Machine tool having an electric drive motor

A technology for electric drive motors and machine tools, which is applied in the direction of manufacturing tools, portable motorized devices, metal processing equipment, etc., can solve the problems of reducing heat discharge, function failure, and pollution of drive motor machine tool parts, and achieves improved flow guidance and less The effect of losing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

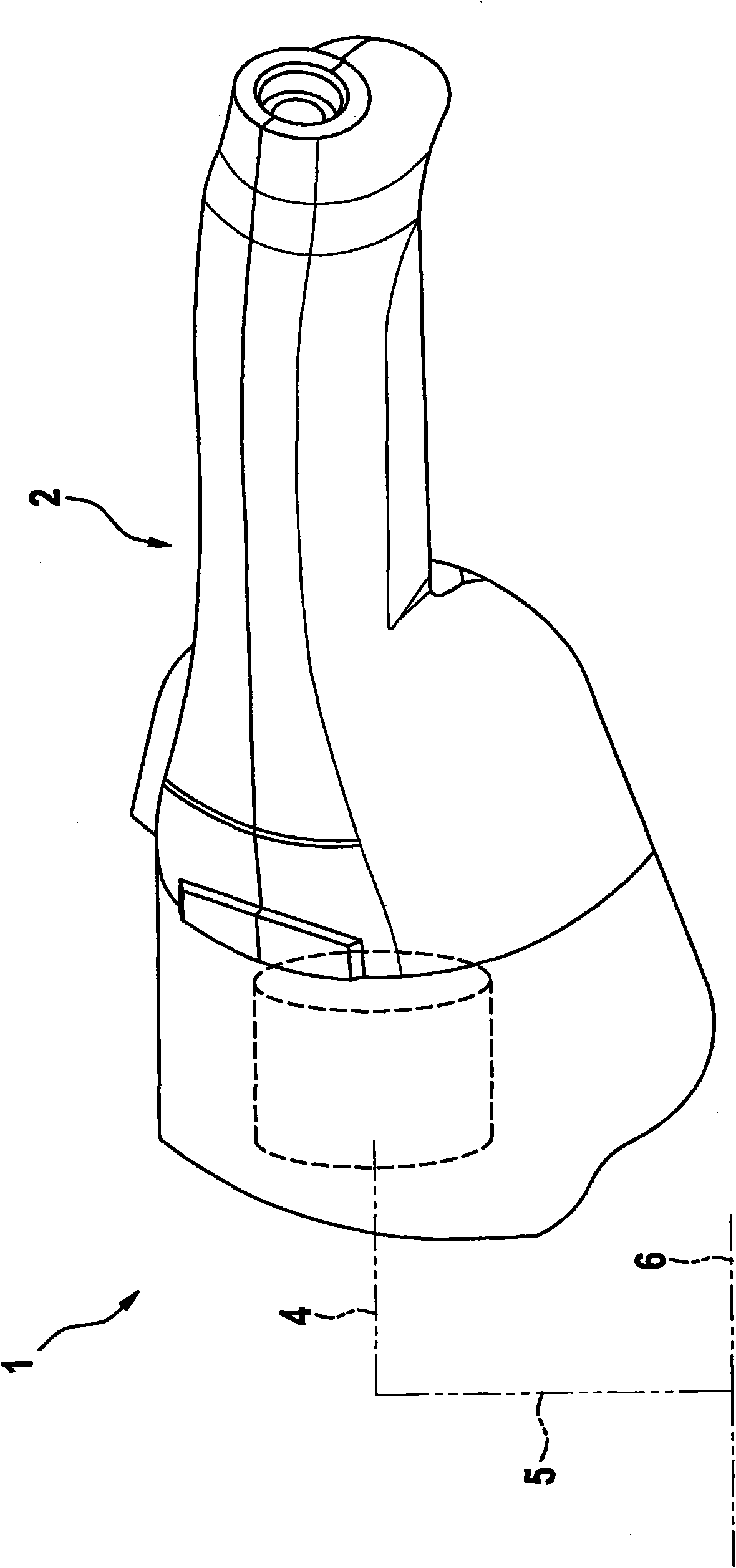

[0020] figure 1 The hand-held power tool 1 shown in a general manner has an electric drive motor 3 in a housing 2, which is designed as an AC motor, preferably as a series motor, wherein a DC motor is also conceivable if necessary . The rotor shaft or armature shaft 4 of the drive motor is rotationally coupled to and drives a tool shaft 5 mounted rotatably in the housing, on which a tool 6 for machining a workpiece is fastened.

