Solid medicine crushing and stirring device for burn department

A stirring device and solid-state technology, which is applied in the field of solid-state drug crushing and stirring devices in the burn department, can solve the problem of not being able to quickly grind drug powder for use by the wounded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

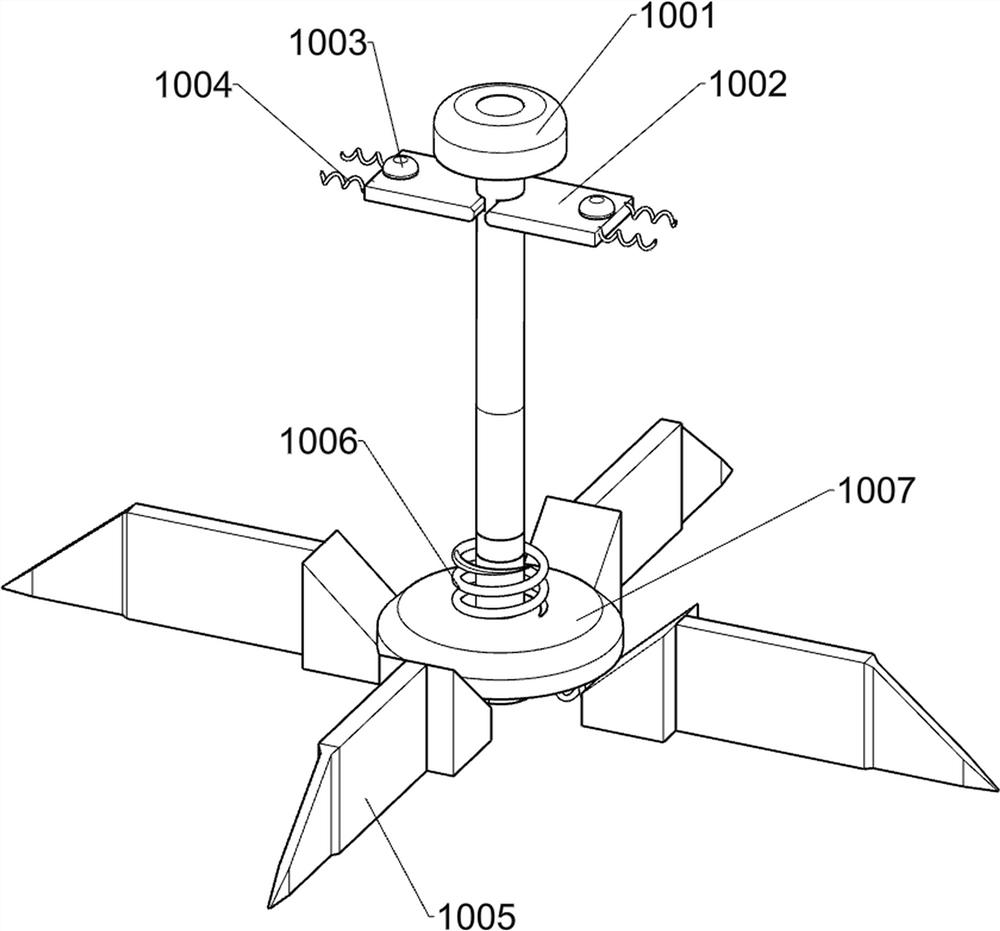

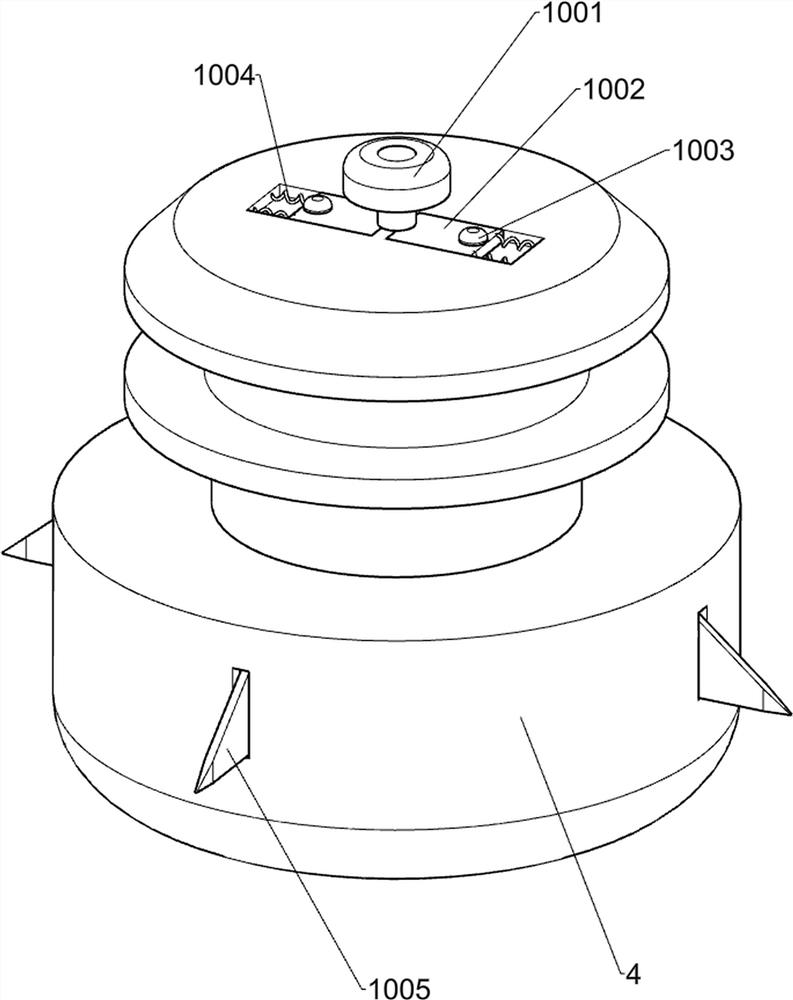

[0027] A solid-state drug pulverizing and stirring device in the department of burns, such as Figure 1-5 As shown, it includes a bracket 1, a pulverizing frame 2, a pedal 3, a pressing block 4, a pulverizing mechanism 5, a accommodating mechanism 6 and a stirring mechanism 7, two brackets 1 are arranged in the device, and a pulverizing mechanism 5 is arranged between the brackets 1 , the crushing mechanism 5 is provided with a crushing frame 2, the crushing mechanism 5 is provided with two pedals 3, the crushing mechanism 5 is provided with a pressing block 4, the bracket 1 is provided with a accommodating mechanism 6, and the lower side of the bracket 1 is connected with a Stirring mechanism 7.

