A composite polymer of polyconjugated diene→s and sibs and its preparation and application in asphalt modification

A polyconjugated diene and composite polymer technology, which is applied in building construction, climate change adaptation, rolling resistance optimization, etc. Mature process, the effect of improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

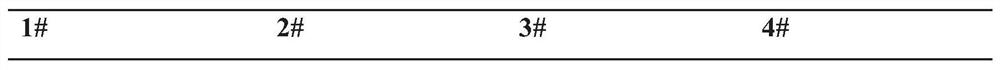

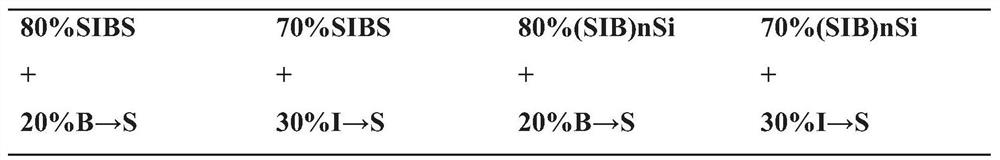

Examples

Embodiment 1

[0075] Synthetic Linear SIBS

[0076]Add 2500ml of cyclohexane and 0.1ml of tetrahydrofuran with a water content of less than 20mg / kg to a 5-liter polymerization kettle, stir and heat up to 50-60°C, add 37.5g of styrene, and then add 0.6mol / L of n-butyllithium 3.2 ml initiates styrene, reacts for 20-25 minutes, presses (B / I=7 / 3) 122.5g butadiene and 52.5g isoprene into the measuring tank with N2, and mixes evenly, and then slowly and continuously presses the mixed monomers. Put it into the polymerization kettle for two-stage polymerization, control the feeding time for 30 minutes, control the reaction temperature at 70-75°C, and the reaction time for 30-45 minutes, then add 37.5g of styrene to carry out three-stage polymerization, after 20-25 minutes, add 0.45g BHT containing The cyclohexane solution was used to terminate the active glue solution, that is, a linear SIBS glue solution with a mass concentration of 12.5% was obtained, Mn=132,000, and its 1,4-addition content wa...

Embodiment 2

[0078] Synthetic star SIBS

[0079] According to the steps and conditions of Example 1, add 6.4 ml of n-butyllithium with a concentration of 0.6 mol / L, first polymerize a section of 75 g of styrene, then slowly and continuously press in a mixture of 122.5 g of butadiene and 52.5 g of isoprene, In the third section, 2.5ml of 0.4mol / L silicon tetrachloride was added for coupling, the coupling time was 10-20min, and then the active glue solution was terminated by adding a cyclohexane solution containing 0.13g BHT to obtain a star with Mn=265,000 (SI / B)nSi glue, the content of 1,4-addition is 90.4%, and the mass concentration of glue is 12.5%.

Embodiment 3

[0081] Synthesize B→S

[0082] 2500ml of cyclohexane and 0.1ml of tetrahydrofuran with a water content of less than 20mg / kg were added to a 5-liter polymerization kettle, and the temperature was raised to 55-65°C with stirring. Ethylene, 75g styrene and 12.5ga-methylstyrene were mixed uniformly in the metering tank, the mixture was pressed into the polymerization kettle at one time, the reaction temperature was controlled at 55-75°C, and the reaction time was 30-45min, and then the mixture containing 0.31 The cyclohexane solution of gBHT terminates the active glue to obtain the poly B→S glue. The measured Mn=182,000, the 1,4-addition content is 91.5%, and the mass concentration of the glue is 12.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com