Method and apparatus for pneumatically forming mixture in premix burner and inlet forestage for burner

A technology of burners and mixtures, applied in the field of aerodynamically forming stable mixtures, devices, and situations, which can solve problems such as insufficient burners and system shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

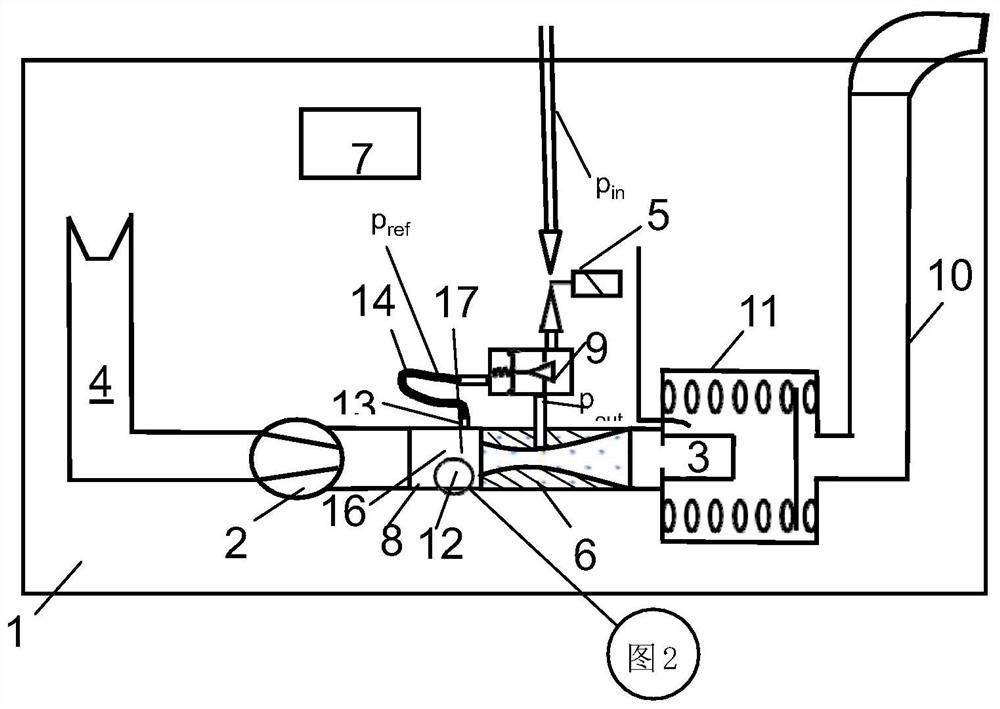

[0018] figure 1 The device according to the invention, namely the heating device 1 , is shown schematically with details which are crucial for understanding the invention. The blower 2 sucks in ambient air via an air suction duct 4 and delivers it to the burner 3 . Behind the blower 2 and in front of the burner 3 , the air flows through a throttle 6 , in particular in the form of a Venturi nozzle, in which the combustion gas is mixed with the air flow. The combustion gas passes from the supply line via the combustion gas shut-off valve 5 to the combustion gas regulating valve 9 at the supply pressure Pin and from there to the throttle point 6 at the outlet pressure Pout. The combustion gas regulating valve 9 is connected to a reference pressure measuring point 13 via a control line 14 . The reference pressure Pref obtained there determines whether and to what extent the combustion gas control valve 9 is opened in order to mix a quantity of combustion gas corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com