Novel catalyst for dioxin degradation and preparation method thereof

A catalyst and catalyst carrier technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., to achieve the effect of small particle size, simple preparation method, and rich surface acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

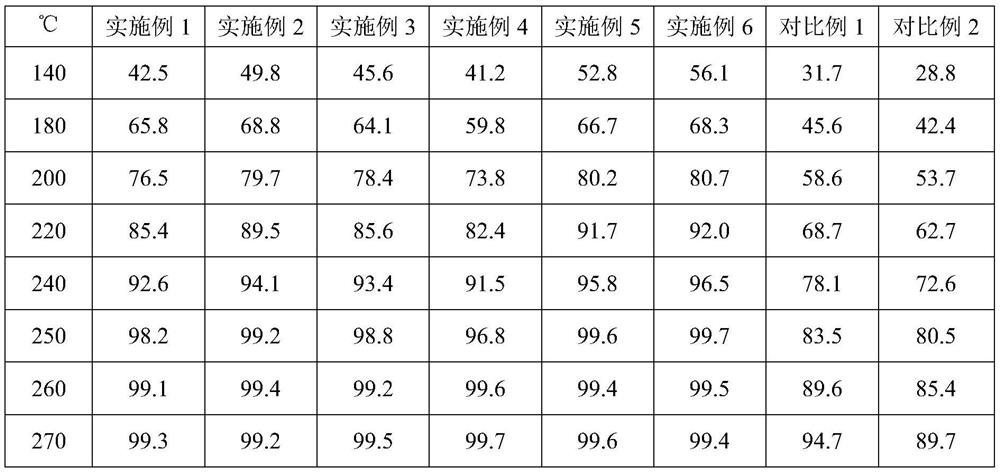

Examples

Embodiment 1

[0024] (1) at first 6.1g ammonium metavanadate is dissolved in 150mL concentration and is 13% in the oxalic acid solution, stirs to make it dissolve completely;

[0025] (2) Add 4.0g of ammonium paratungstate to the above oxalic acid solution, then fully stir at 40°C to dissolve it;

[0026] (3) Continue to add 1.2 g of ferric sulfate in the above oxalic acid solution, fully stir to dissolve it at 40°C;

[0027] (4) In the oxalic acid solution containing vanadium, tungsten and iron precursors, add 79g TiO 2 and 10g SiO 2 , keep the above temperature and continue to stir for 5 hours to carry out the aging of the catalyst;

[0028] (5) After the aging is completed, the TiO loaded with the active component precursor 2 and SiO 2 The mixture was dried in a blast drying oven for 12 hours at a drying temperature of 80°C;

[0029] (6) The dried catalyst precursor was calcined in a muffle furnace at 400° C. for 5 hours. After the calcination, a dioxin-degraded catalyst was obtaine...

Embodiment 2

[0031] (1) First, 8.5 g of vanadyl oxalate was dissolved in 120 mL of 18% oxalic acid solution, and stirred to completely dissolve it;

[0032] (2) Add 5.0g of ammonium metatungstate to the above oxalic acid solution, then fully stir at 60°C to dissolve it;

[0033] (3) Continue to add 3.5 g of ferric sulfate in the above oxalic acid solution, fully stir it to dissolve it at 60° C.;

[0034] (4) In the oxalic acid solution containing vanadium, tungsten and iron precursors, add 65g TiO 2 and 18.5g SiO 2 , keep the above temperature and continue to stir for 7 hours to carry out the aging of the catalyst;

[0035] (5) After the aging is completed, the TiO loaded with the active component precursor 2 and SiO 2 The mixture was dried in a blast drying oven for 20 hours at a drying temperature of 100°C;

[0036] (6) The dried catalyst precursor was calcined in a muffle furnace at 500° C. for 8 hours. After the calcination, a dioxin-degraded catalyst was obtained. The test result...

Embodiment 3

[0038] (1) at first 4.3g vanadyl sulfate is dissolved in 140mL concentration and is 20% oxalic acid solution, stirs to make it dissolve completely;

[0039] (2) Add 8.0g of ammonium metatungstate to the above oxalic acid solution, then fully stir at 70°C to dissolve it;

[0040] (3) Continue to add 2.3 g of ferric nitrate to the above oxalic acid solution, and fully stir it at 70° C. to dissolve it;

[0041] (4) In the oxalic acid solution containing vanadium, tungsten and iron precursors, add 70g TiO 2 and 22g SiO 2 , keep the above temperature and continue to stir for 10 hours to carry out the aging of the catalyst;

[0042] (5) After the aging is completed, the TiO loaded with the active component precursor 2 and SiO 2 The mixture was dried in a blast drying oven for 15 hours at a drying temperature of 120°C;

[0043] (6) The dried catalyst precursor was calcined in a muffle furnace at 550° C. for 10 hours. After the calcination, a dioxin-degraded catalyst was obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com