A kind of preparation method of breathable anti-seepage sand

A technology of anti-seepage sand and raw sand, applied in botany equipment and methods, planting substrates, gardening, etc. Solve problems such as soil water permeability and other problems, achieve excellent fluidity, good application prospects, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

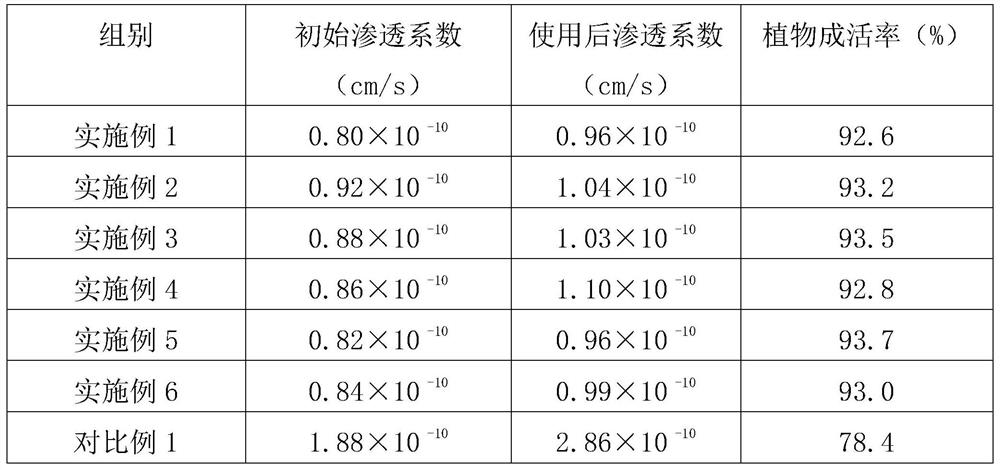

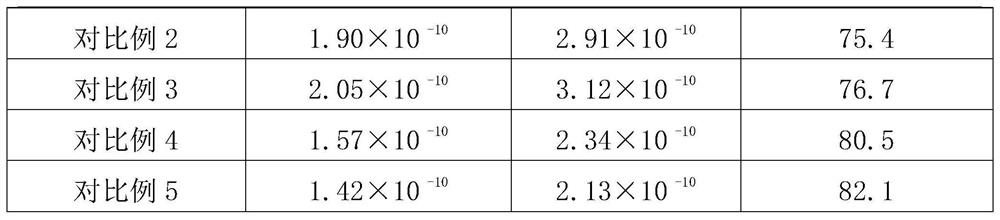

Examples

Embodiment 1

[0024] A breathable anti-seepage sand, comprising the following components by mass fraction: 94% of raw sand, 0.5% of modified glass fiber, 1% of fluorosilicone surfactant, 0.2% of sodium bentonite, 0.3% of diatomite powder, attapulgite Clay powder 0.2%, white carbon black 0.3%, paraffin 3.5%.

[0025] The preparation method of the air-permeable anti-seepage sand in the present embodiment comprises the following steps:

[0026] (1) After mixing the modified glass fiber and the fluorosilicone surfactant, add it to a stirring tank and stir evenly at a stirring rate of 40 rpm for 10 minutes to obtain a mixture A;

[0027] (2) Mix sodium-based bentonite, diatomite powder, attapulgite clay powder, and white carbon black into a mixing tank and stir evenly at a stirring rate of 400 rpm for 5 minutes to obtain a mixture B;

[0028] (3) Stir and mix mixture A, mixture B and raw sand, and add paraffin wax in two times according to the volume ratio of 3:2 during the stirring process. Wh...

Embodiment 2

[0031] A breathable anti-seepage sand, including the following components in mass fractions: 91% of raw sand, 0.5% of modified glass fiber, 1% of fluorosilicone surfactant, 1% of sodium bentonite, 1% of diatomite powder, attapulgite Clay powder 0.2%, white carbon black 0.3%, paraffin 5%.

[0032] The preparation method of the air-permeable anti-seepage sand in the present embodiment comprises the following steps:

[0033] (1) After mixing the modified glass fiber and the fluorosilicone surfactant, add it into the stirring tank and stir evenly, the stirring rate is 80 rpm, and the stirring time is 20min, to obtain the mixture A;

[0034] (2) Mix sodium-based bentonite, diatomite powder, attapulgite clay powder, and white carbon black and add them into a stirring tank and stir evenly at a stirring rate of 600 rpm for 12 minutes to obtain a mixture B;

[0035] (3) Stir and mix mixture A, mixture B and raw sand, and add paraffin wax in two times according to the volume ratio of 3...

Embodiment 3

[0038] A breathable anti-seepage sand, including the following components in mass fraction: 92% of raw sand, 0.5% of modified glass fiber, 0.5% of fluorosilicone surfactant, 1% of sodium bentonite, 1% of diatomite powder, attapulgite Clay powder 1%, white carbon black 1%, paraffin 3%.

[0039] The preparation method of the air-permeable anti-seepage sand in the present embodiment comprises the following steps:

[0040] (1) After mixing the modified glass fiber and the fluorosilicone surfactant, add it into a stirring tank and stir evenly at a stirring rate of 50 rpm for 12 minutes to obtain a mixture A;

[0041](2) Mix sodium-based bentonite, diatomite powder, attapulgite clay powder, and white carbon black into a mixing tank and stir evenly at a stirring rate of 450 rpm for 7 minutes to obtain a mixture B;

[0042] (3) Stir and mix mixture A, mixture B and raw sand, and add paraffin wax in two times according to the volume ratio of 3:2 during the stirring process. When addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com