Online monitoring method for fouling degree of flow passage of steam turbine

A technology of flow-through part and fouling degree, applied in program control, mechanical equipment, computer control, etc., can solve the problem that data is difficult to accurately determine, and achieve the effect of automatic online monitoring, accurate judgment and scientific method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

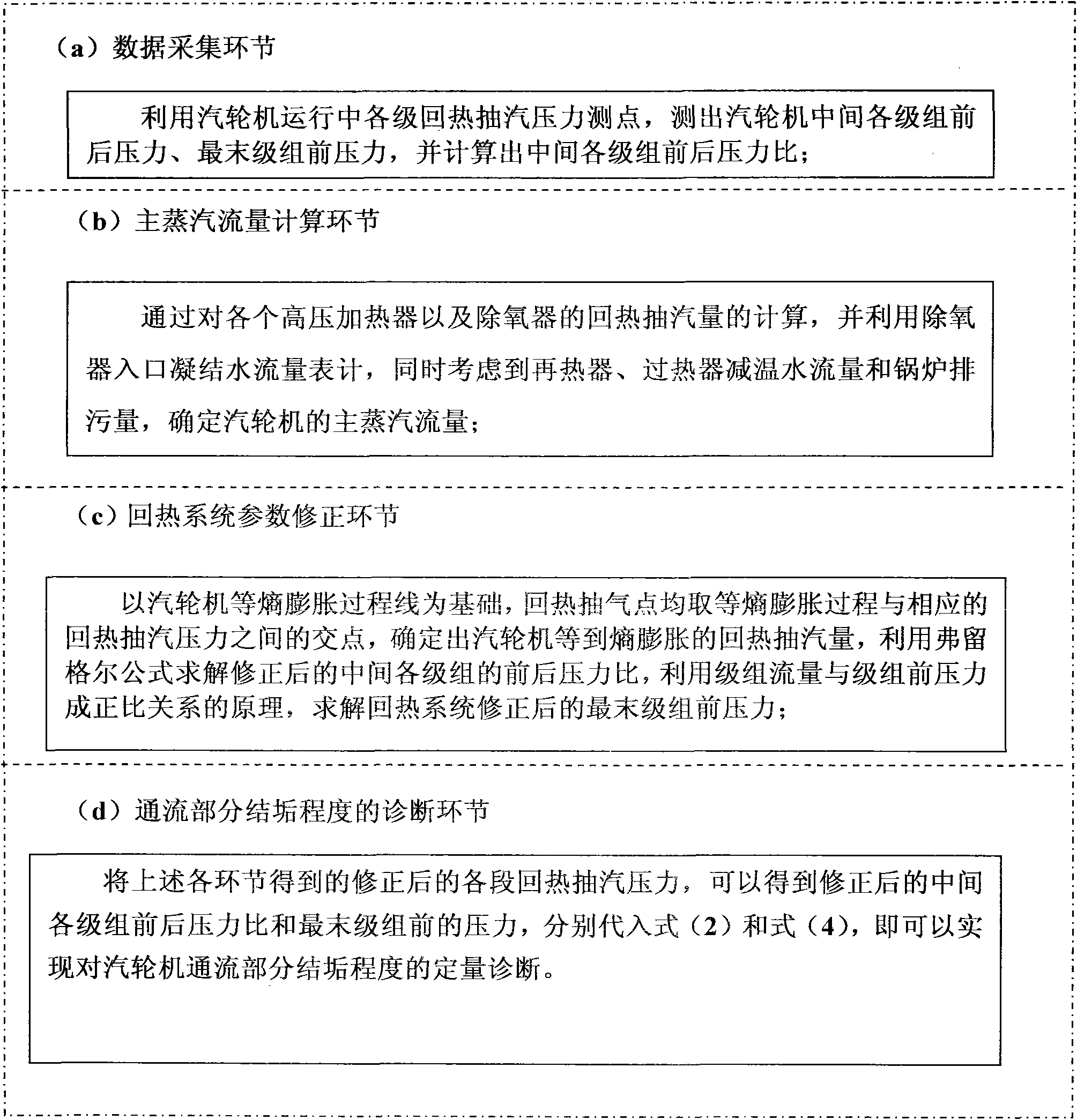

[0031] The specific implementation steps and calculation methods of the present invention will be further described below in conjunction with the accompanying drawings. Depend on figure 1 It can be seen that the method for diagnosing fouling of the flow part of the steam turbine provided by the present invention mainly consists of the following links.

[0032] 1. In the data collection link, use the pressure measuring points of the steam recovery and extraction at all levels during the operation of the steam turbine to measure the pressure before and after the middle stages of the steam turbine and the pressure before the last stage of the turbine, and calculate the pressure ratio before and after the middle stages of the group.

[0033] The present invention requires a list of monitoring parameters

[0034] Generator terminal power (KW)

Feed water pump A outlet water pressure (MPa)

Generator power factor (%)

Water temperature at outlet of feed water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com