Novel embedded junction box

A junction box, pre-embedded technology, applied in electrical components and other directions, can solve the problems of wasting materials, contractor losses, line breakage, etc., to increase construction quality, facilitate construction, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

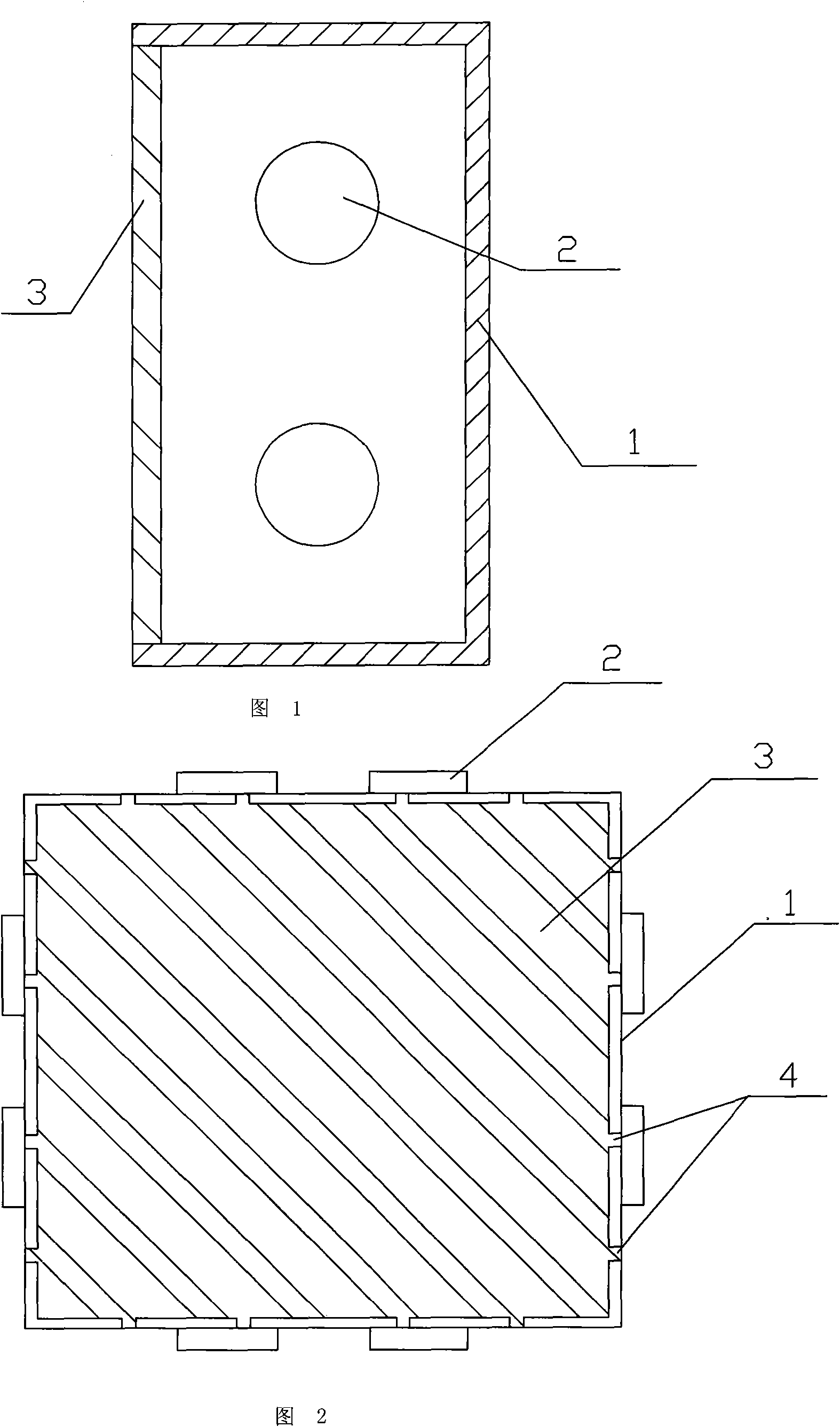

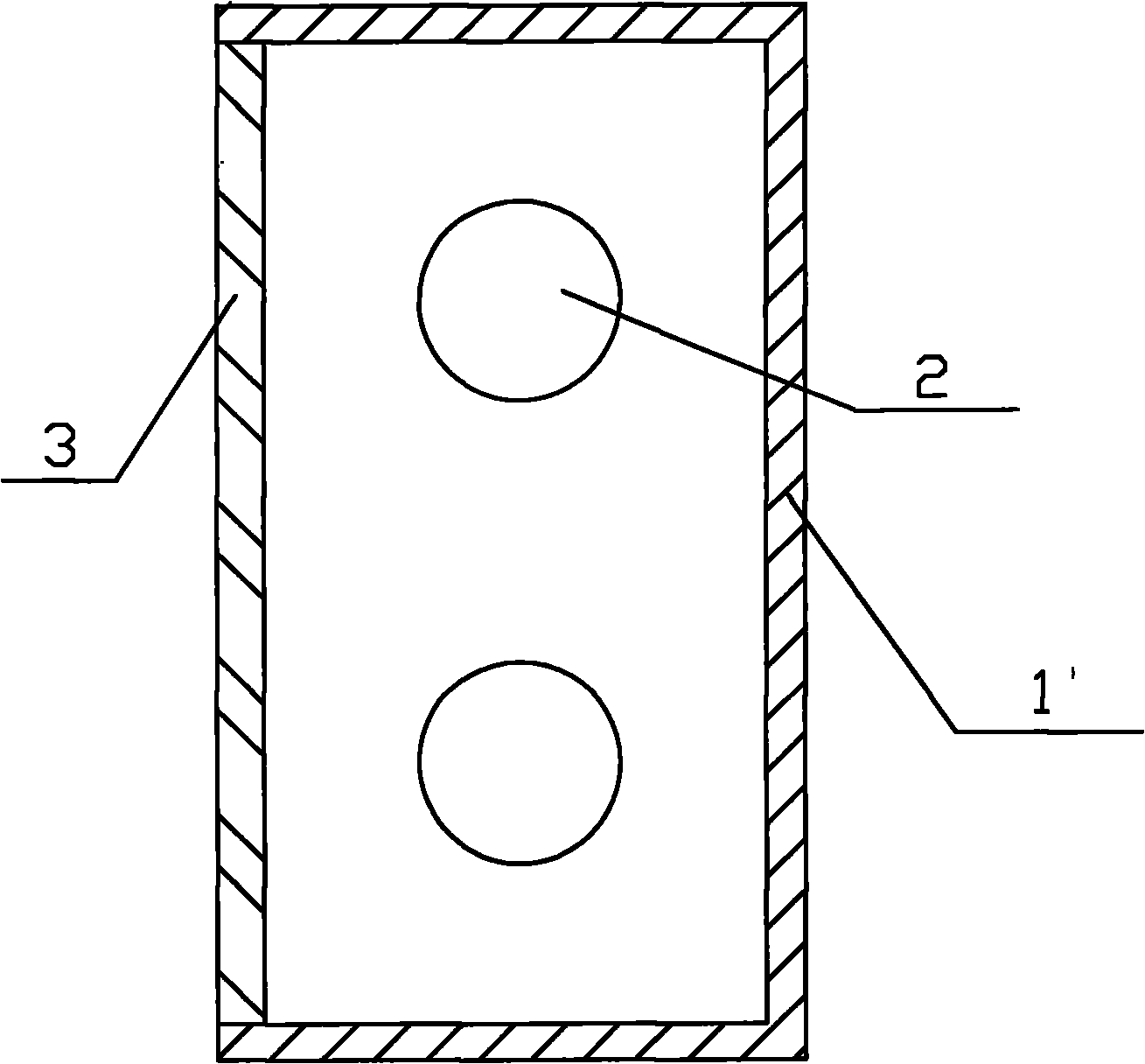

[0010] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it is composed of a box body 1, a threading hole 2, a baffle plate 3, and a connecting block 4. The threading holes 2 are uniformly arranged around the box body 1 , and the baffle plate 3 is fixedly connected with the box body 1 through the connecting block 4 . After the demolition of the civil construction is completed, it is only necessary to break the baffle plate 3 by means of external force to carry out threading construction.

[0011] The connection block 4 in this specific embodiment is cast together with the box body 1 during casting.

[0012] The advantage of this specific embodiment is that it can effectively solve the problem of concrete pouring back in the background technology, greatly facilitates the construction of pre-embedded line pipes, saves a lot of labor, and increases the construction quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com