Composite polymer of polyconjugated diene-S and SIBS, preparation for composite polymer and application of composite polymer in asphalt modification

A polyconjugated diene, composite polymer technology, applied in building construction, climate change adaptation, rolling resistance optimization, etc., can solve the problem of no improvement in other properties of modified asphalt, and achieve excellent high and low temperature performance and storage stability. good resistance to rutting and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

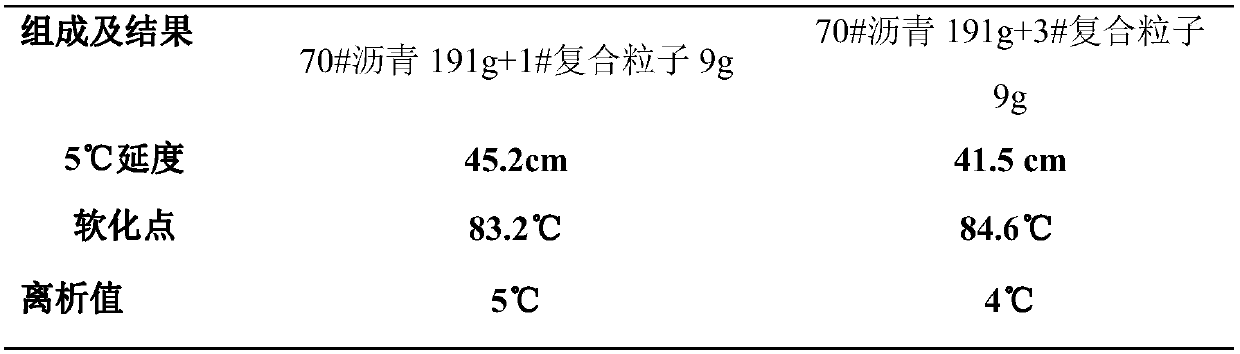

[0075] synthetic linear SIBS

[0076]Add 2500ml of cyclohexane with a water content of less than 20mg / kg and 0.1ml of tetrahydrofuran into a 5-liter polymerization kettle, stir and heat up to 50-60°C, add 37.5g of styrene, and then add 0.6mol / L of n-butyllithium 3.2 Initiate styrene in ml, react for 20-25min, press into the metering tank with N2 (B / I=7 / 3) 122.5g butadiene and 52.5g isoprene mix evenly, and then slowly and continuously press the mixed monomer Put it into the polymerization kettle for two-stage polymerization, control the feeding time for 30 minutes, control the reaction temperature at 70-75°C, and the reaction time is 30-45 minutes, then add 37.5g of styrene for three-stage polymerization, after 20-25 minutes, add 0.45g of BHT The cyclohexane solution terminates the active glue, and the linear SIBS glue with a mass concentration of 12.5% is obtained, and the measured Mn=132,000, and its 1,4-addition content is 90.2%.

Embodiment 2

[0078] synthetic star SIBS

[0079] According to the steps and conditions of Example 1, add 6.4ml of n-butyllithium with a concentration of 0.6mol / L, first polymerize 75g of styrene, and then slowly and continuously press into the mixture of 122.5g of butadiene and 52.5g of isoprene, In the third stage, add 2.5ml of 0.4mol / L silicon tetrachloride for coupling, the coupling time is 10-20min, and then add cyclohexane solution containing 0.13gBHT to terminate the active glue, and obtain the star shape with Mn=265,000 (SI / B) nSi glue, 1,4-addition content of 90.4%, glue mass concentration of 12.5%.

Embodiment 3

[0081] Synthesize B→S

[0082] Add 2500ml of cyclohexane and 0.1ml of tetrahydrofuran with a water content of less than 20mg / kg into a 5-liter polymerization kettle, stir and raise the temperature to 55-65°C, add 2.3ml of 0.6mol / 1 n-butyllithium, and dissolve 162.5g of butane Mix ethylene, 75g styrene and 12.5ga-methylstyrene in a metering tank evenly, press the mixture into the polymerization kettle at one time, control the reaction temperature at 55-75°C, and the reaction time for 30-45min, then add 0.31 The cyclohexane solution of gBHT terminates the active glue to obtain poly B→S glue, with Mn=182,000, 1,4-addition content of 91.5%, and glue mass concentration of 12.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com