Hydraulic automatic gate valve

An automatic, gate valve technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of high labor intensity, energy consumption, increase costs, etc., and achieve the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

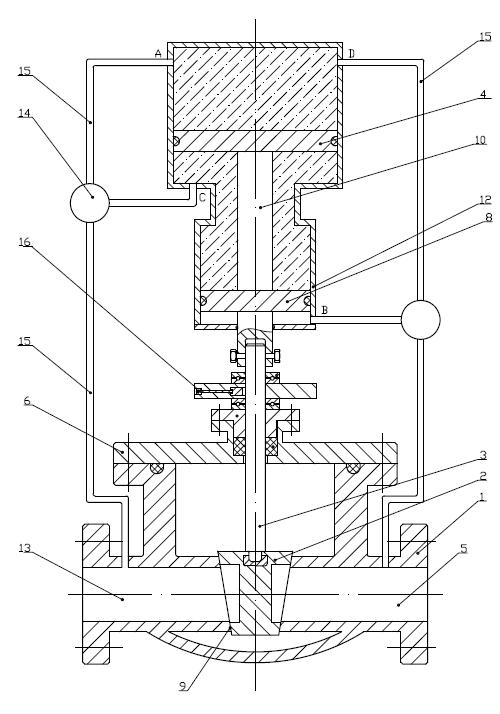

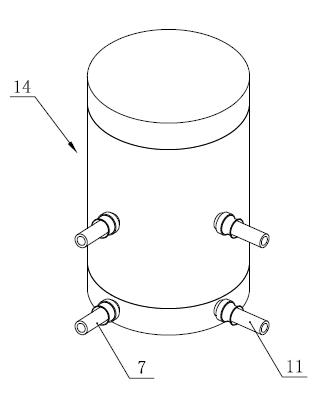

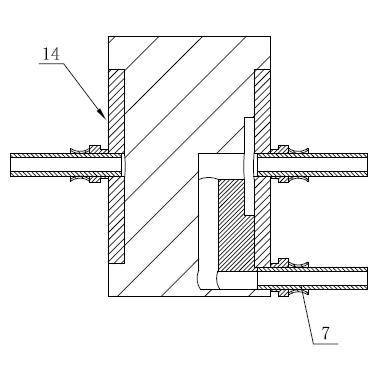

[0016] Specific embodiment 1: as figure 1 As shown in the figure, the liquid automatic gate valve still includes a valve body 1, a valve cover 6, a valve stem 3 and a gate plate 2. The inner cavity of the valve body 1 is provided with a feed channel 13 and a discharge channel 5 on both sides, and the valve cover 6 covers the valve. On the top of the valve body 1, there are valve seats 9 on both sides of the inner cavity of the valve body 1. The lower end of the valve stem 3 passes through the valve cover 6 and enters the inner cavity of the valve body 1. The gate plate 2 is fixed on the lower end of the valve stem 3 and the valve seat 17. Matching, with the upward and downward movement of the valve stem 3, the opening and closing match is formed. In order to realize the use of medium pressure as power, the liquid automatic gate valve is also provided with a valve stem driving oil cylinder 12 and a changeover switch 14 . like figure 2 , 3 As shown, the valve rod driving oil...

specific Embodiment 2

[0019] Specific embodiment 2: as Figure 7 As shown in the figure, the valve rod driving cylinder 12 in the liquid automatic gate valve can also be set upside down, that is, the valve rod driving cylinder 12 is arranged above the valve body 1, the second piston chamber is on the top, the first piston chamber is on the bottom, One end of the piston rod 10 protrudes from the bottom of the first piston cavity and is linked with the upper end of the valve rod 3. The inner cavity of the oil cylinder is divided into three parts by the first piston 4 and the second piston 8: that is, it belongs to the first piston 4 and the second piston 8. The lower part of the first piston chamber of the piston chamber (ie the part at the end of the closing direction); the upper part of the second piston chamber (ie the part at the end of the opening direction) that completely belongs to the second piston chamber and the part between the first piston 4 and the second piston 8 The portion where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com