Motor-driven magnetic coupling non-contact rope drum for deep water

A motor-driven, non-contact technology, applied in the direction of electric components, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

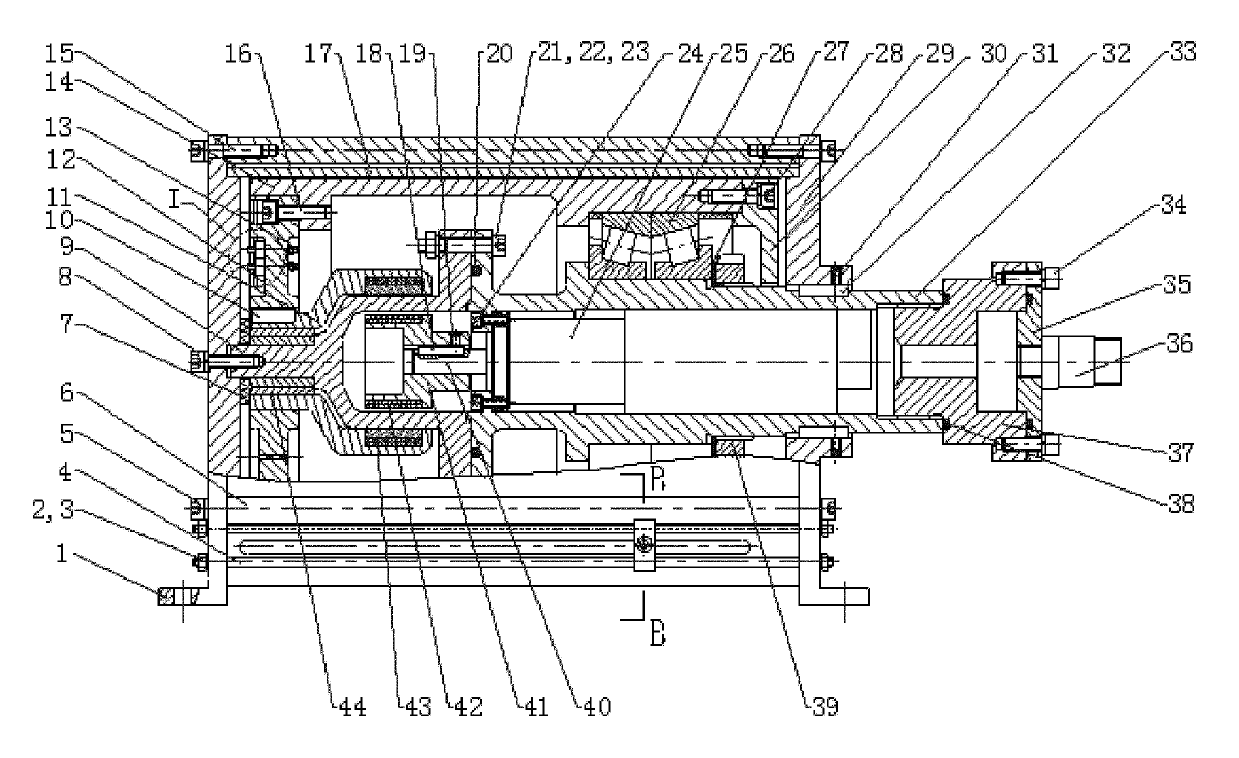

[0014] The motor-driven magnetic coupling non-contact cable reel for deep water is mainly used in the winding operation of steel wire rope, cable, optical cable, hose, wire rope and other flexible cables in the range of 1500-10000 meters in water depth. In the embodiment of this design, the object to be wound is a steel wire rope with a diameter of φ3mm and a length of 30m. The structure is as follows: figure 1 As shown, the basic design parameters are: specification (length×width×height): 450×280×300mm; weight: 40kg. Other design parameters are: motor output shaft 40 diameter φ15mm; rolling bearing 26 type: 30220; drum 14 outer diameter: φ220mm; end cover support rod 6 diameter: φ16mm; guide post 4 diameter: φ5mm; inner rotor 41 outer diameter: φ56mm; Outer rotor 11 inner diameter: φ82mm; stator 9 outer diameter: φ80mm; stator end screw 8: M5; guide post nut 2: M3; end cover support rod screw 5: M10; drum left support connecting screw 16: M6; stator connection Screw 21: M6; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap