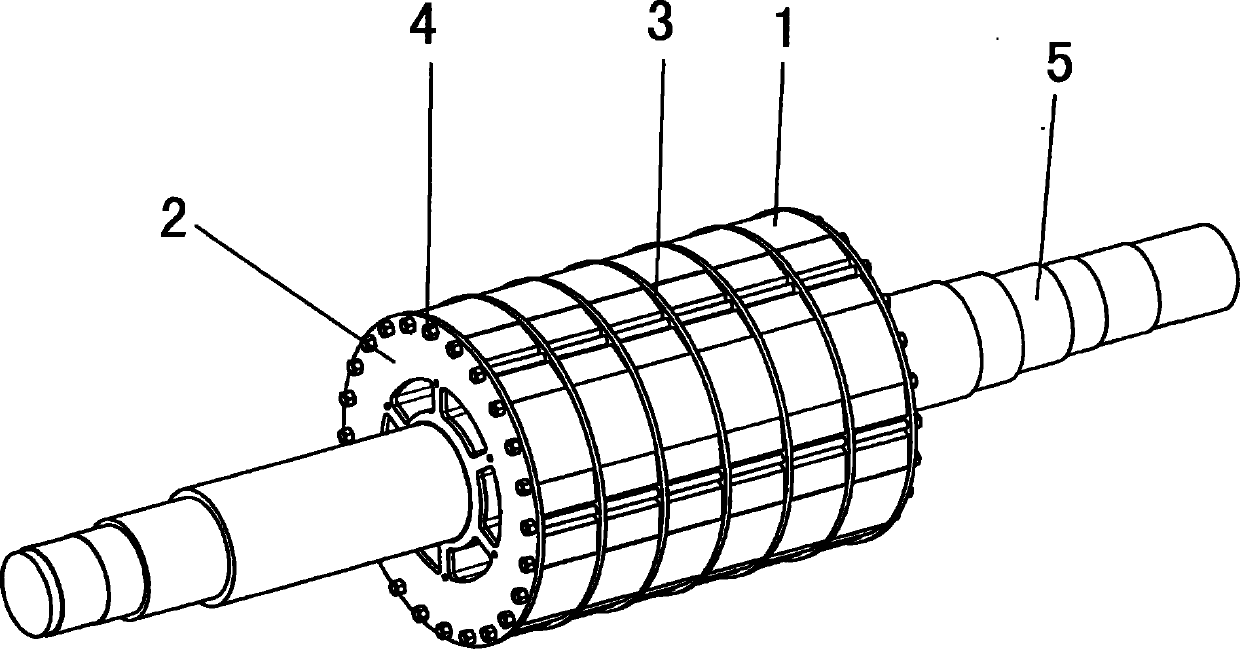

High-power permanent-magnet motor rotor, installation method of rotor and method for magnetizing rotor permanent magnet

A permanent magnet motor, high-power technology, used in the manufacture of stator/rotor bodies, magnetic circuit rotating parts, wind power generation, etc., can solve the problems of easy generation of magnetic leakage flux, difficult installation of permanent magnets, and inconvenient rotor assembly. Achieve the effect of reducing harmonic content, improving utilization, and simplifying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

