Fixing device and image forming device

An image and fixing part technology, applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc. and other problems, to achieve the effects of deformation suppression, high fixing processing, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be described below with reference to the drawings.

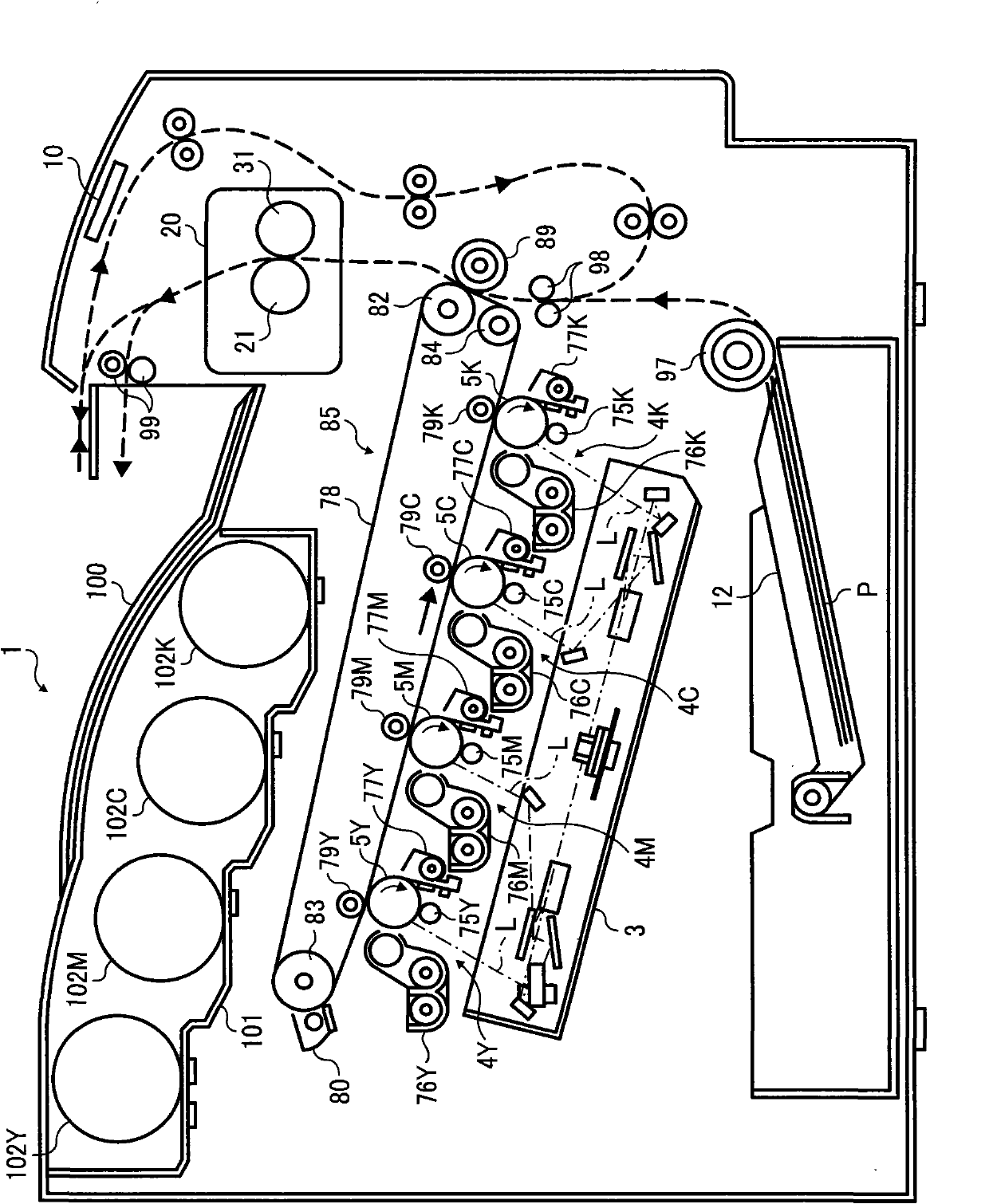

[0063] figure 1 Shown is a schematic configuration diagram illustrating the entire image forming apparatus according to the embodiment of the present invention. In this example, a tandem color printer is displayed as the image forming apparatus.

[0064] figure 1 In the tank accommodating portion 101 provided above the main body 1 of the image forming apparatus, four toner tanks 102Y, 102M, 102C, 102C, 102K.

[0065] Below the tank accommodating portion 101, an intermediate transfer unit 85 is arranged. The four image forming sections 4Y, 4M, 4C, and 4K corresponding to the respective colors (yellow, magenta, cyan, and black) face the intermediate transfer belt 78 provided in the intermediate transfer unit 85 .

[0066] Photoreceptor drums 5Y, 5M, 5C, and 5K are arranged in the image forming units 4Y, 4M, 4C, and 4K, respectively. In addition, around the respective pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com