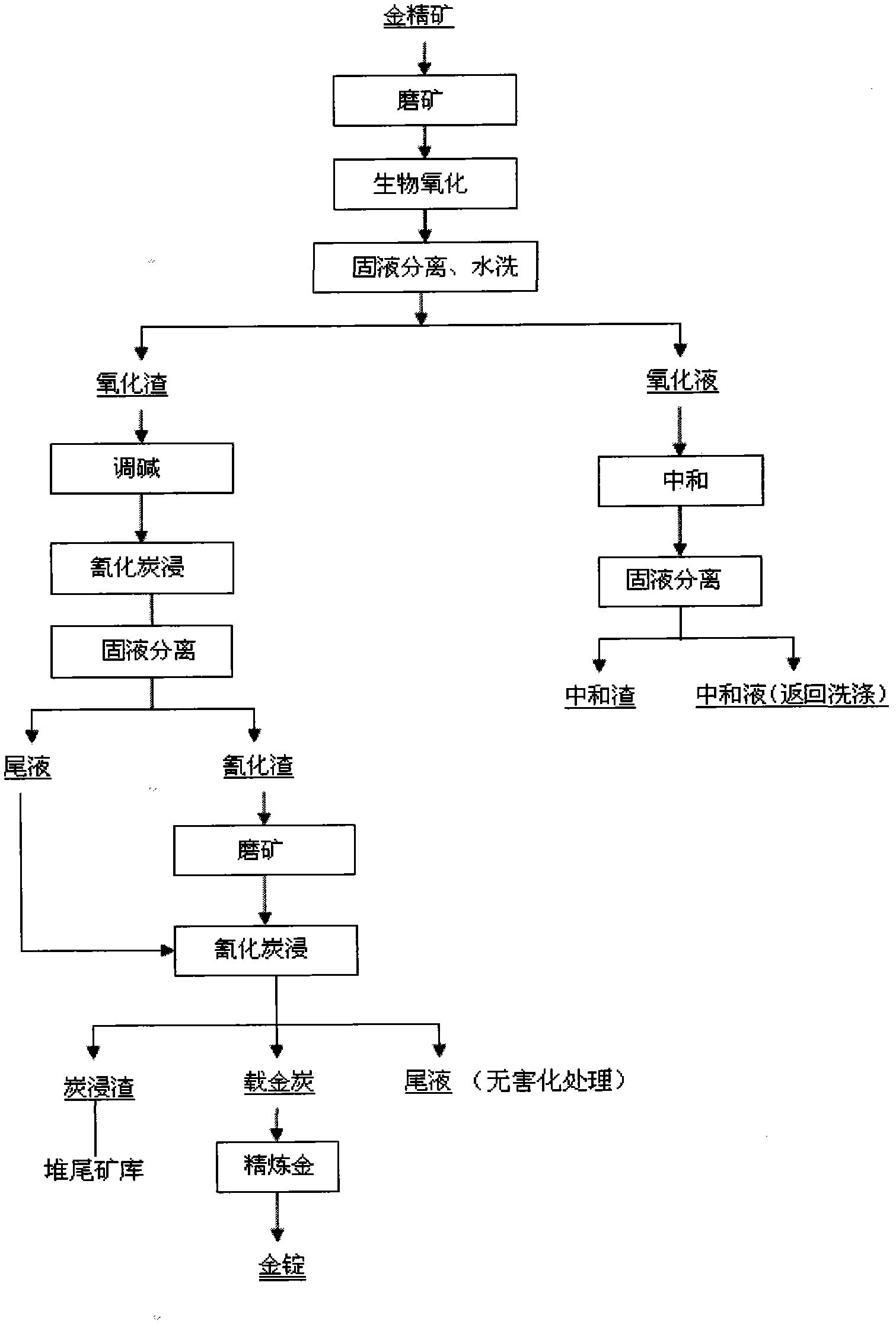

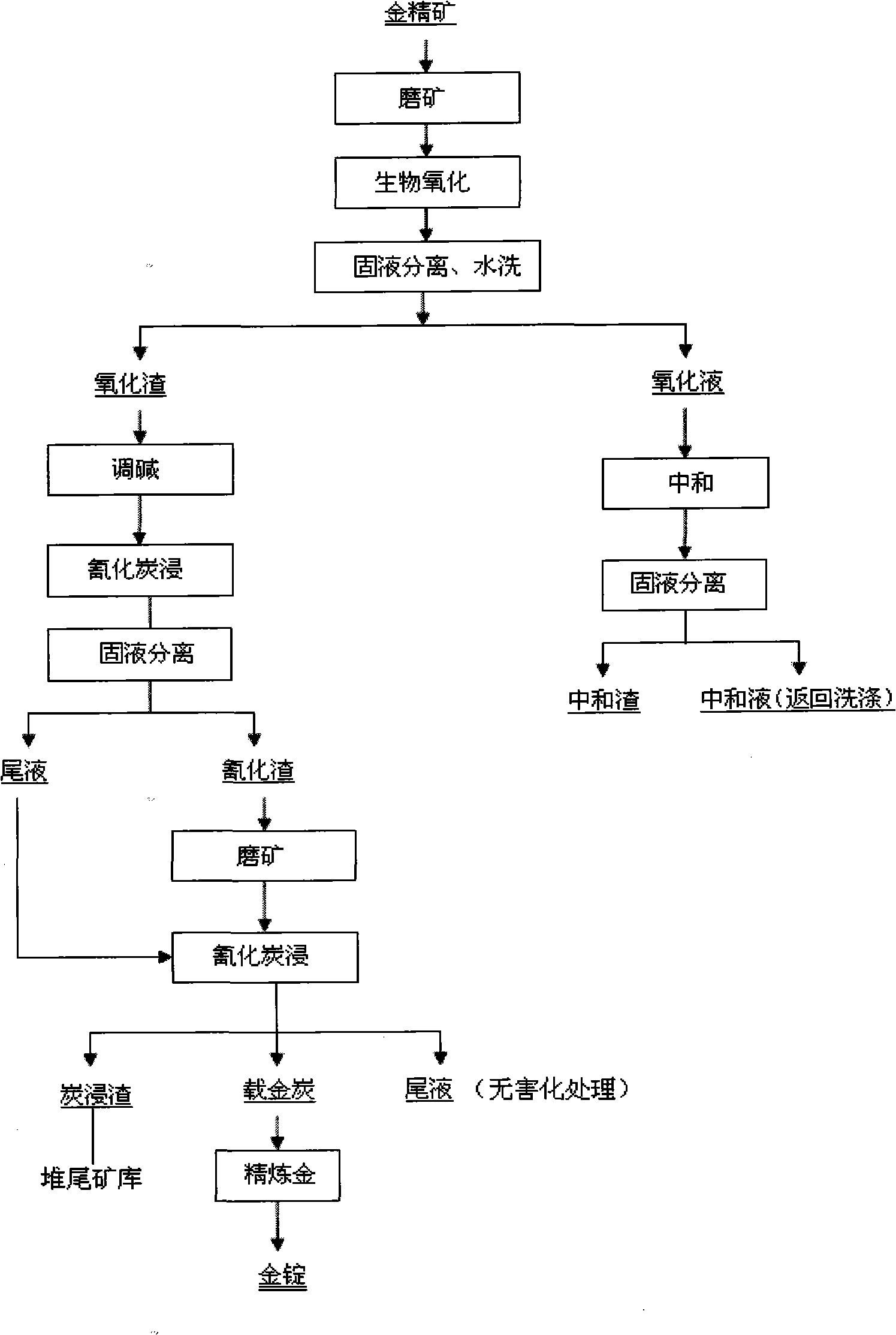

Refractory gold concentrate biological oxidizing slag cyaniding and gold-extracting method

A technology for biological oxidation and refractory gold, which is applied in the fields of cyanidation gold extraction, high arsenic and high carbon of high-sulfur refractory gold concentrate bio-oxidation slag, and can solve the problem of low gold leaching rate, low gold content in leaching slag, Problems such as high gold content, to achieve the effect of increasing the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

