Novel fluorescent lamp electrode and installation method thereof

A fluorescent lamp and electrode technology, which is applied in the manufacture of electrode components, circuits, discharge lamps, etc., can solve the problems of insignificant quality of fluorescent lamps, short lifespan of lamp blackheads, and few application manufacturers, so as to reduce blackening phenomenon and save energy. The effect is remarkable and the market capacity is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

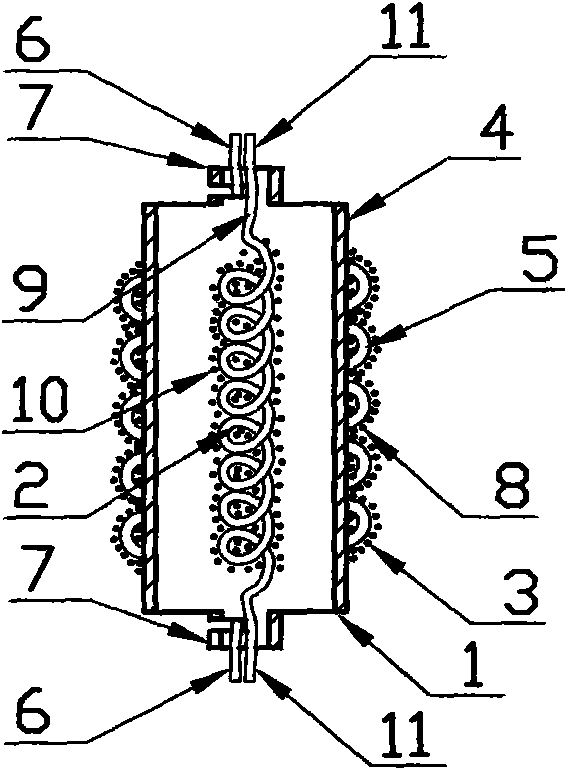

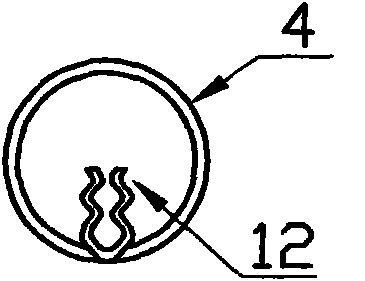

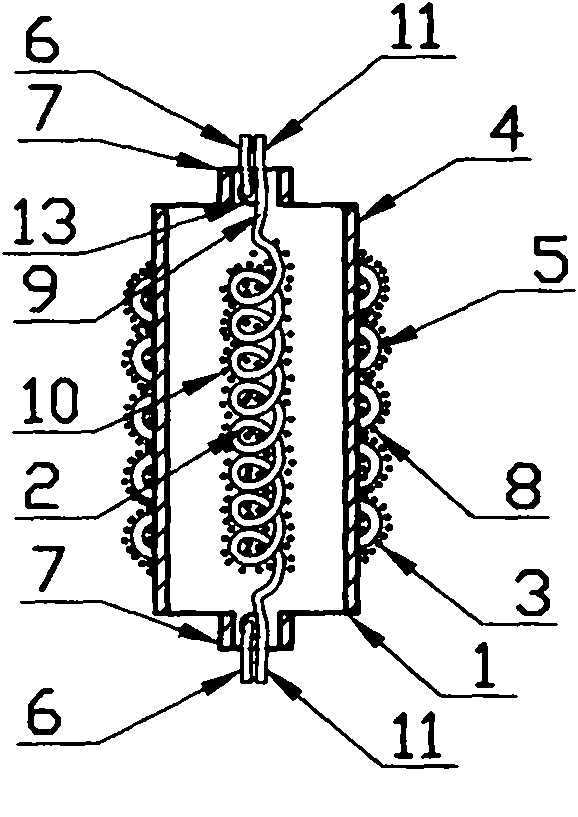

[0020] Such as figure 1 Shown is a schematic diagram of the structure of the new electrode of the present invention. The new electrode 1 of the fluorescent lamp is composed of a central electrode 2 and a screen electrode 3. The screen electrode 3 is processed into a hollow molybdenum tube 4 by using a molybdenum sheet, and a tungsten wire or a filament 5 is wound around the hollow molybdenum tube. 4, the lead wires 6 at both ends of the tungsten wire or filament 5 are respectively connected to the pins 7 at both ends of the hollow molybdenum tube, and the tungsten wire or filament 5 on the hollow molybdenum tube 4 is coated with cathode material 8 and sintered at high temperature; the central electrode 2 Composed of filament 9, the filament 9 coated with cathode material 10 is sintered at high temperature, placed in the inner hole of the hollow molybdenum tube 4 of the screen electrode 3, and the leads 11 at both ends are respectively connected to the pins 7 at both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com