Belt cleaning apparatus and image forming apparatus

一种清洁装置、清洁刮板的技术,应用在应用电荷图形的电记录工艺、应用电荷图形的电记录工艺的设备、仪器等方向,能够解决除去残留调色剂、残留调色剂除去效率降低、不能得到中间转印带的外周面清洁性能等问题,达到提高除去效率、均匀清洁性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

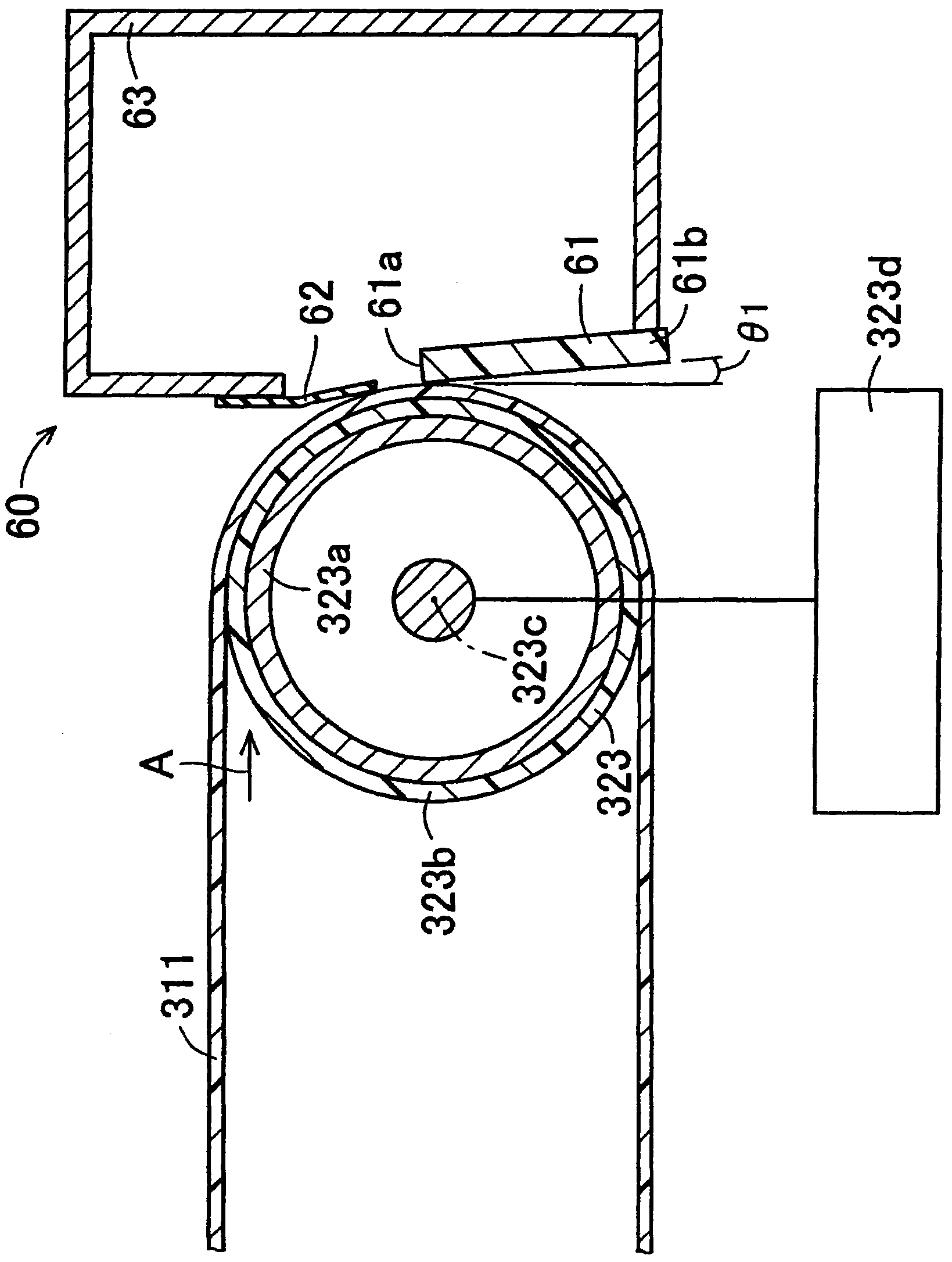

[0092] The intermediate transfer belt and the cleaning blade are constituted as follows.

[0093] [Intermediate transfer belt]

[0094] The intermediate transfer belt was formed such that an elastic layer made of urethane rubber with a width of 337 mm and a thickness of 150 μm was formed at the center in the width direction of the surface of a substrate made of polyimide with a width of 357 mm. In addition, the intermediate transfer belt was rotated and conveyed at a rotational peripheral speed of 220 mm / sec, and the meandering width was in the range of 0.5 to 3 mm.

[0095] [Cleaning scraper]

[0096] As a cleaning blade, a width of 340 mm in the long side direction, a width of 9.0 mm in the short side direction, a thickness of 2.0 mm, and a Young's modulus of 8.53 MPa (870 gf / mm 2 ) scraper made of polyurethane rubber. In addition, one end in the short-side direction of the cleaning blade is arranged so as to be in contact with a region of the outer peripheral surface of ...

