Motor constant-speed forward/reverse rotation control circuit

A control circuit, forward and reverse technology, applied in excitation or armature current control, motor generator/starter, starter of a single DC motor, etc., can solve the problem of cumbersome control circuits, inoperable circuits, complicated circuits, etc. problems, to achieve the effect of low cost, few components and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

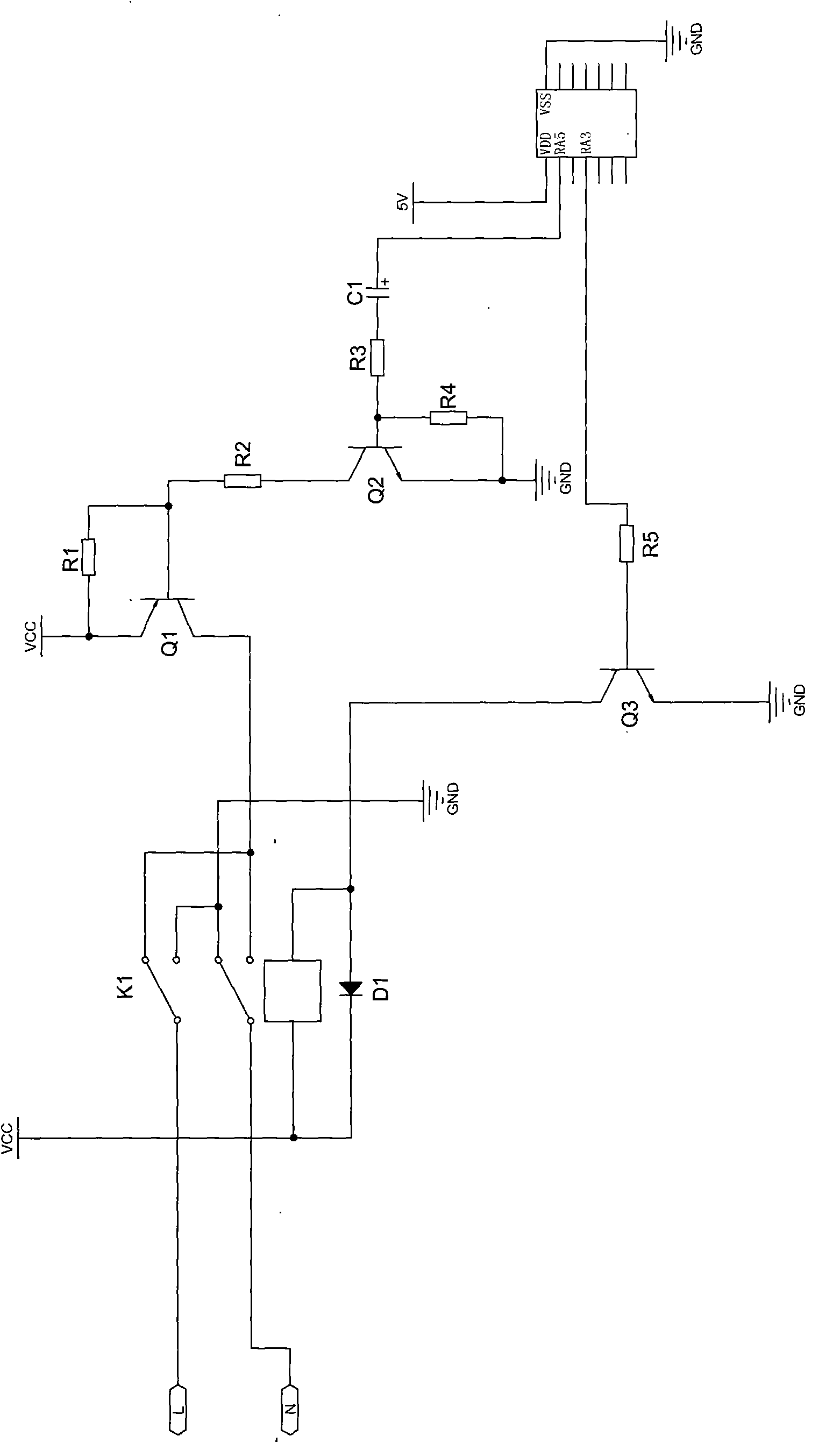

[0021] Embodiment: A constant speed forward and reverse control circuit for a motor, including a main chip U1, first, second and third transistors Q1, Q2, Q3 and an electromagnetic relay K1, the base of the third transistor Q3 passes through the fifth The resistor R5 is connected to the control signal output pin RA3 of the main chip U1, the control signal output pin RA3 outputs the forward and reverse control signals of the motor, the emitter of the third transistor Q3 is grounded to GND, and the third transistor Q3 The collector of Q3 is connected to the power supply VCC through the electromagnetic relay K1, and the electromagnetic relay K1 is provided with at least the first and second movable contacts corresponding to the motor positive pole L and the motor negative pole N; the electromagnetic relay K1 corresponds to the first movable contact The normally closed contact is connected to the collector of the first transistor Q1, and its corresponding normally open contact is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com