Separable power supply plug and socket connecting structure of direct temperature-sensing type electric frying pan

A connection structure and technology for electric frying pans, applied in the fields of pancake machines and electric frying pans, can solve the problems of poor temperature control accuracy, inseparability, and low safety factor, and achieve high temperature control accuracy, convenient temperature adjustment, and temperature sensing. Numerically accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

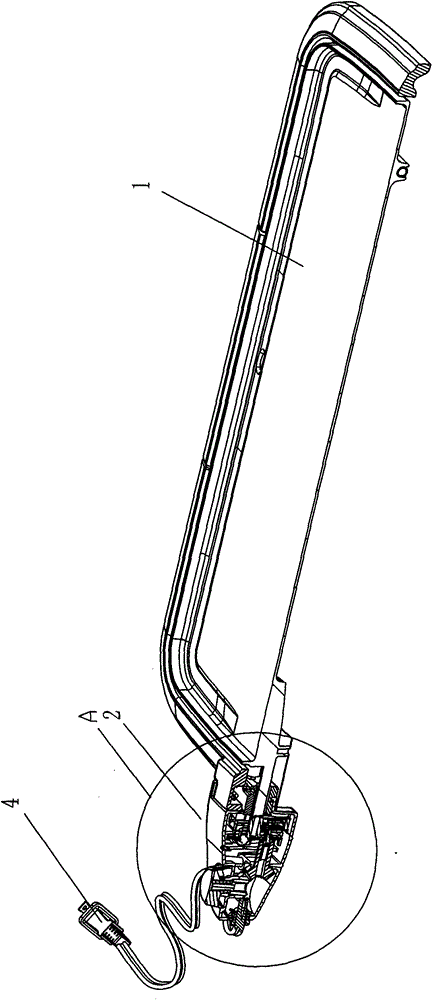

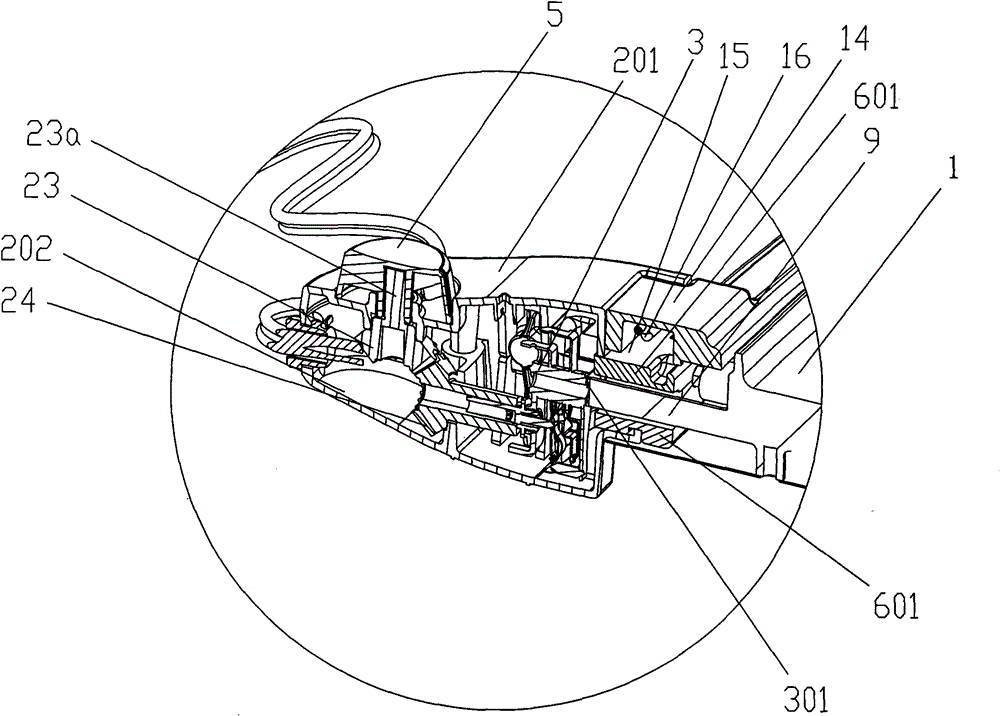

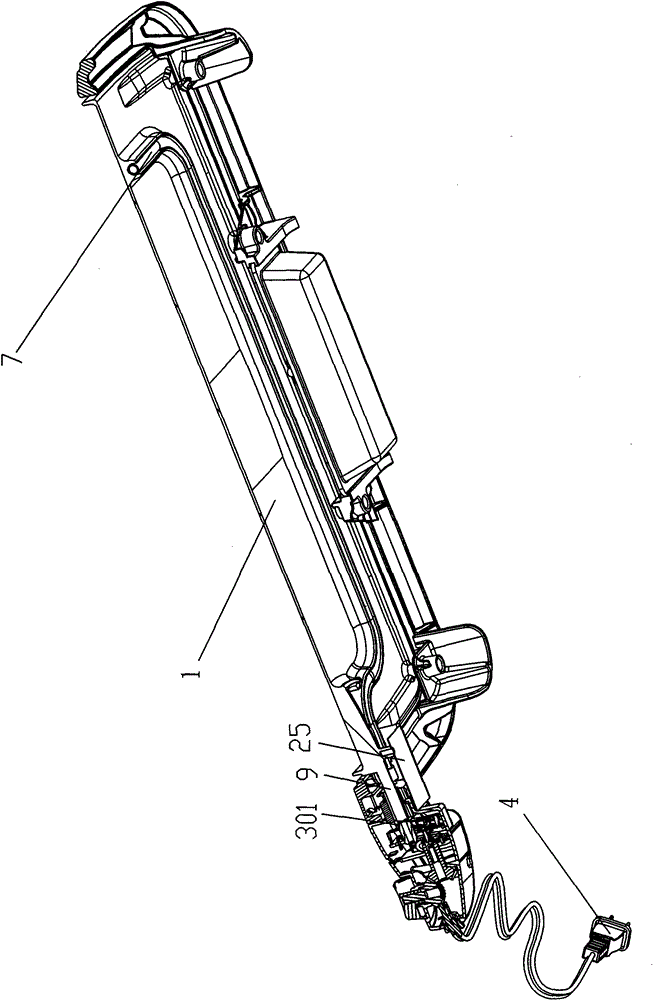

[0034] Such as Figure 1 to Figure 12Shown, a direct temperature-sensing electric frying pan detachable power supply plug connector, socket connection structure, including the pot body 1 and its movable plug control box 2, the plug control box 2 is installed with a temperature controller 3 , the plug control box 2 is connected with an external power input plug 4, the external power input plug 4 is electrically connected with the temperature controller 3, the plug control box 2 is provided with a temperature control knob 5, and the front end of the plug control box 2 is installed There is a socket 6 with a plug-in hole 12, and the heating element 7 at the bottom of the pot body 1 extends a plug 8 that can be plugged and matched with the plug-in hole 12, and the socket 6 corresponding to the thermostat 3 is opened. There is a heat transfer socket 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com