Pore forming method and pore forming part of special shape for connecting precast concrete units

A technology of precast concrete and special shape, which is applied in the direction of ceramic molding machines, etc., which can solve the problems affecting the service life of precast concrete components, the separation of precast concrete components, and unreliable connection, etc., to achieve easy construction quality assurance, enhanced connection effect, and connection performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

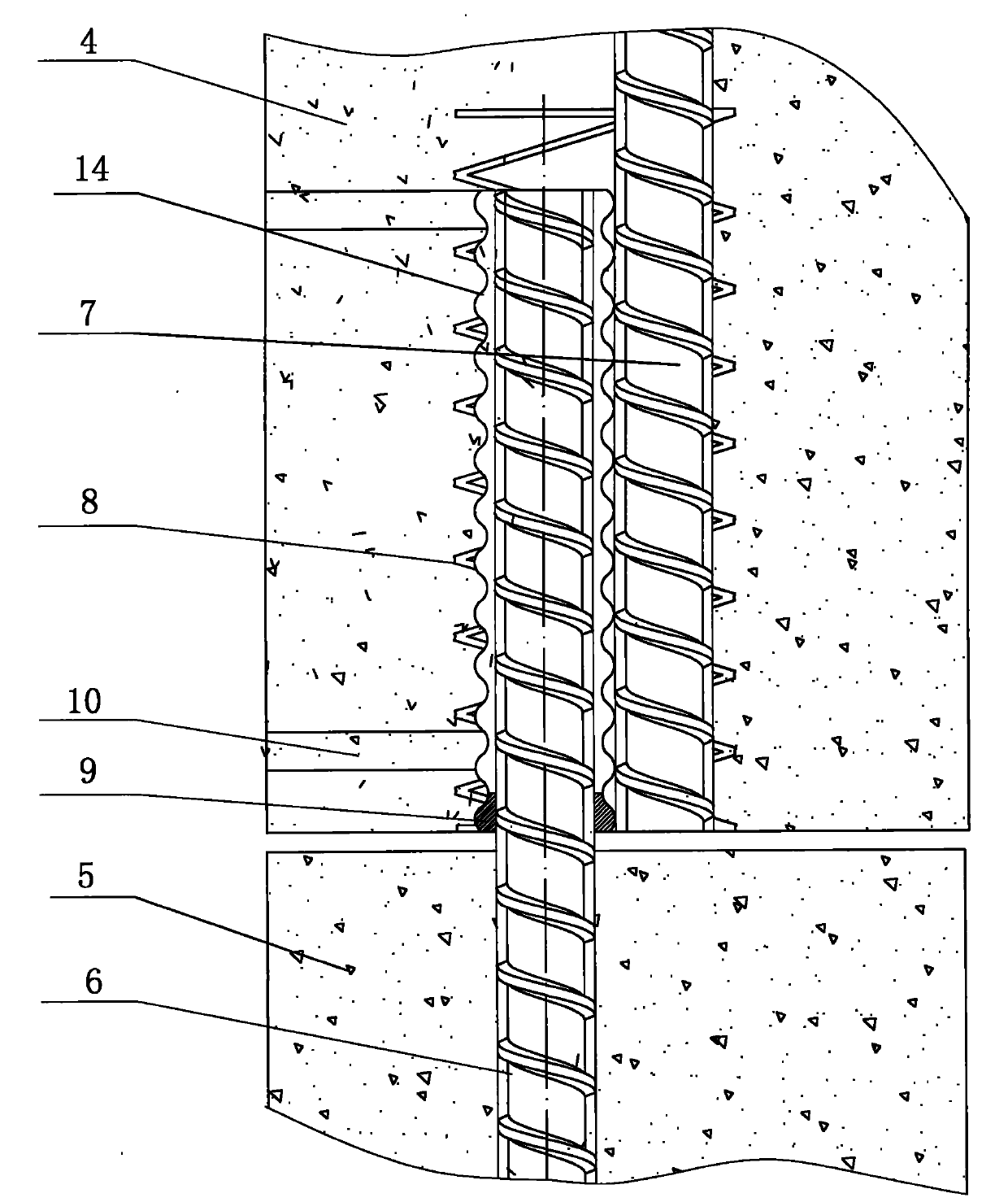

[0029] The method of forming holes with special shapes for the connection of precast concrete components. When making precast concrete components, precast concrete components need to reserve connection holes, and place embedded parts with specific hole types and specific shape surfaces in the reserved connection holes. Then pour the concrete components, before the concrete of the precast concrete components is finally set, the embedded parts are pulled out, so that the reserved connection holes have a specific hole type and a concave-convex surface of a specific shape in the holes, the reserved connection of the prefabricated concrete components Holes are used for connection and assembly between precast concrete components.

