Adjustable-inclination angle bench clamp

A vise and fixed jaw technology, applied in vise, manufacturing tools, etc., can solve the problem that the vise cannot change the inclination angle of the clamped workpiece, and achieve the effect of improving labor productivity and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

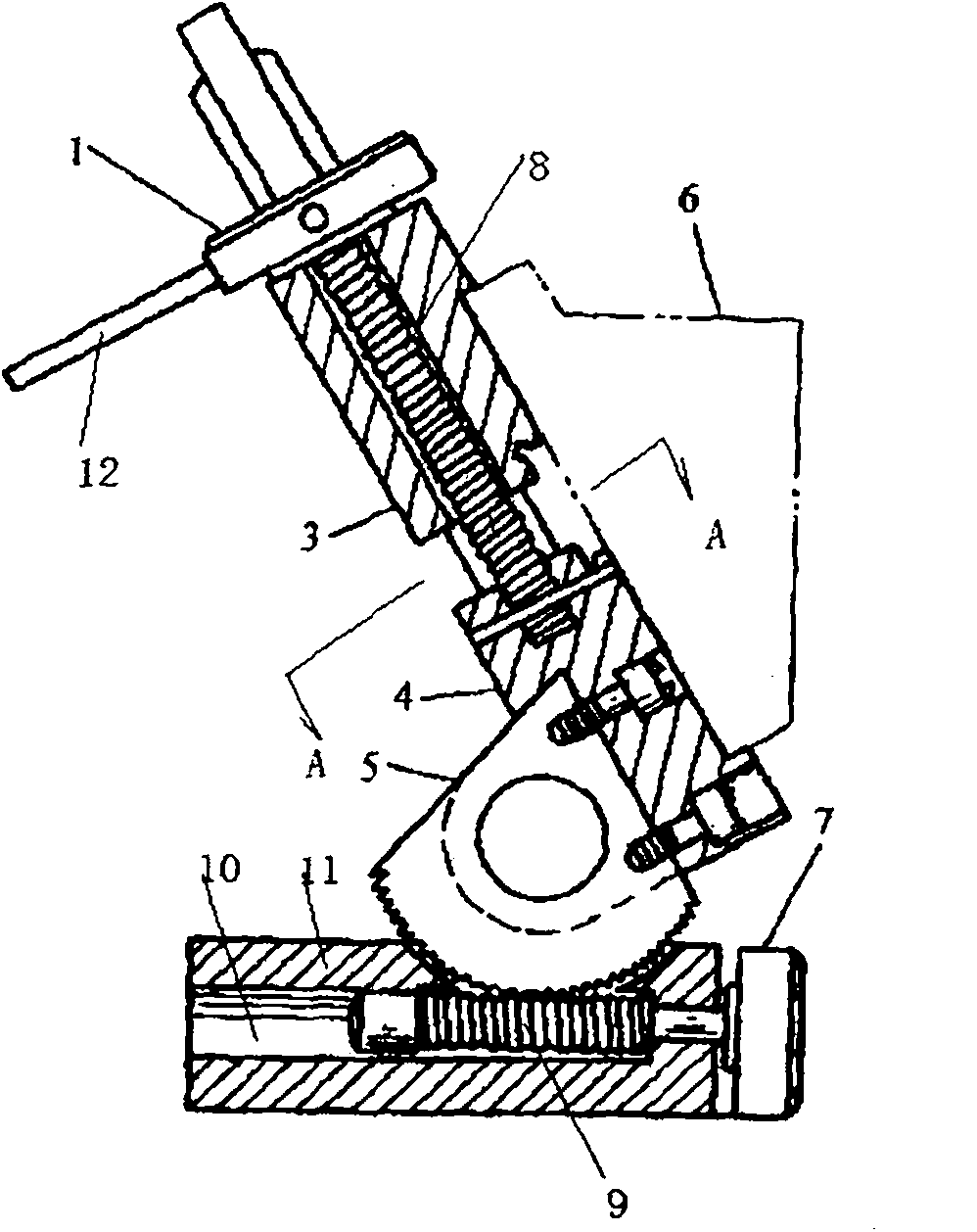

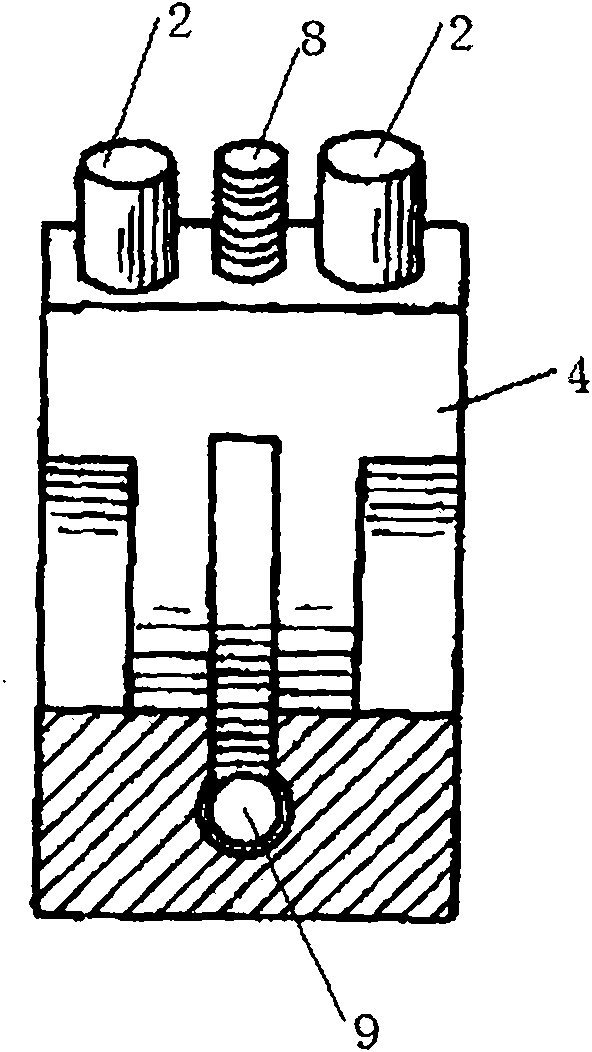

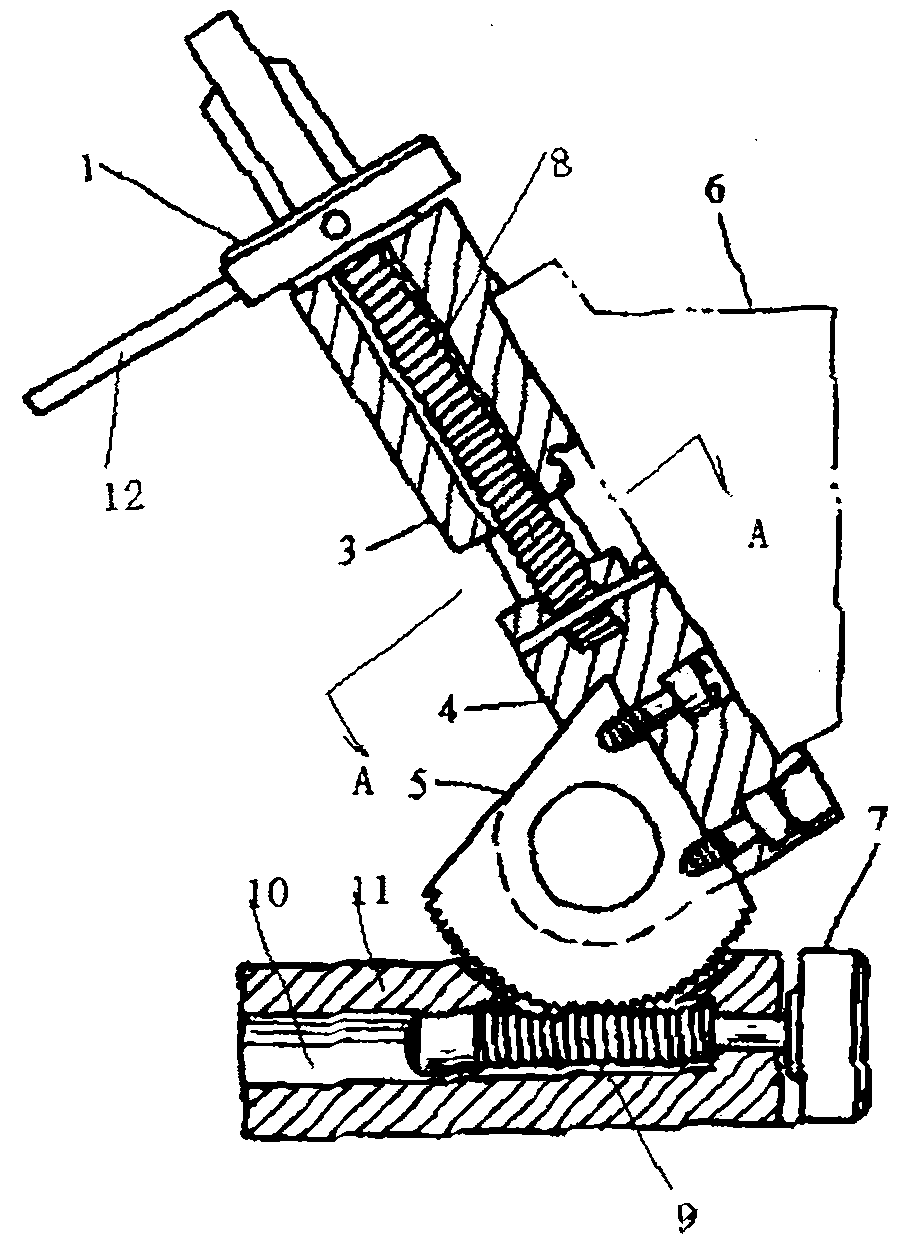

[0011] A vise with adjustable inclination angle of the present invention, such as figure 1 , figure 2 As shown, it is characterized in that it includes a base 12, a fixed jaw 4, a movable jaw 3, a screw mechanism and an inclination mechanism composed of a nut 1 and a screw 8, the fixed jaw 4 is hinged with the base 12, and the fixed jaw 4 Two guide pins 2 and screw rods 8 are fixed on the left and right sides, and three through holes matching the guide pins 2 and screw rods 8 are provided at corresponding positions on the movable jaw 3, and the guide pins 2 and screw rods 8 The movable jaws 3 are respectively located in the corresponding through holes, and the movable jaws 3 are guided through the cooperation of the through holes and the guide pins 2 , and the front end of the screw rod 8 is connected with the nut 1 .

[0012] Such as figure 1 As shown, the inclination mechanism includes a worm 9 and a fan-shaped worm gear 5, the worm gear 5 is fixedly connected to the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com