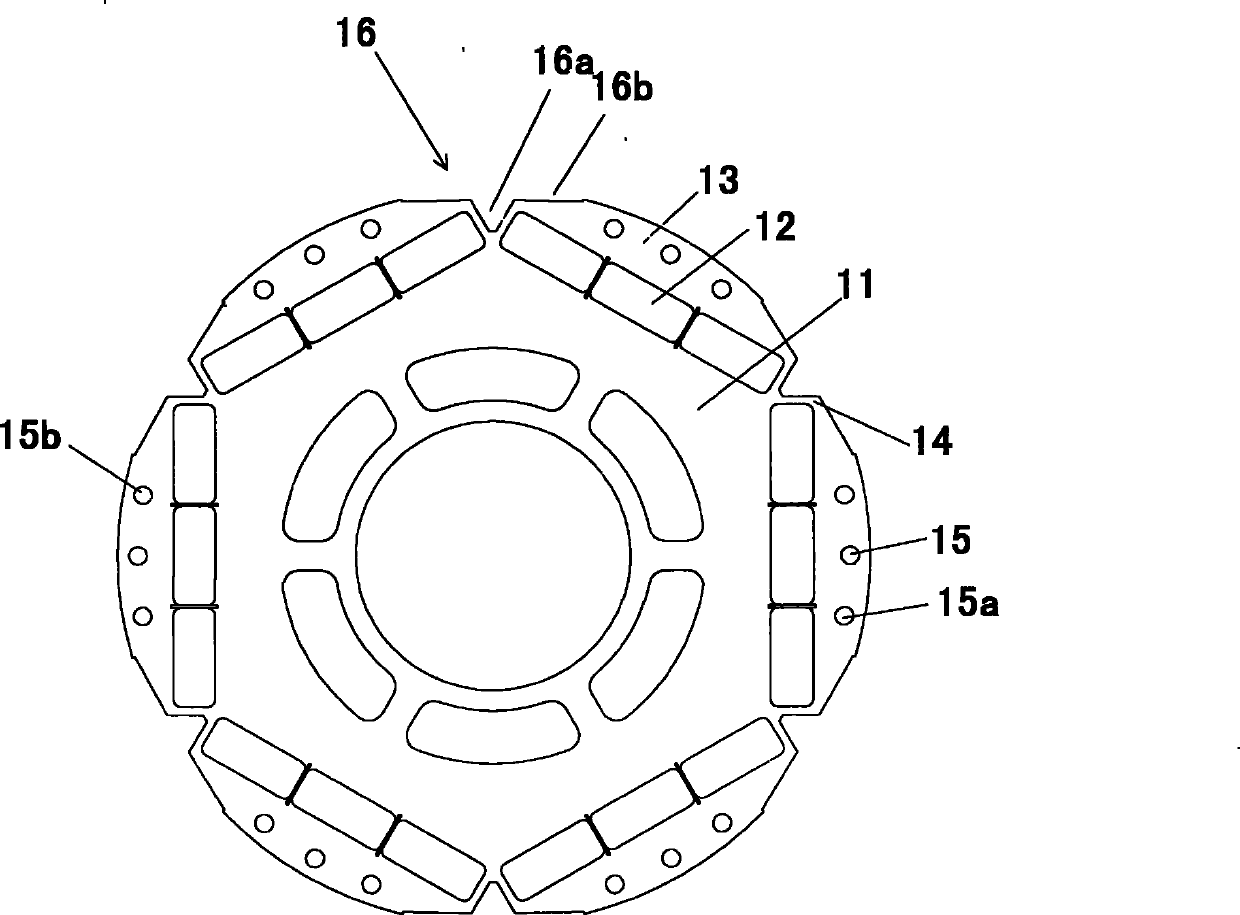

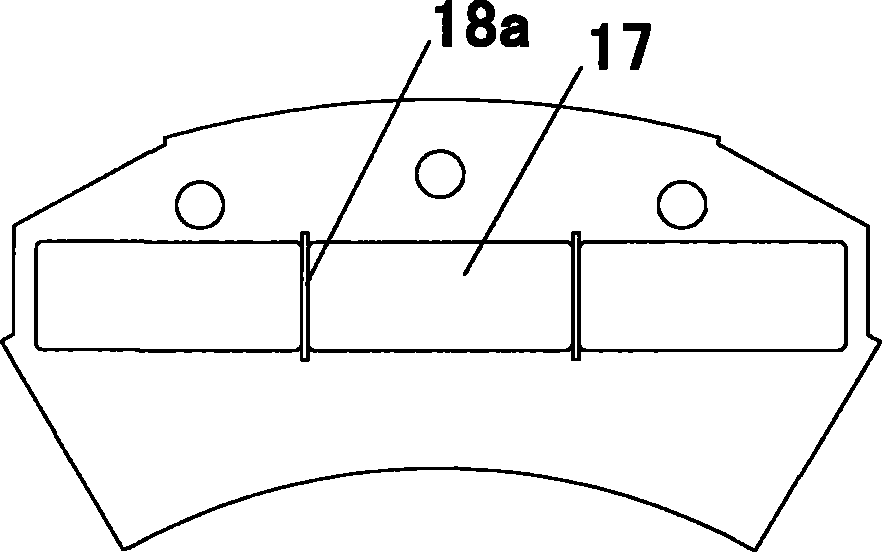

[0035] The gist of the present invention is to provide a high-power permanent magnet motor rotor, especially a rotor used on a high-power permanent magnet synchronous generator, as well as an assembly method of the rotor and a magnetization method of the rotor permanent magnet, so as to solve the problem of For embedded high-power permanent magnet synchronous generators, the permanent magnet magnetic field between adjacent two poles of the rotor is easy to be directly connected, which will cause magnetic flux leakage, resulting in low utilization of permanent magnet materials; during the rotation of the rotor, the rotor permanent magnet and The rotor pole shoes are subjected to centrifugal force in the relative direction of rotation, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com