[0030] In the method for forming holes with special shapes for the connection of precast concrete components, the cross-sectional shape of the embedded part of the specific hole type is arc-shaped, polygonal, elliptical, or broken-line.

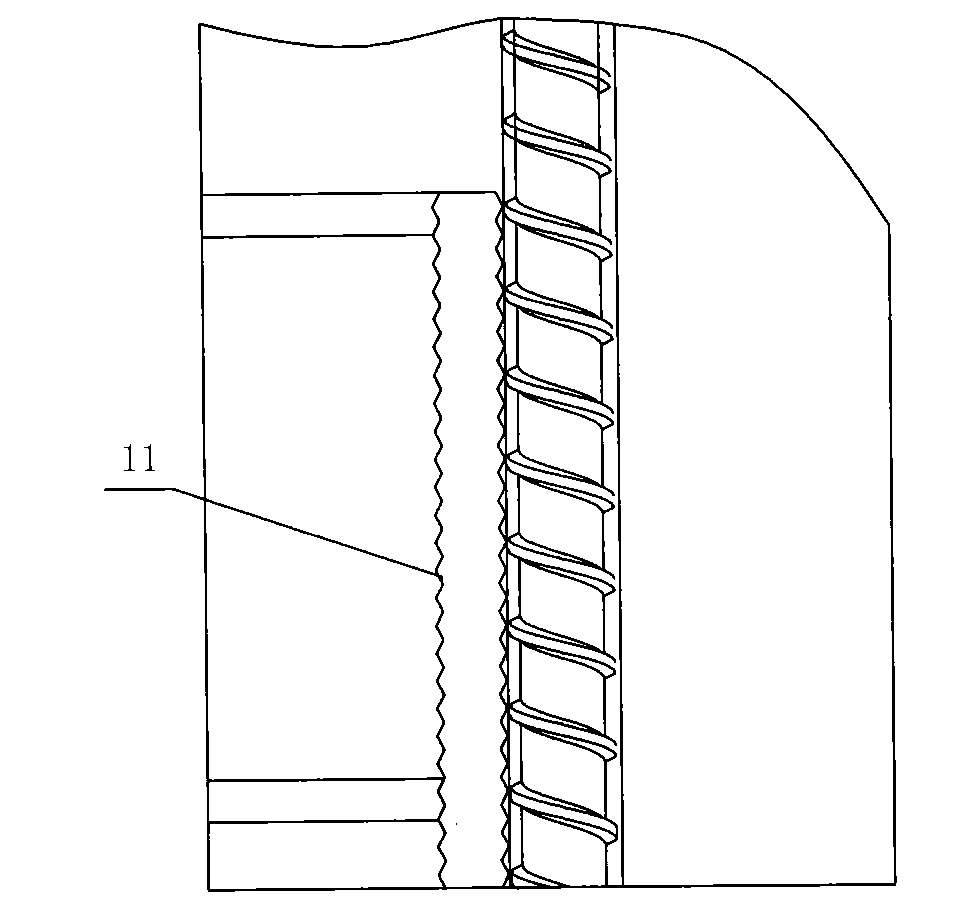

[0031] The surfa...

