Rotary-linear movement change mechanism and actuator

A technology of linear motion and transmission components, which is applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., can solve the problems of reduced durability, large size, and increased movement volume, and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

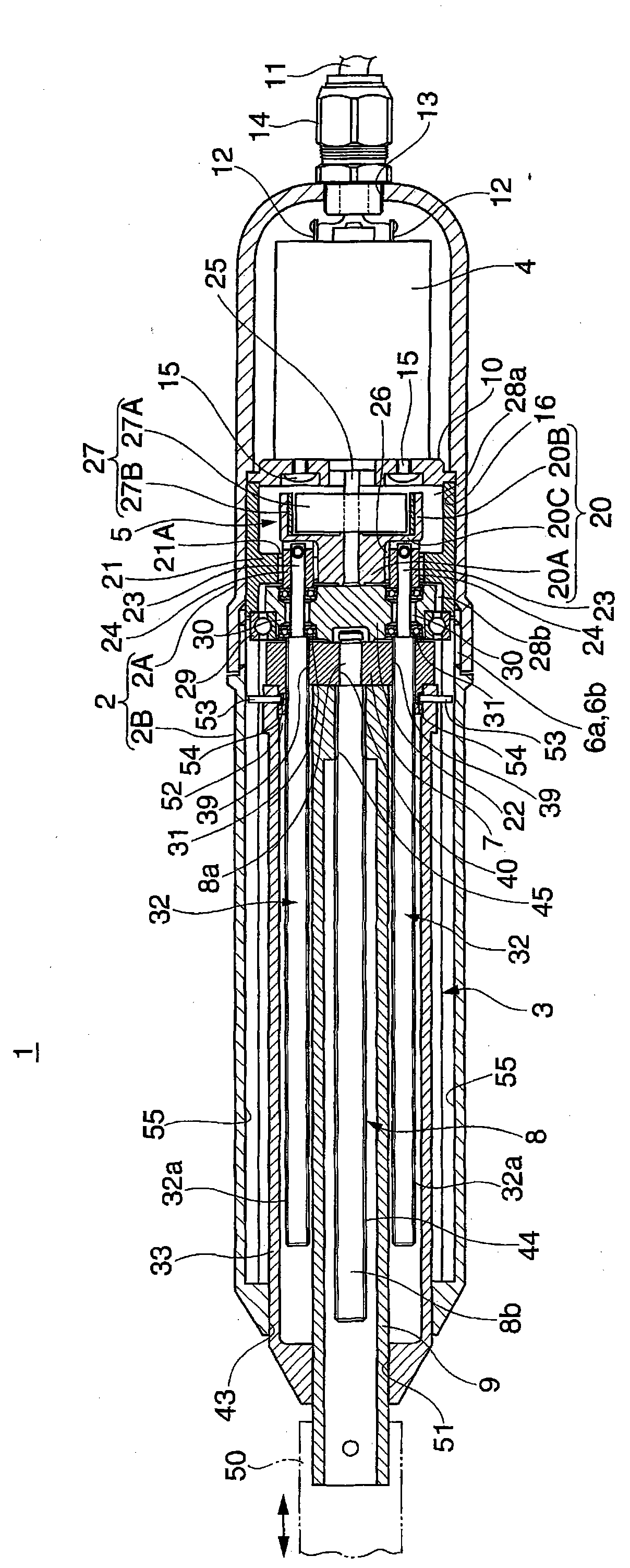

[0027] Hereinafter, the present invention will be described in detail based on embodiments shown in the drawings.