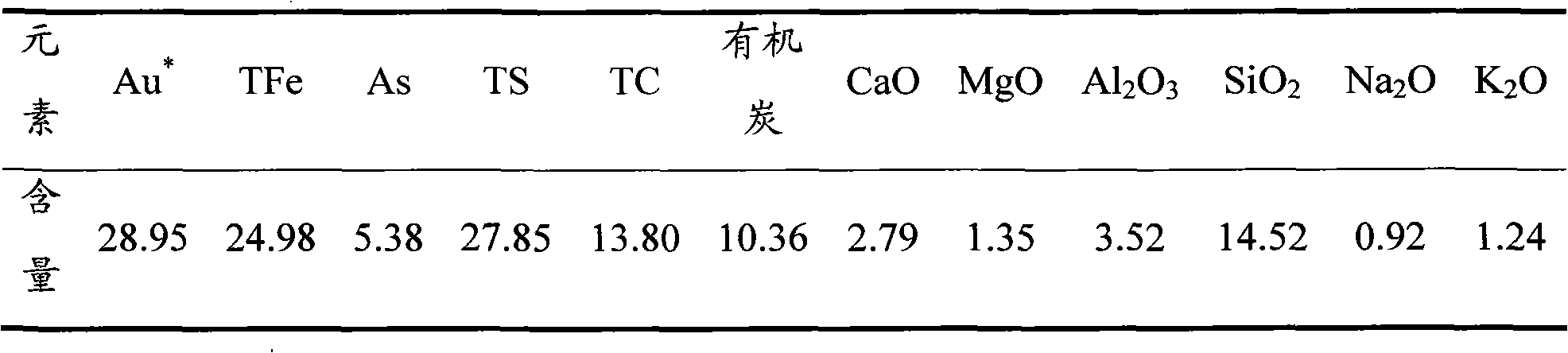

[0027] Example 1: Take 1 kg of ore, use iron-free 9K medium as nutrient substance, account for 87% of the gold concentrate particle size of -320 mesh, 18% of pulp concentration, 5 days of oxidation time, temperature of 42 ° C, initial pH of oxidation = 2.3, The dissolved oxygen amount is 1-2ppm, the linear stirring speed is 50m / min, the pH of the solution after oxidation is 0.30, and the oxidation rate of the final sulfide is 98.20%. The leaching rate of direct cyanide carbon leaching gold from oxidation residue is 82.98%. Solid-liquid separation of oxidation slag, washing with water, followed by cyanide carbon leaching, and second cyanide carbon leaching after carbon leaching slag regrinding, using a rod mill for grinding. The grinding conditions are: grinding time 1 minute, particle size -320 Mesh accounts for 90%, and the cyanide carbon leaching condition is: time 18 hours, pH=11, gac consumption 10g / L, sodium cyanide consumption 4kg / t ore, obtain final gold recovery rate 9...

example 2

[0028] Example 2: Take 1 kg of ore, and carry out a biological oxidation test according to the oxidation conditions of Example 1, and finally obtain a sulfide oxidation rate of 97.92%. The leaching rate of direct cyanide carbon leaching gold from oxidation residue is 83.26%. Solid-liquid separation of oxidation slag, washing with water, followed by a cyanide carbon leaching, and carbon leaching slag regrinding followed by a second cyanide carbon leaching, using a ball mill for grinding, the grinding conditions are: grinding time 30 minutes, particle size -200 mesh 90%, the cyanide carbon leaching conditions are: time 18 hours, pH=11, activated carbon dosage 10g / L, sodium cyanide dosage 4.5kg / t ore, the final gold recovery rate is 98.35%, and the gold leaching rate is higher than once Cyanide carbon leaching increased by 15.39%, and the concentration of sodium cyanide in the cyanide tail liquid was 85mg / L.

example 3

[0029] Example 3: Take 1kg of ore, and carry out the biological oxidation test according to the oxidation conditions of Example 1. The oxidized slag is leached while grinding by a ball mill, and the conditions for leaching while grinding are: time 24 hours, liquid-solid ratio 4: 1, pH=11 , The dosage of activated carbon is 15g / L, the dosage of sodium cyanide is 5kg / t ore, and the final gold leaching rate is 97.23%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap