Fiber grating temperature sensor for electrolytic bath shell

A temperature sensor, fiber grating technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as unfavorable data storage and analysis, large workload, and large temperature measurement errors, and achieve quasi-distributed Real-time monitoring, improving life and stability, anti-electromagnetic interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and example.

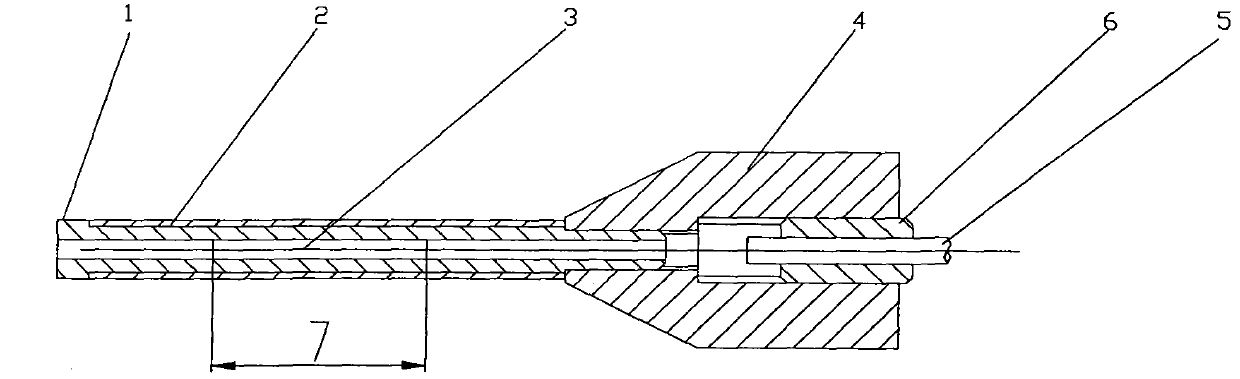

[0023] figure 1 It is a structural schematic diagram of the present invention, and the composition of the fiber grating temperature sensor of the electrolytic cell shell of the present invention is as follows: the optical fiber support 1 and the sleeve pipe 2 are installed in a gap, and the cooling head 4 is threadedly connected with the optical fiber support 1, so that the left end of the optical fiber support 1 is connected to the cooling head. 4Clamp sleeve 2. The sheath of the armored optical cable 5 is bonded to the hollow screw 6 (high-temperature glue), and through the connection between the hollow screw 6 and the cooling head 4, a hollow column with a diameter of 0.5 mm is provided in the center of the fiber support 1 to ensure that the fiber grating 3 is in the axial direction of the fiber support 1. Location.

[0024] The specific manufacturing proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com