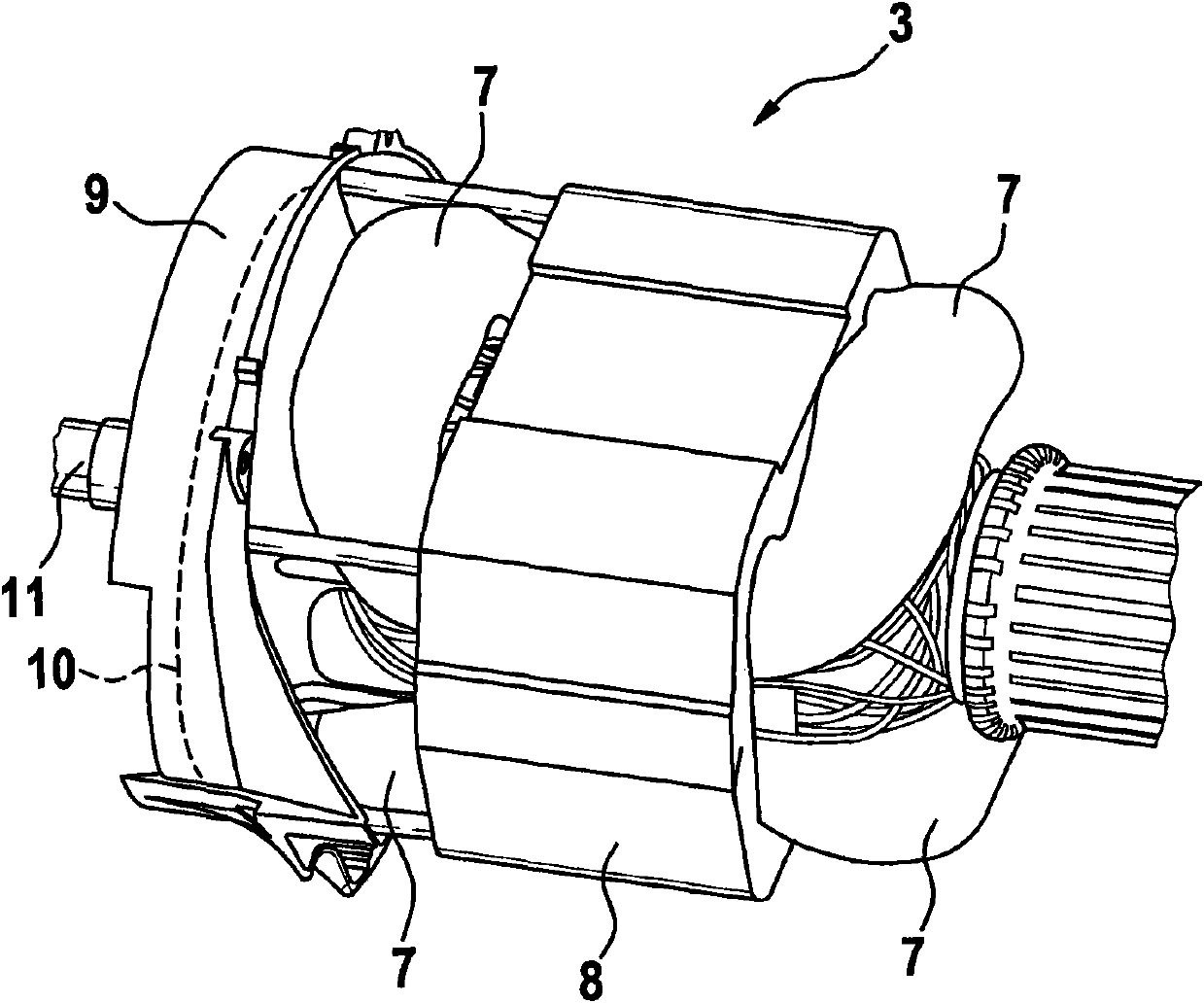

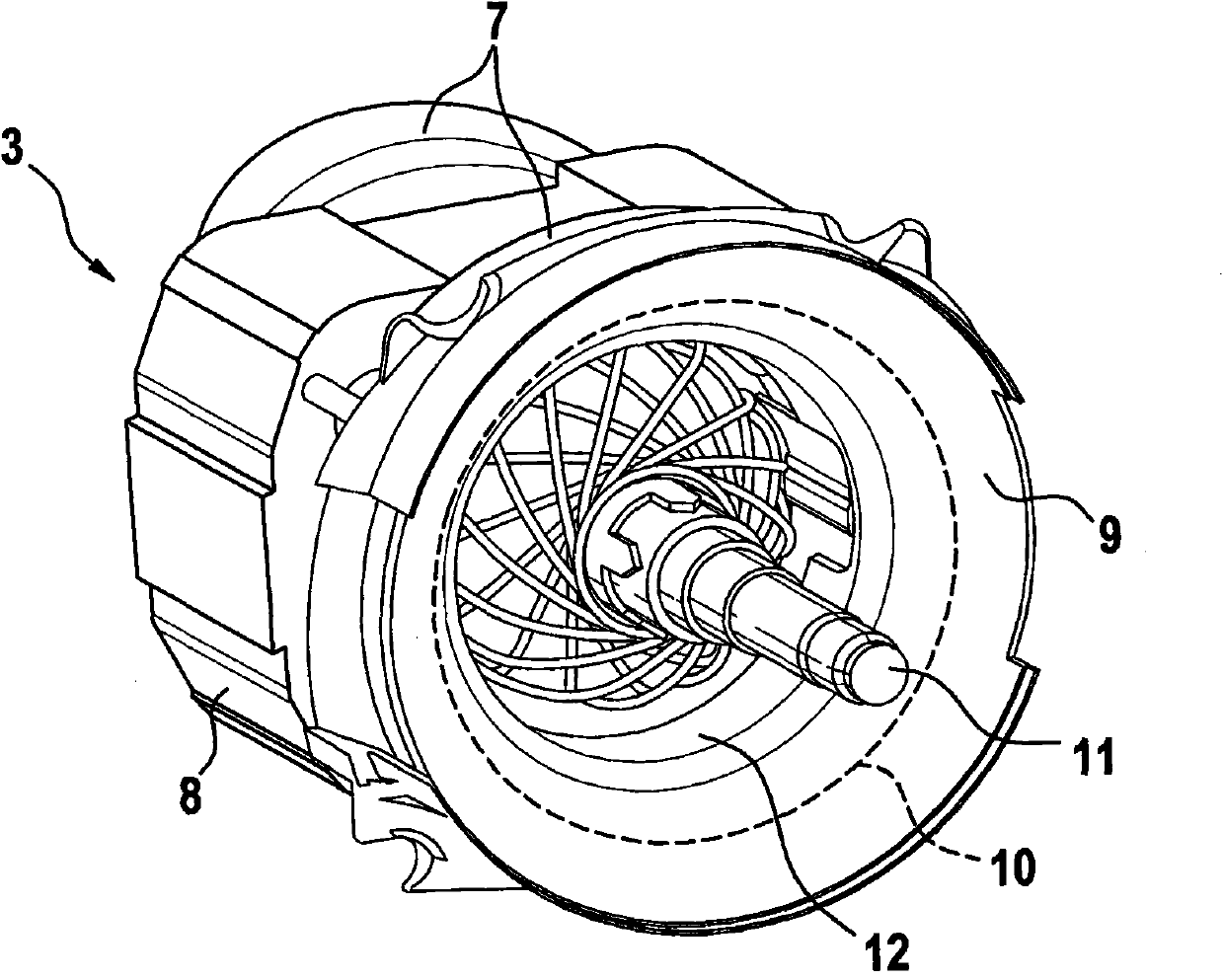

[0021] From figure 2 and 3 It can be seen from the figure that the electric drive motor 3 has a pole shoe 7 which is designed in particular as a winding end and forms part of the stator of the drive motor. Furthermore, there is a grounding part 8 which surrounds the pole piece 7 in a ring, which can optionally also have permanent magnets.

[0022] On one end side of the electric drive motor 3 is arranged coaxially to the rotor shaft or armature shaft 11 of the drive motor an air guide ring 9 in which a fan impeller, shown only schematically, can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com