Mixed feeding device for extrusion and dehumidification of wood and plastics

A feeding device and wood-plastic technology, which is applied in the field of feeding devices, can solve the problems of mixing technical problems such as expanding the application of wood-plastic composite materials, and achieve the effects of reducing floor space, avoiding uneven mixing, and improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following further description with reference to the drawings does not limit the scope of the present invention.

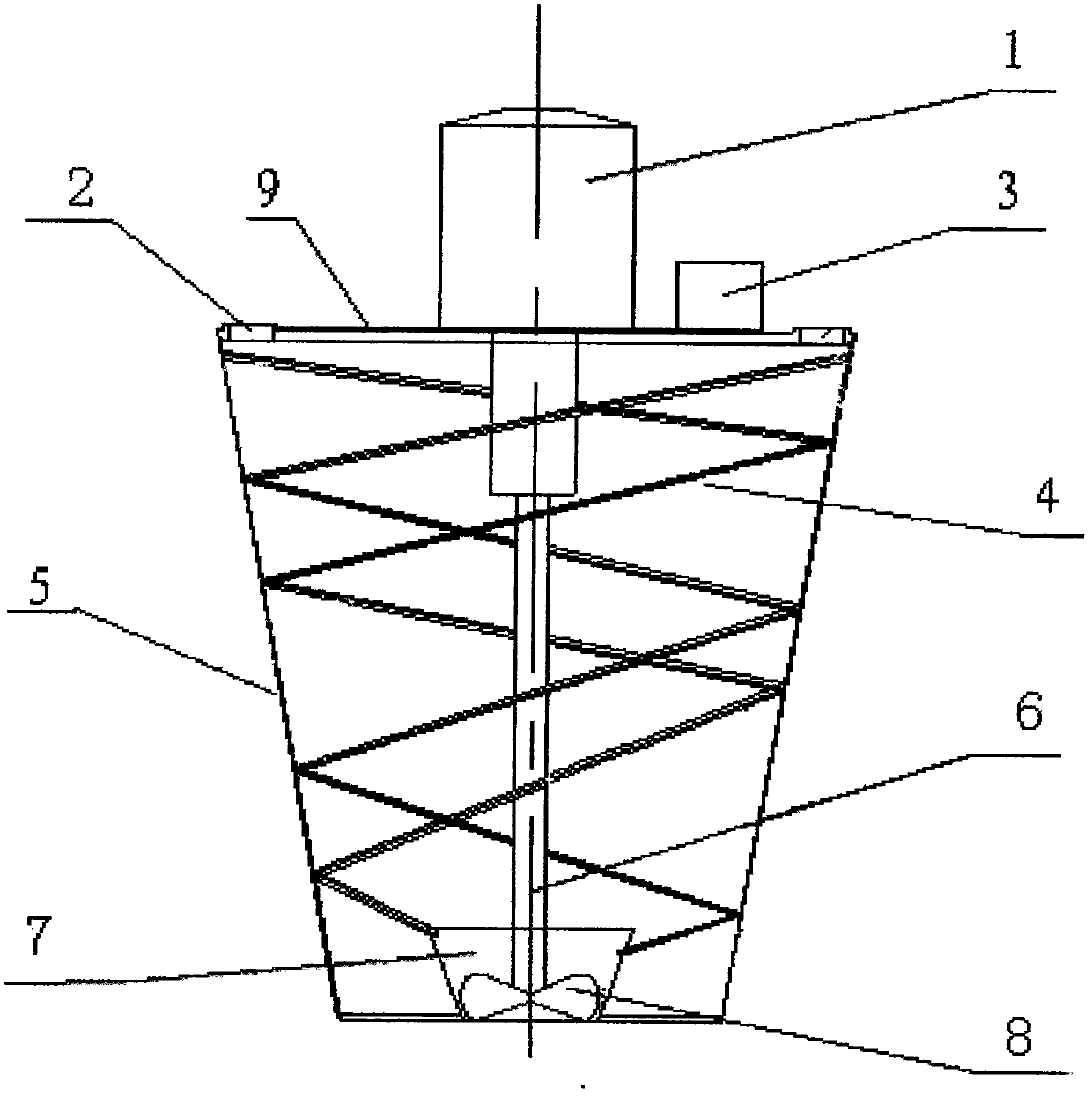

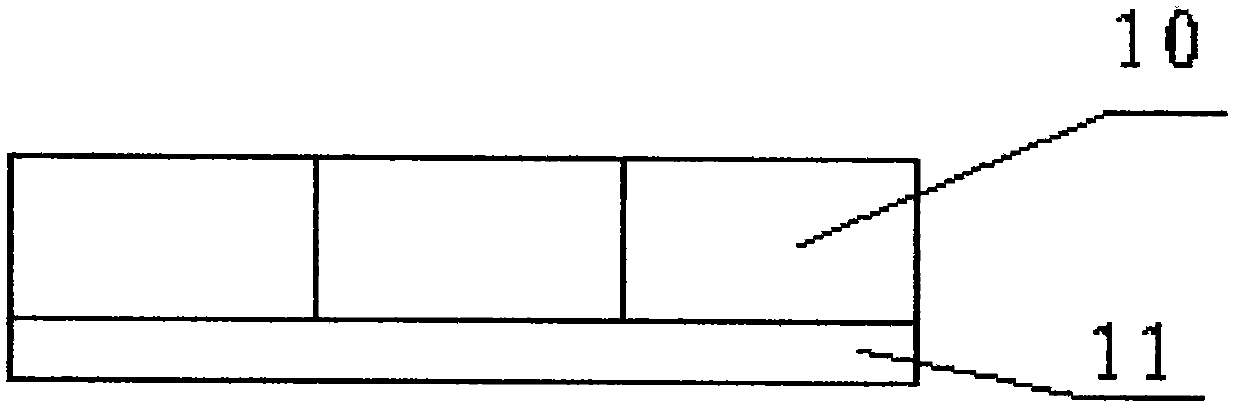

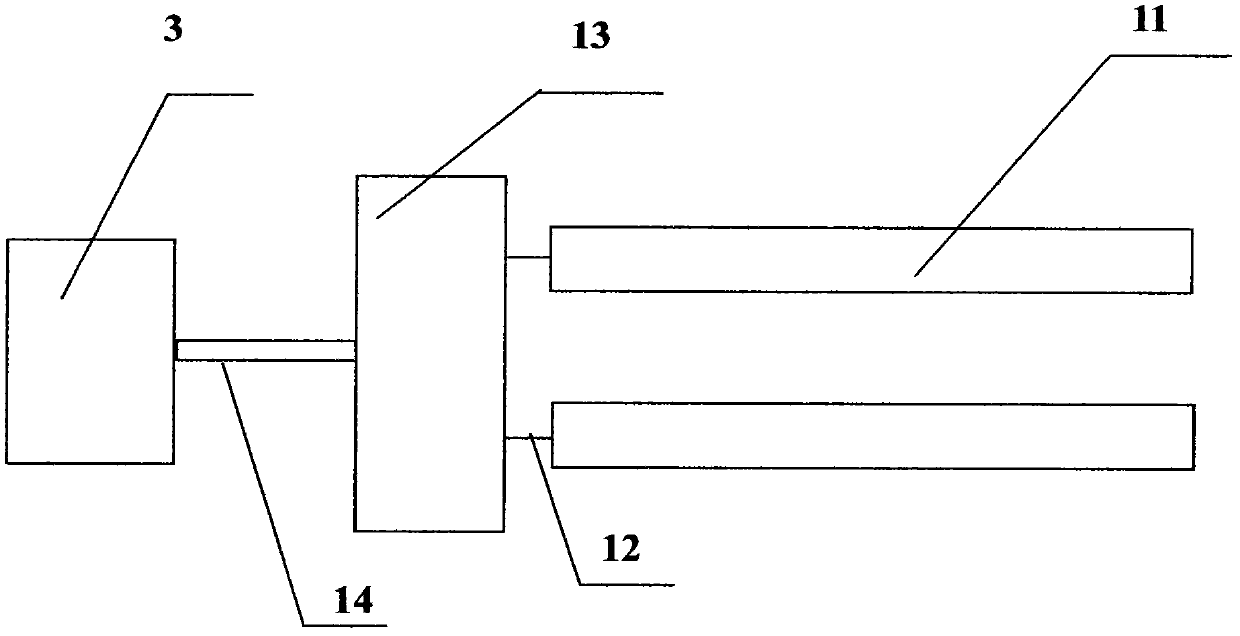

[0019] See figure 1 with figure 2 As shown, in the barrel 5 of the feeding hopper of the wood-plastic extruder, two or more spiral trough slides 4 from top to bottom are provided, and the bottom of the spiral trough slide 4 is provided with a heating plate 11, The heating plate is controlled by a thermostat 3, which can control the heating plates 11 of multiple spiral trough slides 4 at the same time. The material is fed from the feeding port 2, and multiple feeding ports 2 can be set. The material slides down the spiral trough 10, and while it slides, since the heating plate 11 is working under temperature control conditions, the material on it is sliding at the same time It is heated, dehumidified and dried. When the two materials fall from the top to the bottom, they enter the mixing chamber 7. The mixing shaft 6 of the mixing chamber 7 drives the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com