Fixture for machining knuckle backing pin hole

A steering knuckle and fixture technology, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unsuitable product quality assurance, high labor intensity of operators, and increase of accumulated errors, saving difficulty and cost. Low, the effect of solving the position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

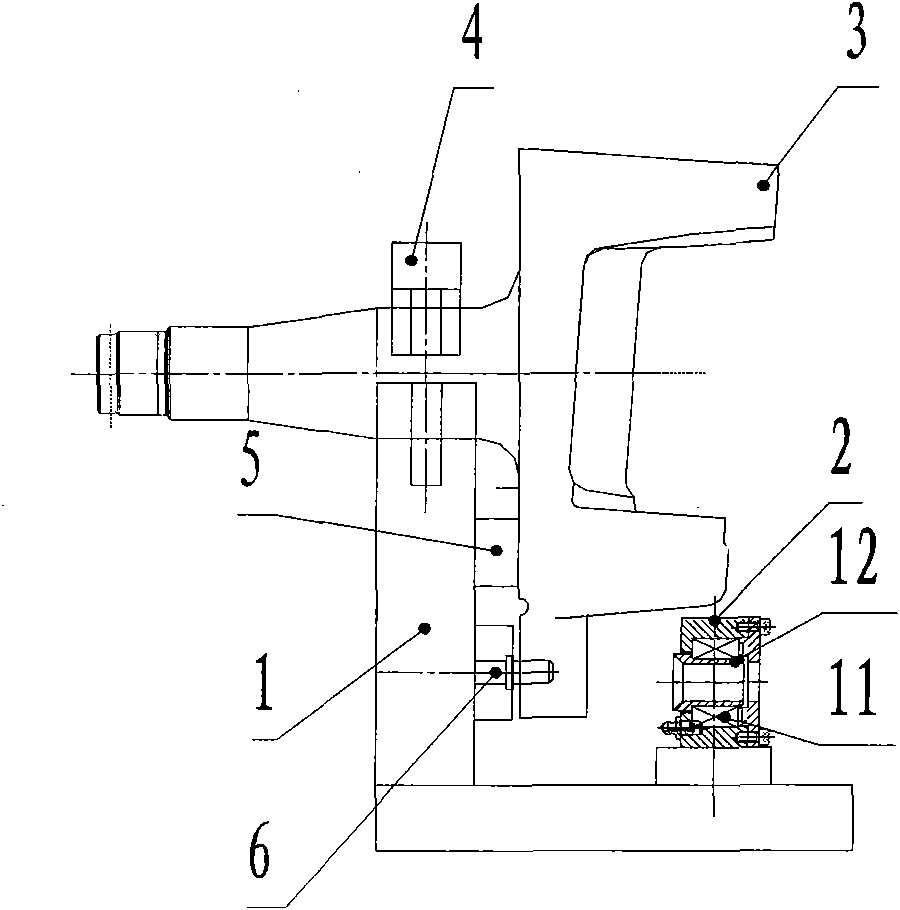

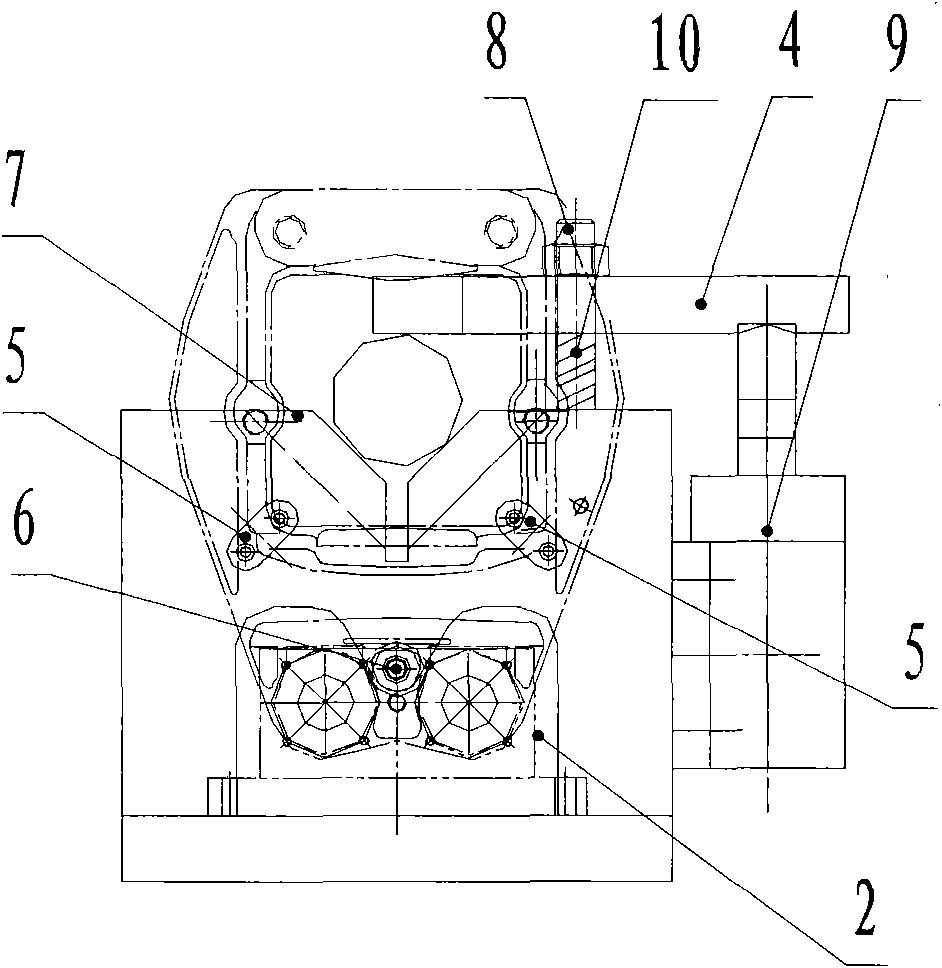

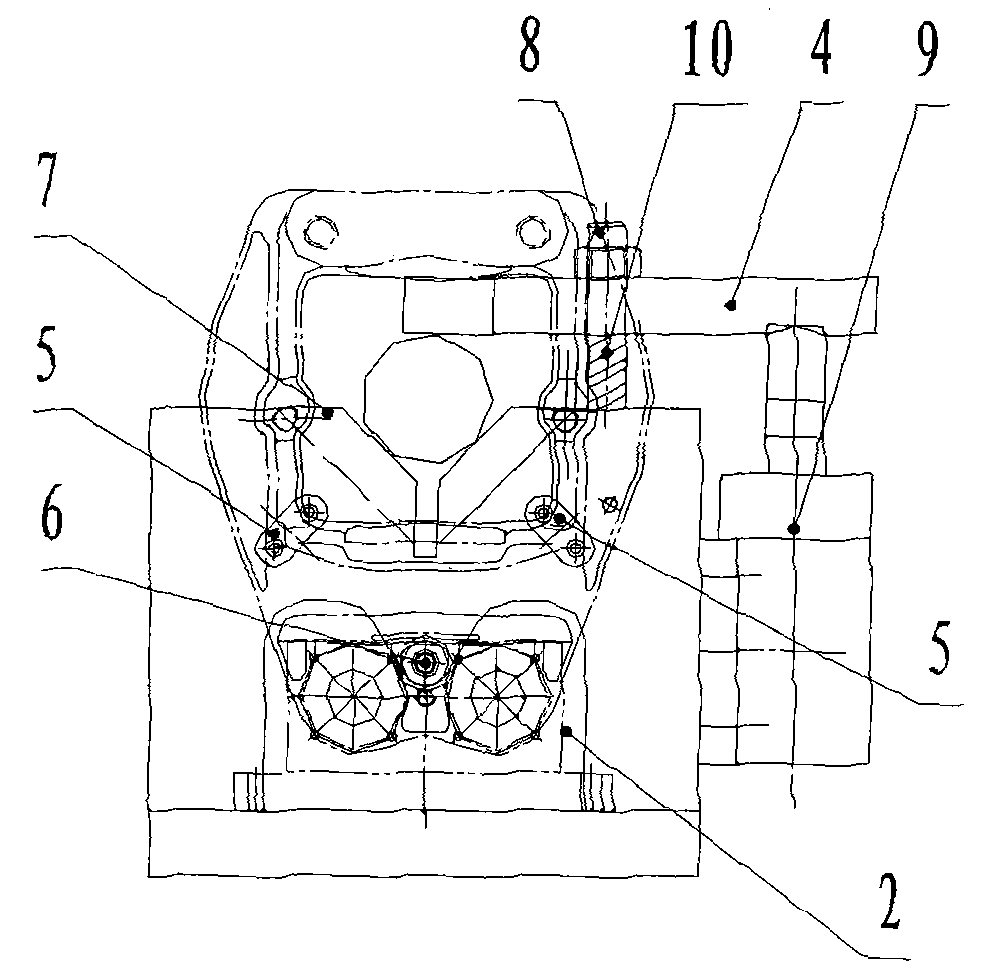

[0008] A fixture for processing steering knuckle support pin holes, which includes a clamp body 1, a guide bracket 2, a steering knuckle 3, a pressure plate 4, a positioning block 5, a positioning pin 6, a V-shaped block 7, an adjustment nut 8, a hydraulic cylinder 9, and a clamp Concrete 1 is provided with a steering knuckle 3, the main shaft of the steering knuckle 3 is provided with a pressure plate 4, a V-shaped block 7 is arranged under the main shaft of the steering knuckle 3, and a positioning block 5 is arranged between the large surface of the steering knuckle 3 and the clamp body 1 , the chuck body 1 is provided with a positioning pin 6, the positioning pin 6 is connected with the process hole of the steering knuckle 3, the chuck body 1 is provided with a hydraulic cylinder 9, the piston of the hydraulic cylinder 9 is connected with the pressure plate 4, and the pressure plate 4 is provided with an adjustment The bolt 8 and the adjusting bolt 8 are arranged on the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com