Water and electricity linkage device of fully automatic concrete high-speed spraying machine

A technology of linkage device and spraying machine, which is applied in shaft equipment, earthwork drilling and processing of building materials, etc. It can solve problems such as water supply hydraulic pressure detection, uneven slurry mixing, and affecting construction quality, so as to achieve stable water flow and ensure Effect of mixing quality and saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

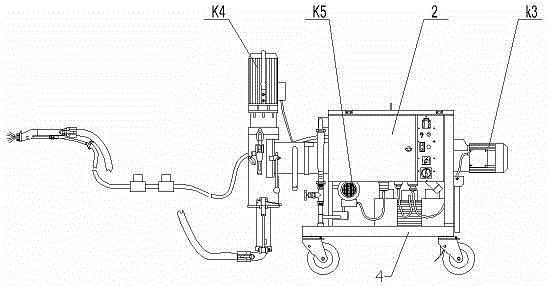

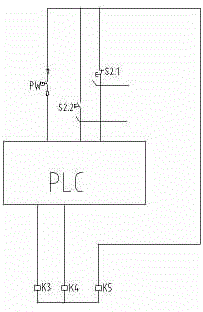

[0017] Examples such as figure 1 , figure 2 As shown, a hydropower linkage device of a fully automatic concrete high-speed spraying machine includes a frame 4, and the frame 4 is equipped with an I-level mixing system power unit, a II-level mixing system power unit, and an I-level mixing system power unit transmission It is connected with a Class I mixing system, and the frame 4 is also equipped with a water delivery power device and a PLC control system. The detection element PW, the power unit of the I-level mixing system, the power unit of the II-level mixing system, the water delivery power unit and the water pressure detection unit PW are respectively electrically connected to the PLC control system.

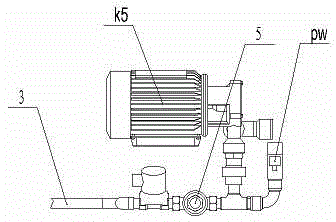

[0018] A pressure stabilizing valve 5 is also installed on the waterway 3, the power unit of the I-level mixing system is the conveying motor K3, and the power unit of the II-level mixing system is the pumping motor K4, such as image 3 As shown, the water delivery power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com