40-tonage scraper type conveyer

A technology of moving vehicles and shoveling boards, applied in the direction of lifting devices, etc., can solve problems such as poor safety, long relocation period, and high loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

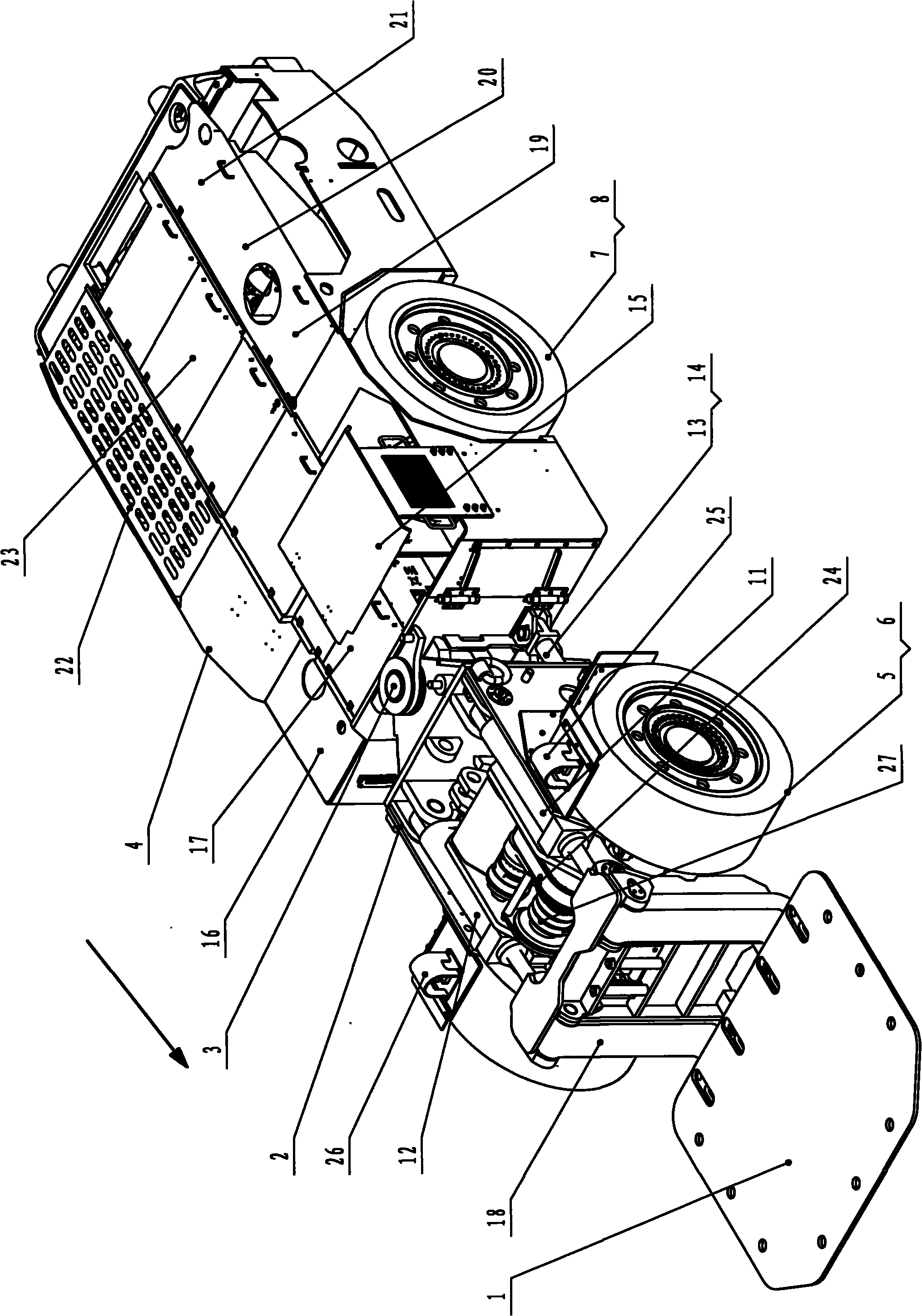

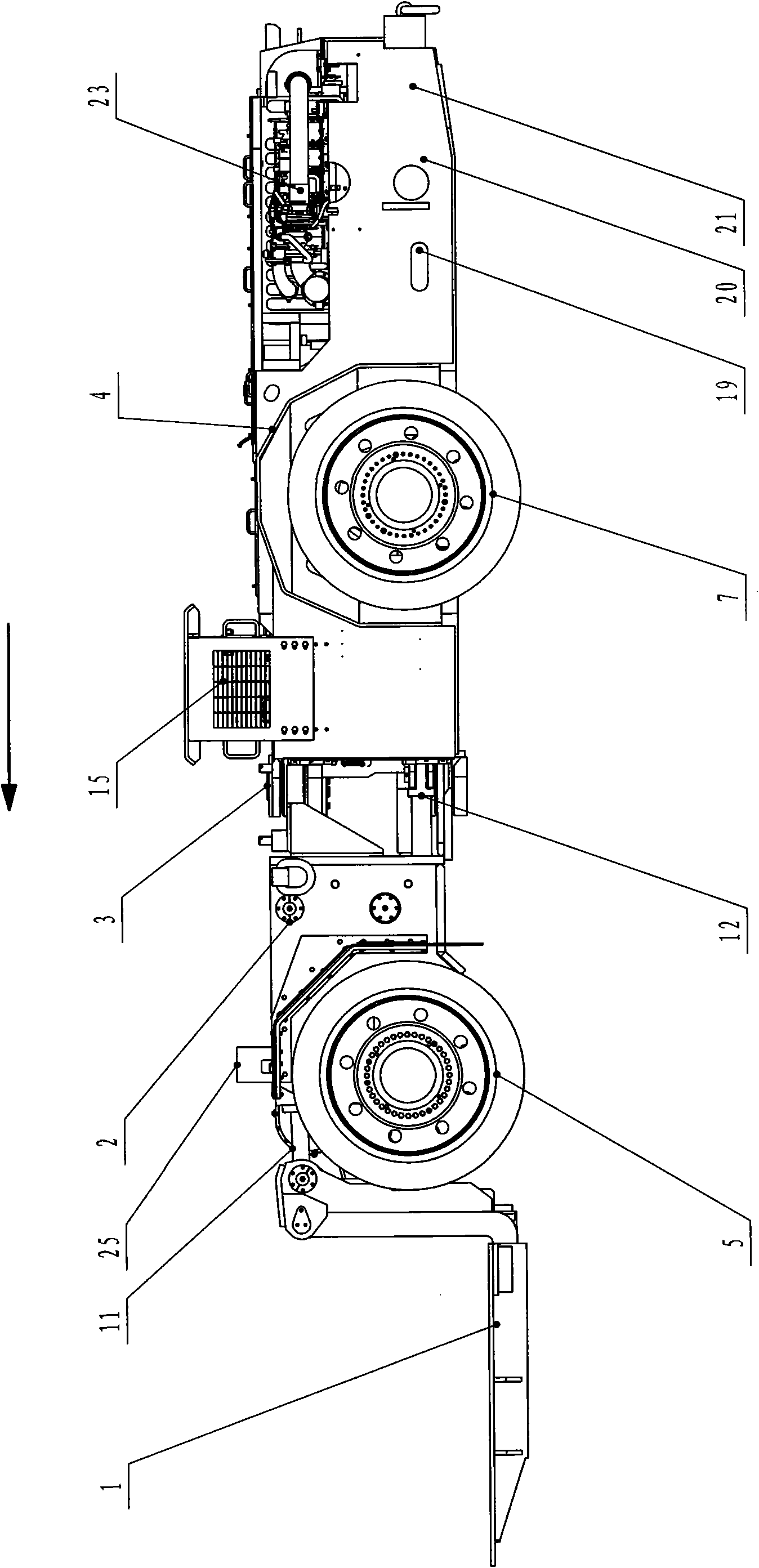

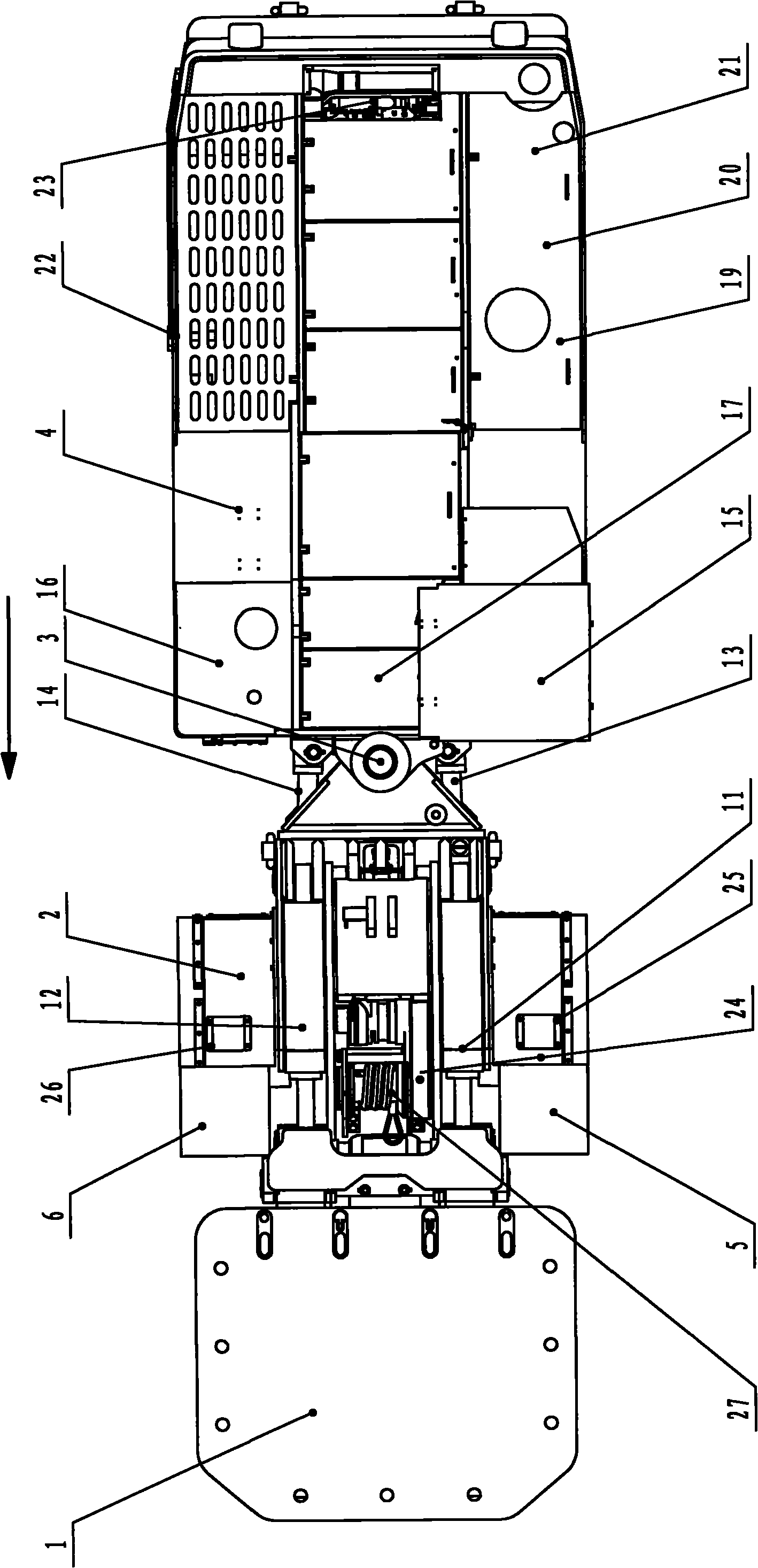

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] figure 1 , 2 , 3. Shown is the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0024] The rear part of the shovel mechanism 1 is the front frame 2, and the rear part of the front frame 2 is connected to the rear frame 4 through the central hinge frame 3;

[0025] The middle position of front frame 2 is provided with hydraulic winch 24, and hydraulic winch 24 is provided with cable 27; There are tilting oil cylinders 11, 12, left and right lifting oil cylinders 9, 10, left and right tilting oil cylinders 11, 12 are connected with forks 18, shoveling mechanism 1, and control the lifting function and tilting action of shoveling mechanism 1; The lower part of frame 2 is provided with left front wheel 5, right front wheel 6 left and right sides, and left and right front wheels 5,6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com