Construction pushing device of steel box beam

A technology of jacking devices and steel box girders, which is applied in erecting/assembling bridges, bridge construction, bridges, etc., can solve the problems of occupying river channel structural materials, etc., and achieve the effects of good sliding ability, high durability and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

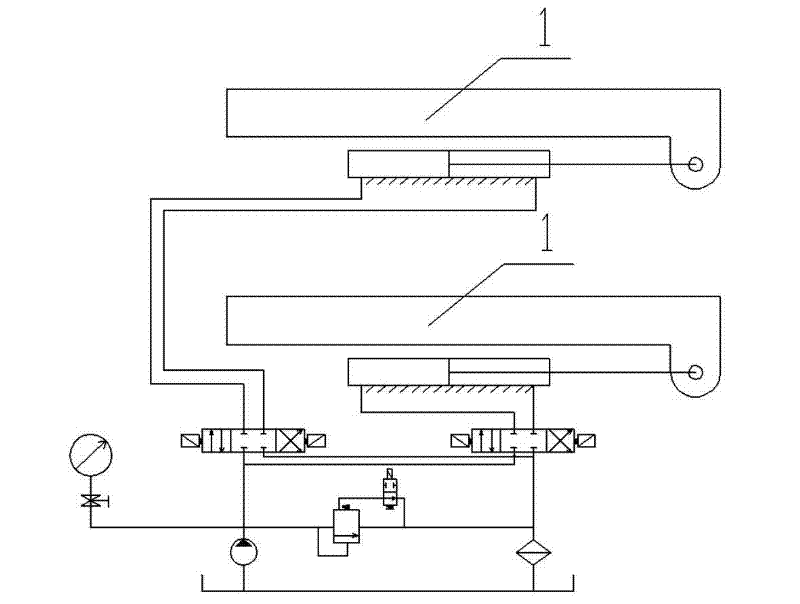

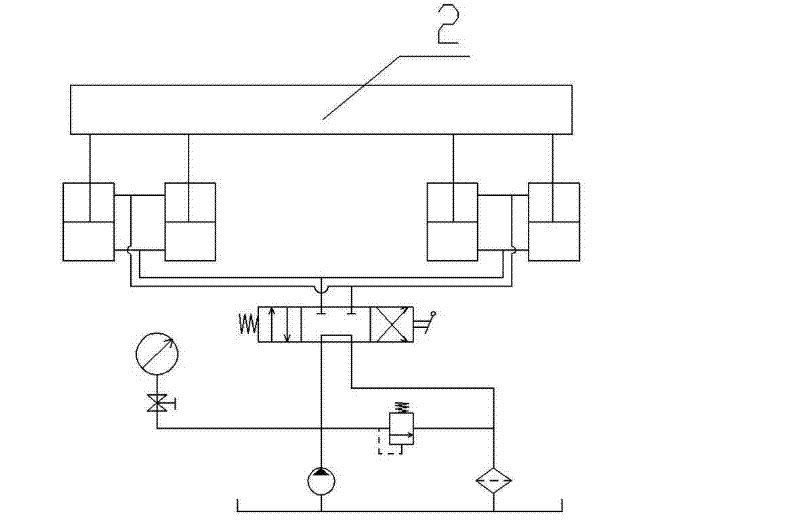

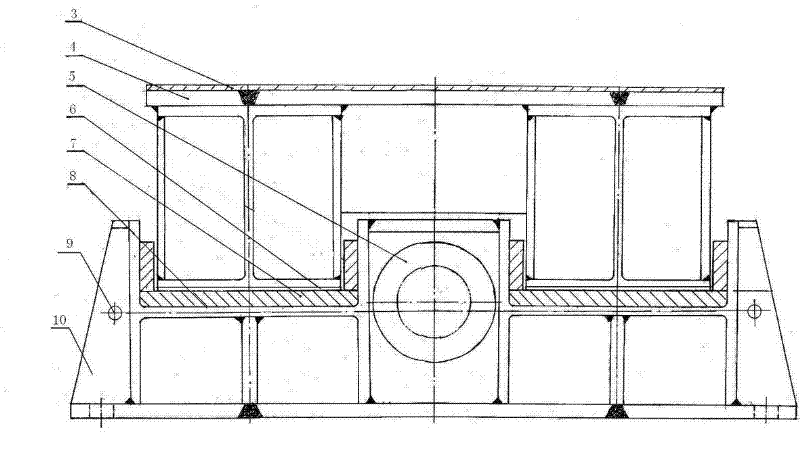

[0029] attached Figure 1-11 The marks 1-18 indicate: slide plate 1, steel box girder transverse bottom surface 2, cloth rubber plate 3, upper support plate 4, jacking force device 5, stainless steel plate 6, polytetrafluoroethylene plate 7, “U” Type slideway 8, positioning adjustment bolt 9, lower supporting plate 10, base plate 11, H-shaped steel box frame 12, pin seat 13, supporting plate 14, chute 15, rib 16, substrate plate 17, web 18.

[0030] The invention is a steel box girder erection and pushing device, which is used for vertically moving a large-tonnage steel box girder, and can complete various steel-concrete structures with large spans and continuous structures in cooperation with vertical lifting and falling beam hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com