Embodiment 2

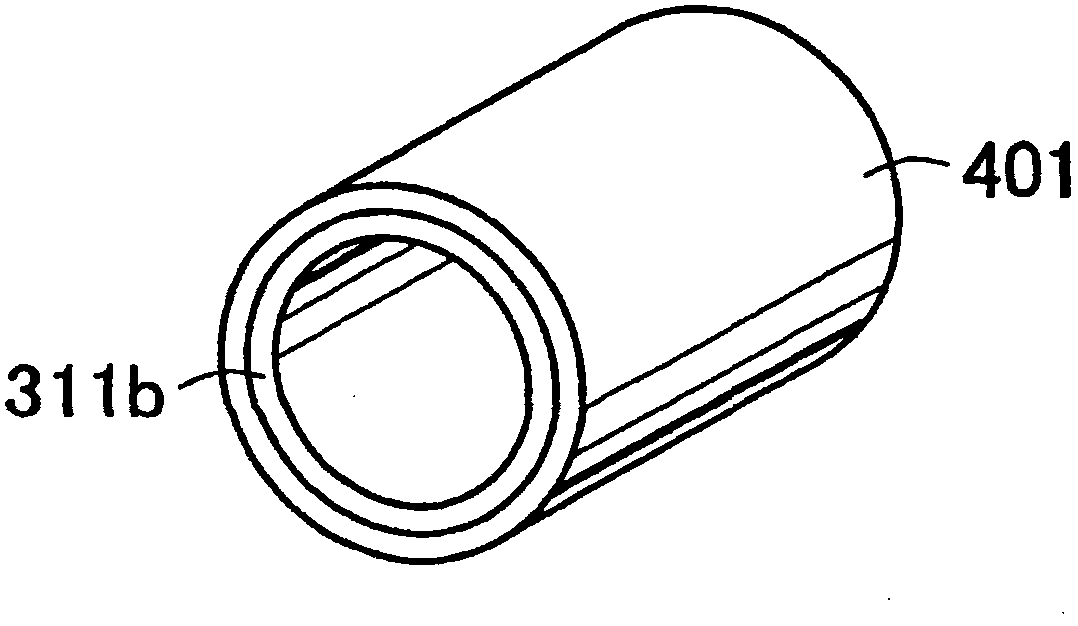

[0098] [Intermediate transfer belt]

[0099] The structure was the same as that of the intermediate transfer belt of Example 1 except that the thickness of the elastic layer was 250 μm.

[0100] [Cleaning scraper]

[0101] It was comprised similarly to the cleaning blade of Example 1 except that the width in the longitudinal direction was 341 mm.

Embodiment 3

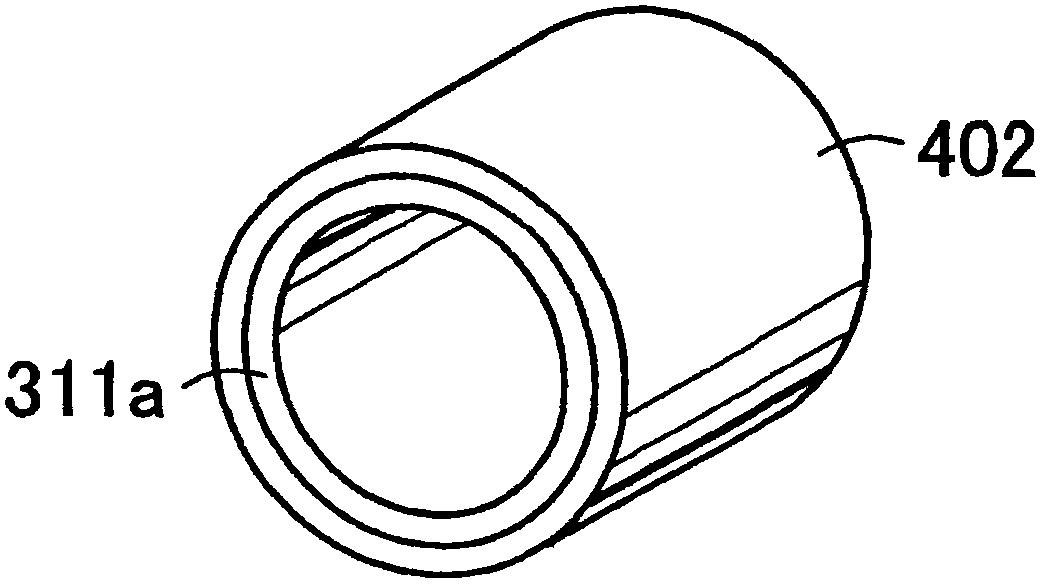

[0103] [Intermediate transfer belt]

[0104] The structure was the same as that of the intermediate transfer belt of Example 1 except that the thickness of the elastic layer was 400 μm.

[0105] [Cleaning scraper]

[0106] It was comprised similarly to the cleaning blade of Example 1 except that the width in the longitudinal direction was 342 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com