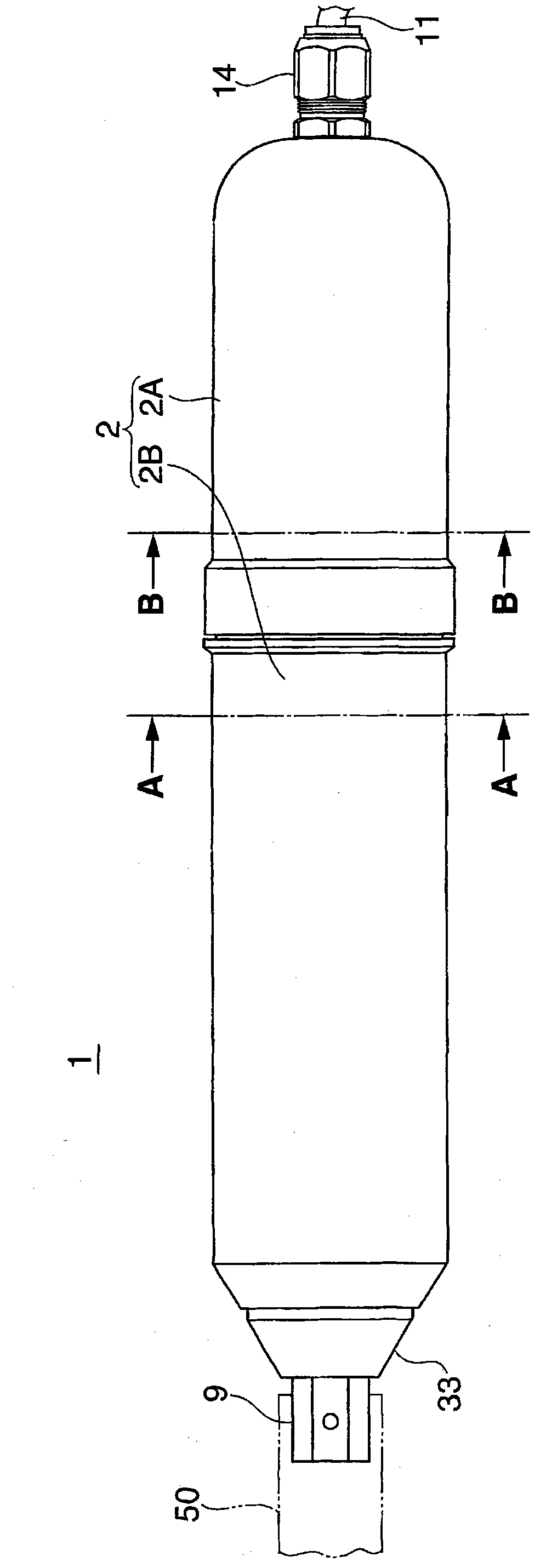

[0028] exist Figure 1 to Figure 5 Among them, this embodiment represents an actuator suitable for controlling the opening and closing of a valve. The actuator 1 includes a rotation-linear motion conversion mechanism 3 housed in a housing 2 .

[0029] The housing 2 is composed of a cylindrical housing main body 2A and a cover 2B, and the rear end side opening of the cover 2B is integrally formed with the front end side opening of the housing main body 2A by screwing the external thread 6a and the internal thread 6b. combined.

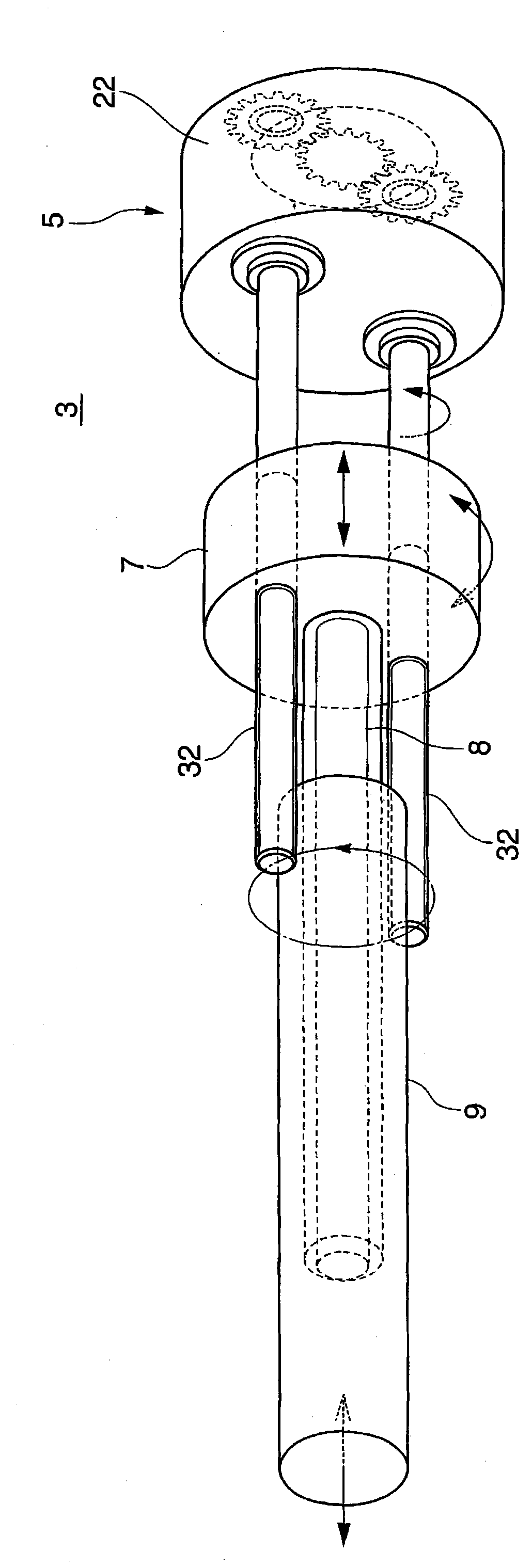

[0030] The rotation-linear motion conversion mechanism 3 includes: a motor 4 housed in the housing main body 2A, a planetary gear mechanism 5 driven by the motor 4, a transmission member 7 housed in the cover 2B, a first screw rod 8, a main shaft 9, a second Screw rod 32 and sleeve 33 etc.

[0031] The motor 4 is accommodated in the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com