[0028] The crushing mechanism 5 includes a connecting plate 51, a first rotating belt 52, a motor 53, a first guide block 54, a first guide rod 55, a first spring 56, a first ratchet rack assembly 57, a first ratchet gear 58, a first A torsion spring 59 and a first rotating rod 510...

Embodiment 2

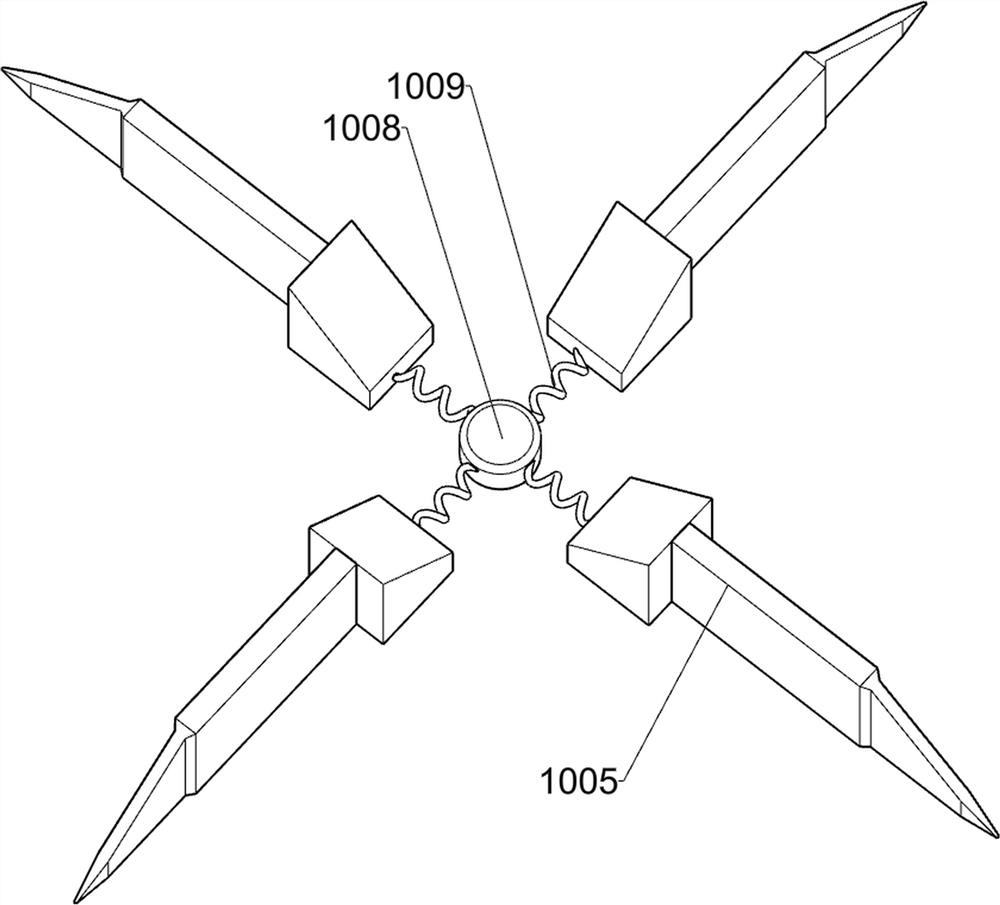

[0033] On the basis of Example 1, as figure 1 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it also includes a material blocking mechanism 8, and the material blocking mechanism 8 includes a mounting block 81, a second rotating rod 82, a baffle plate 83, a second ratchet gear 84, a second torsion spring 85, and a second ratchet rack assembly 86. and the first connecting block 88, the upper left side of the rear pedal 3 is provided with a first connecting block 88, the first connecting block 88 is provided with a second ratchet rack assembly 86, and the second ratchet rack assembly 86 is formed by the second ratchet rack. The rack is composed of two springs, the second rack is slidably connected to the rear pedal 3, the springs are connected between the second rack and the rear pedal 3, and the left side of the bracket 1 is provided with mounting blocks 81 , a second rotating rod 82 is rotatably connected between the mounting blocks 81, and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com