Gate sealing valve

A technology of sealing valve and gate, applied in the field of gate sealing valve, can solve the problems of low production level of ball valve, incomplete cleaning, easy clamping of butterfly valve, etc., and achieve the effect of shortening production cycle, compact structure and enhanced sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

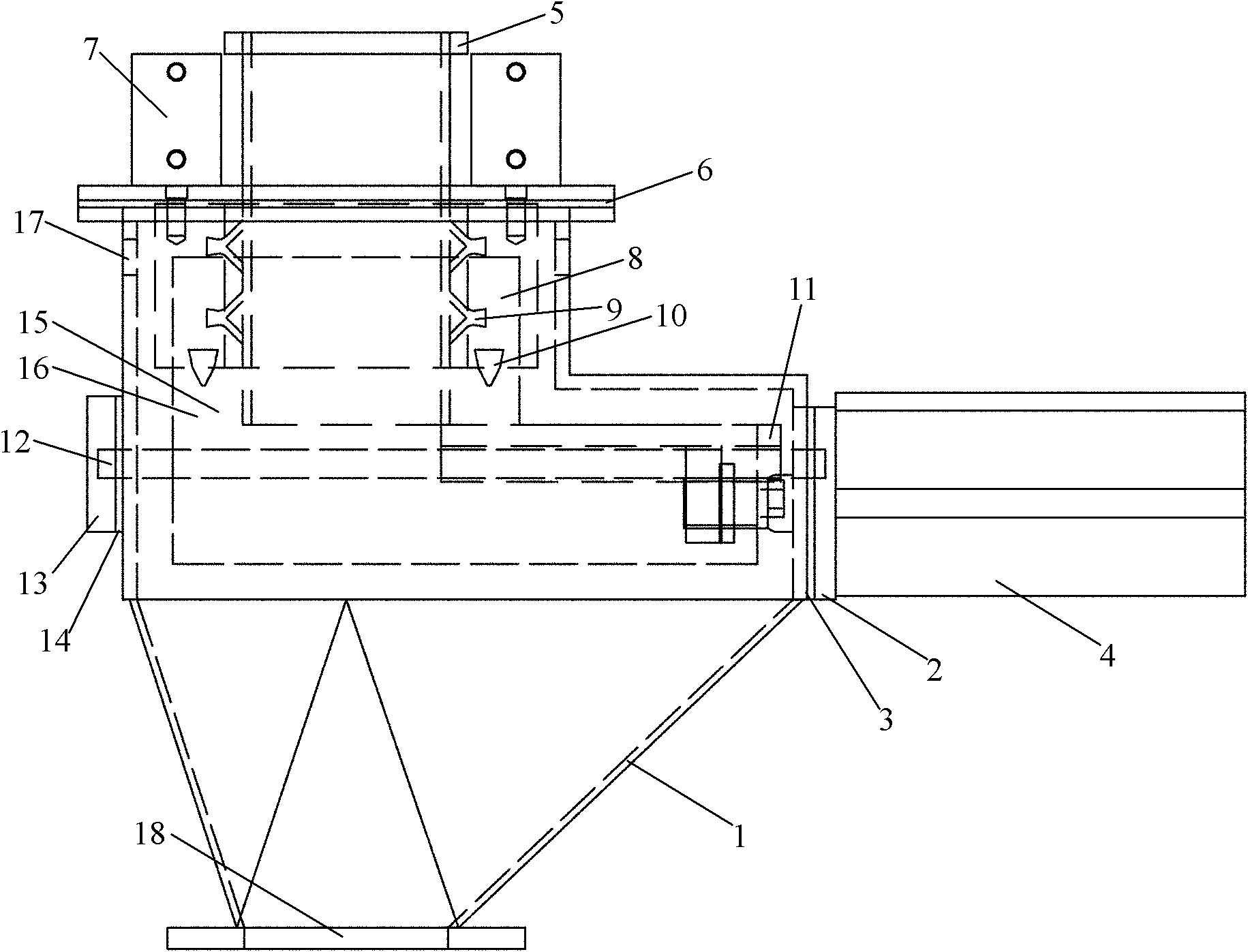

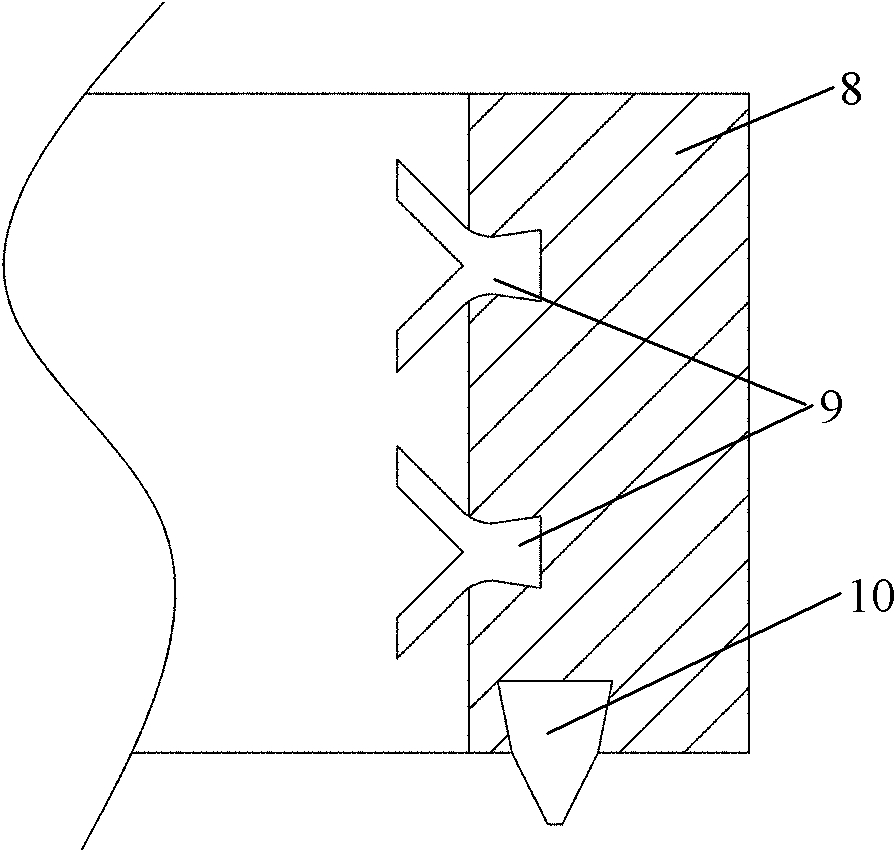

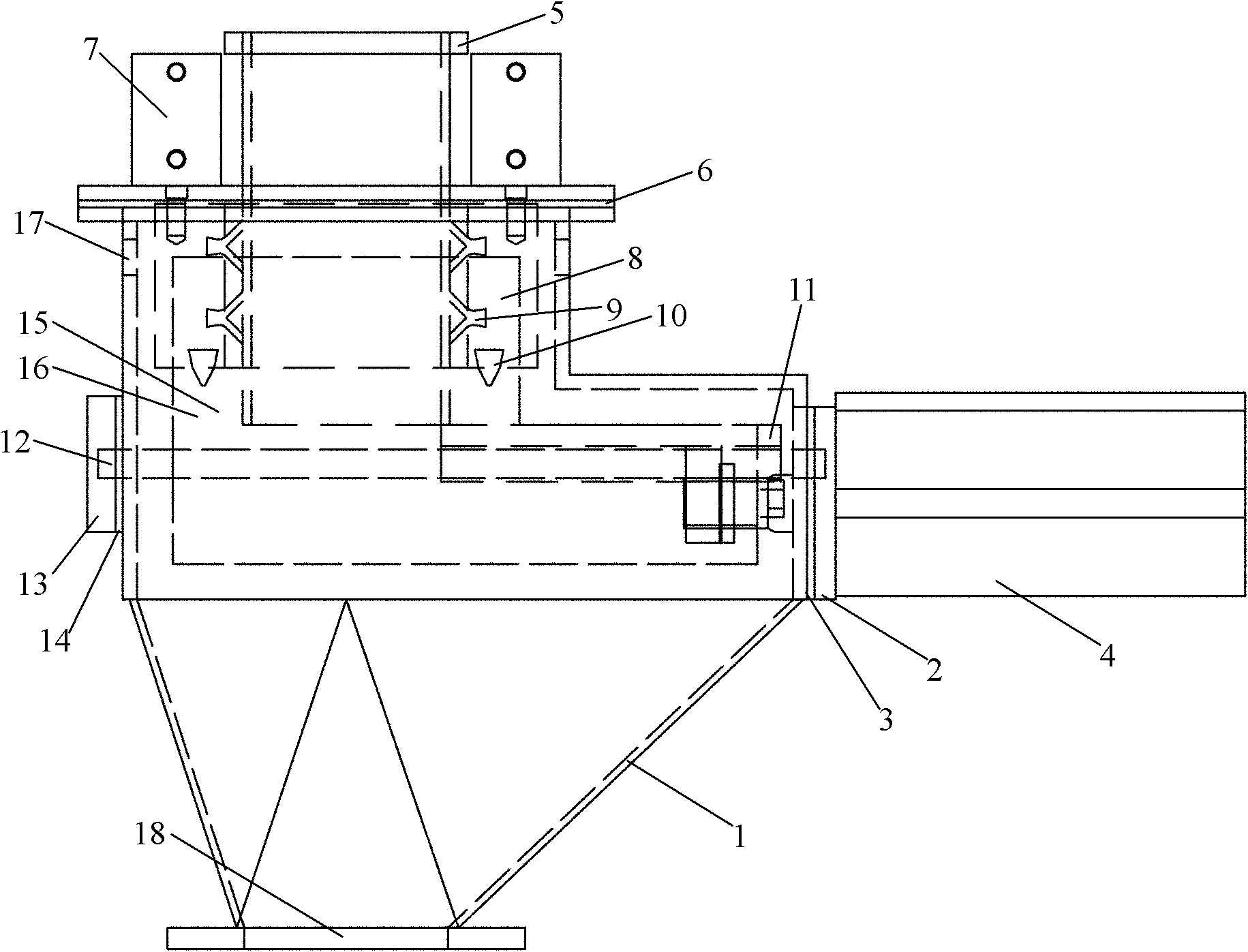

[0028] See Figure 1-2 As shown, the gate sealing valve of the present invention includes a housing 1, a feed pipe 5, a sealing member, a material retaining member 11, a sealing driving part 7, and a material retaining driving part 4, and the feed pipe 5 is inserted in the In the casing 1, the casing 1 is provided with a discharge port 18, the sealing driving part 7 and the blocking driving part 4 are both sealed and arranged on the casing 1, and the blocking part 11 and The sealing parts are all arranged in the housing 1, and the stopper driving part 4 is connected to the stopper part 11 for driving the stopper part 11 to cut off or communicate with the feed pipe 5 and the The passage between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com