Device and method for preparing a sterile liquid for a filling plant

A technology for sterilizing liquids and filling systems, which is applied in chemical instruments and methods, liquid treatment, cleaning of filling devices, etc., and can solve problems such as damaged pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, it is assumed that the sterilizing liquid is sterilized water (sterilized water). However, other sterile liquids are also possible.

[0039] The following examples describe chemically sterile water (sterile-water) prepared with sterilizing agents. The sterilant may be a sterilant produced using electrochemical activation or a traditional chemical sterilant.

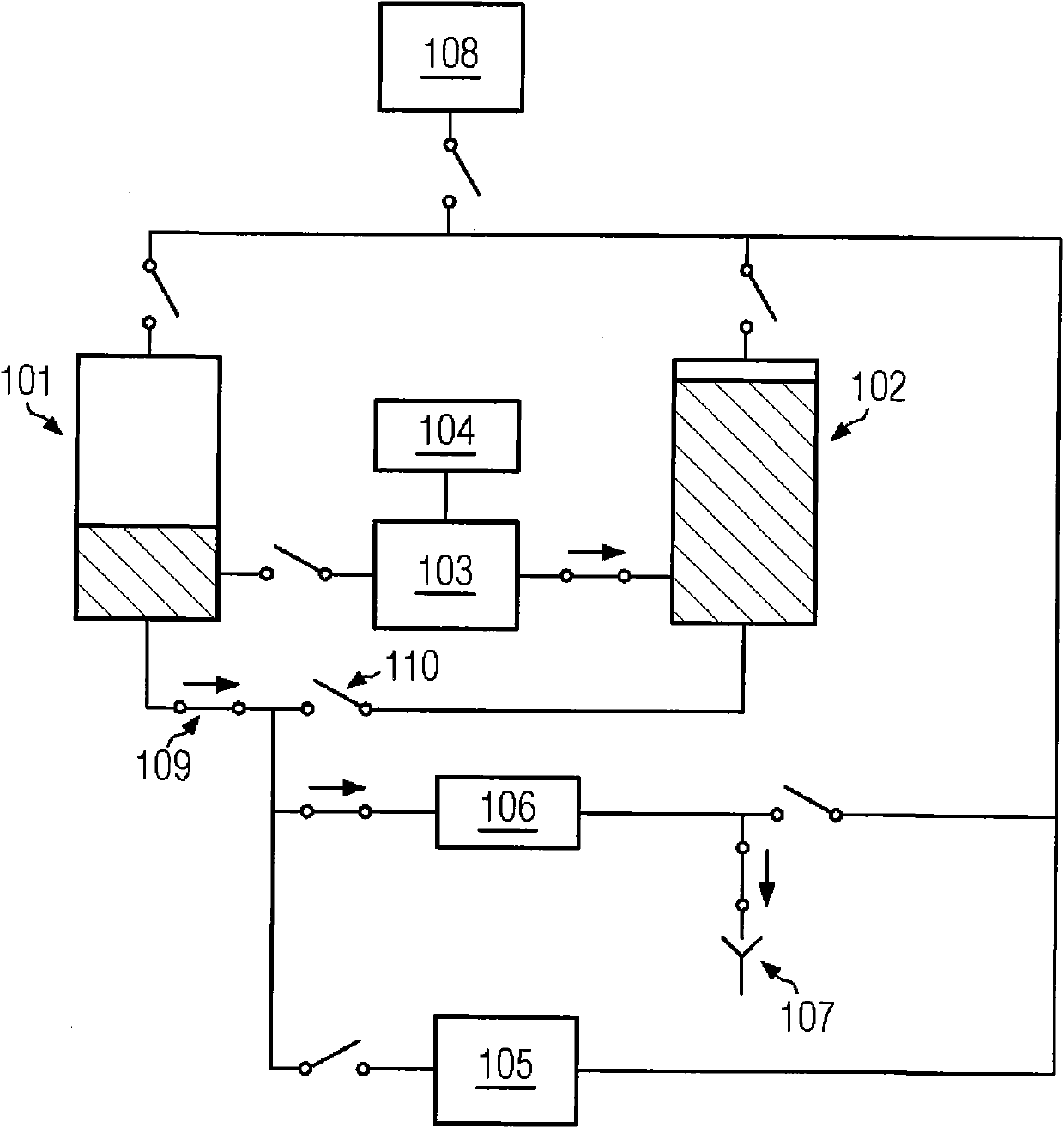

[0040] figure 1 Shown is a system comprising a filling system and a device for providing sterile liquid. The device for providing a sterile liquid comprises in particular a first liquid reservoir 101 and a second liquid reservoir 102 . In addition, the system comprises a sterilizing device comprising an element 104 for producing a sterilizing agent and for introducing the sterilizing agent into the first liquid in the first liquid reservoir 101 and / or into the second Element 103 of the second liquid in the liquid reservoir 102 .

[0041] In addition, the system comprises a filling system for filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com