 with a variable inner diameter, and the other end of the housing 1 is provided with an end cover 3 with a cross-shaped hole and a screw hole, and a fixed metal sheet 9 is arranged in the cross-shaped hole, and the fixed metal A cantilever beam 7 of equal strength is connected to the sheet 9 . The measurement grating 8 of the double fiber grating is evenly pasted on both sides of the cantilever beam 7 by adhesive, and the other end of the cantilever beam 7 is directly fixedly connected with the circular metal target piece 5, and the metal target piece 5 is placed in the tee 4, and the feeling The force corresponding to the flow velocity is transmitted to the cantilever beam 7 with equal strength. The cantilever beam 7 is covered with a tapered soft rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com