Humidifier

A technology of humidifier and main controller, which is applied in the direction of air humidification system, heating method, lighting and heating equipment, etc. It can solve the problems of high production cost, slipping into the water tank by accident, and poor practicability, etc., and achieve practical problems, Solve the overflow problem, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

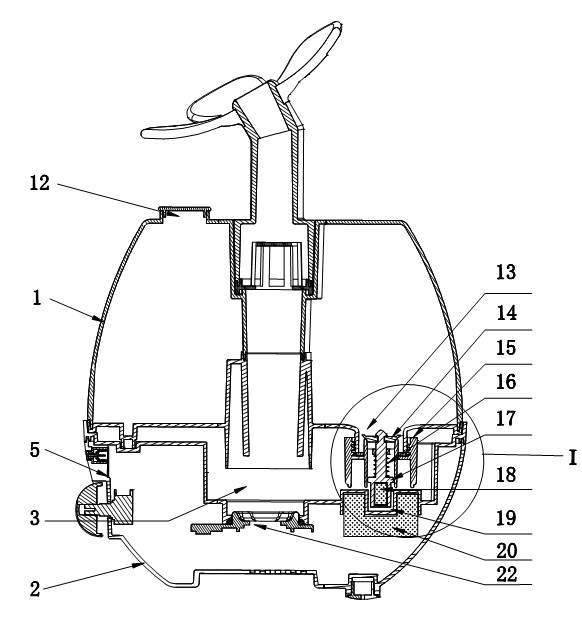

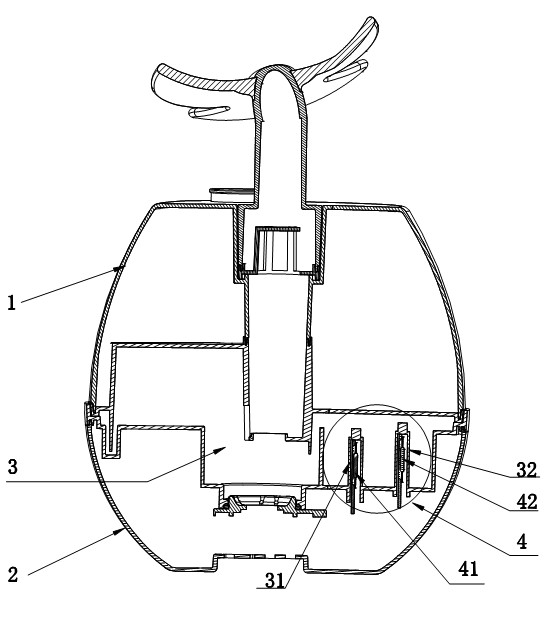

[0016] like figure 1 , 2 As shown, the humidifier of the present invention includes a water tank 1 and a base 2, wherein the water tank 1 is installed above the base 2, the bottom of the water tank 1 and the top of the base 2 form a water storage chamber 3, and the water inlet 12 of the water tank 1 Be arranged at the top, and the water outlet 13 at the bottom of the water tank 1 is provided with a launching mechanism.

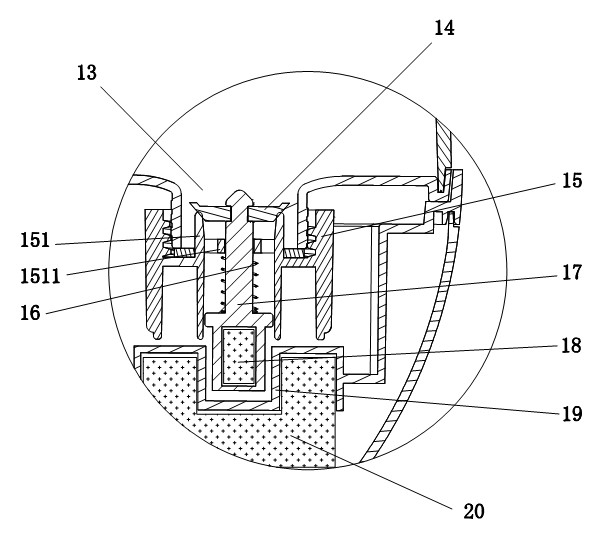

[0017] The water launching mechanism includes a water sealing cover 15, a water sealing rubber 14, a stage clip 16, a push rod 17, a magnet 18 and an electromagnet 20, wherein the main profile cross section of the water sealing cover 15 is H-shaped, and the middle plane of the H shape is H-shaped. A cylindrical sewer channel 151 of substantially equal height is provided, and a guide through hole of the ejector rod 17 is provided at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com