Embodiment 2

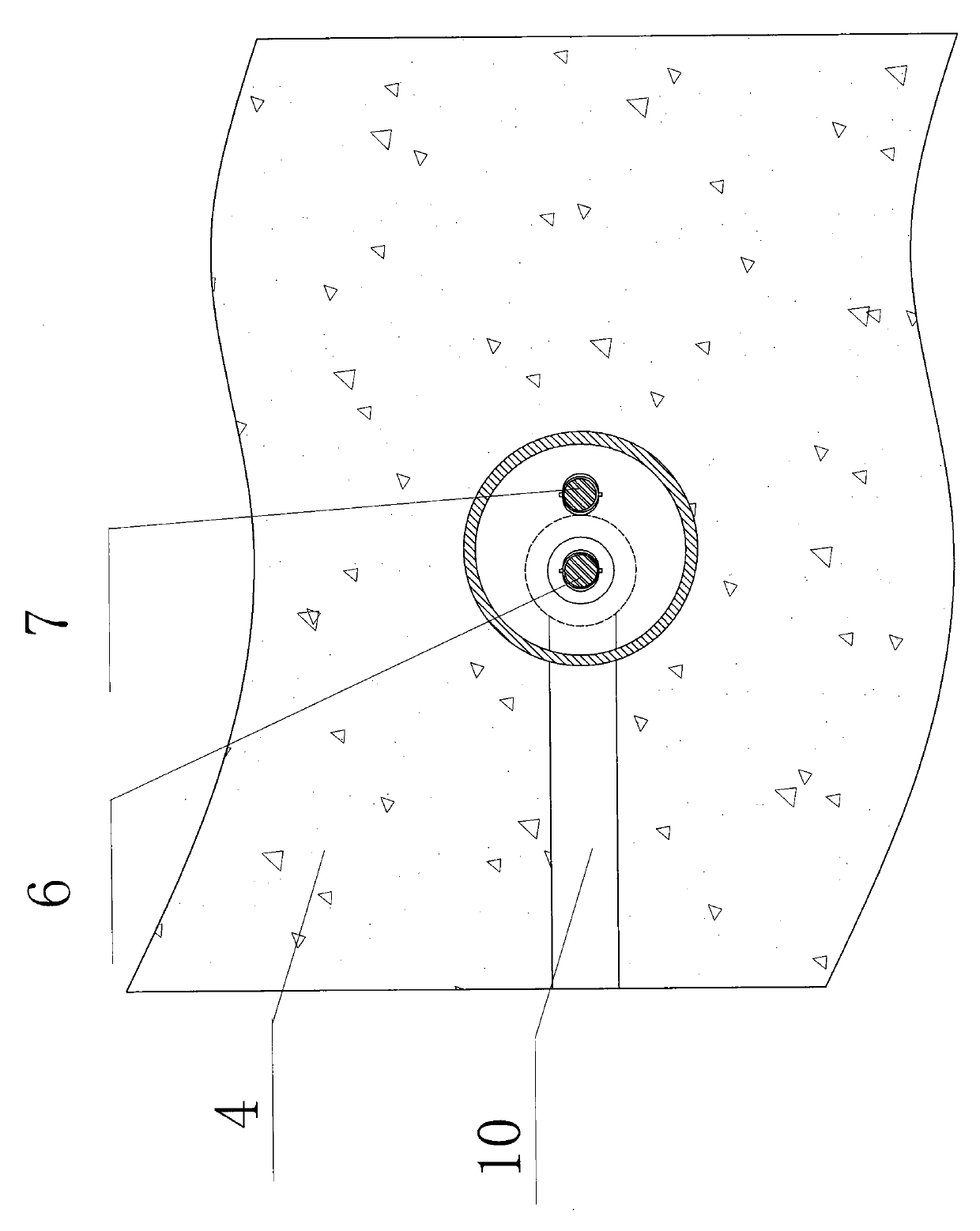

[0033] In the special-shaped hole-forming part for precast concrete components, the embedded part 1 includes a central drawing part 2 located in the center of the embedded part, and the central drawing part 2 surrounds the assembly 3, The described assembly is a set.

[0034] As for the special-shaped hole-forming part used for precast concrete components, the cross-sectional shape of the embedded part includes circular, square, elliptical, arc-shaped, polygonal or broken-line shapes.

[0035] The shape of the outer surface of the assembly is a corrugated surface or a grooved surface or a spiral surface or a dotted surface.

[0036] The method of using prefabricated concrete components with special holes for building construction, the prefabricated concrete components 4 and the connected prefabricated concrete components 5 are placed, the connecting steel bars 6 and pre-embedded steel bars 7 are placed, and the reinforcement bars 8 are inserted. Put the sealing ring 9 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com