Forging process for producing mushroom-shaped flange on die forging hammer

A mushroom-shaped, die-forging hammer technology, applied in the field of forging technology, can solve the problems of full flange shaft, increased production cost, and difficult to achieve, and achieves the effect of increasing flow speed, ensuring fullness, and facilitating fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

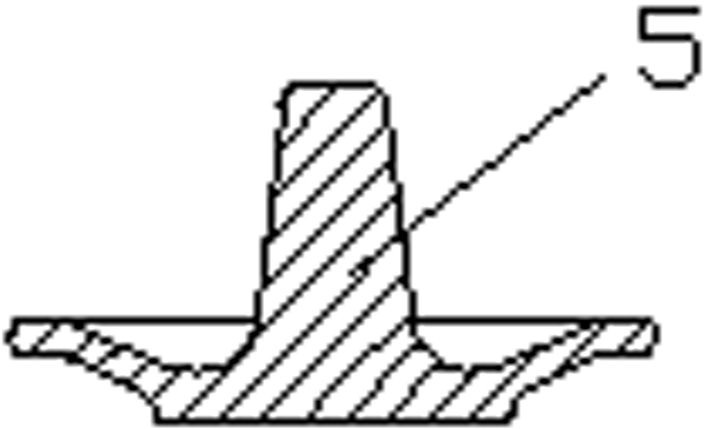

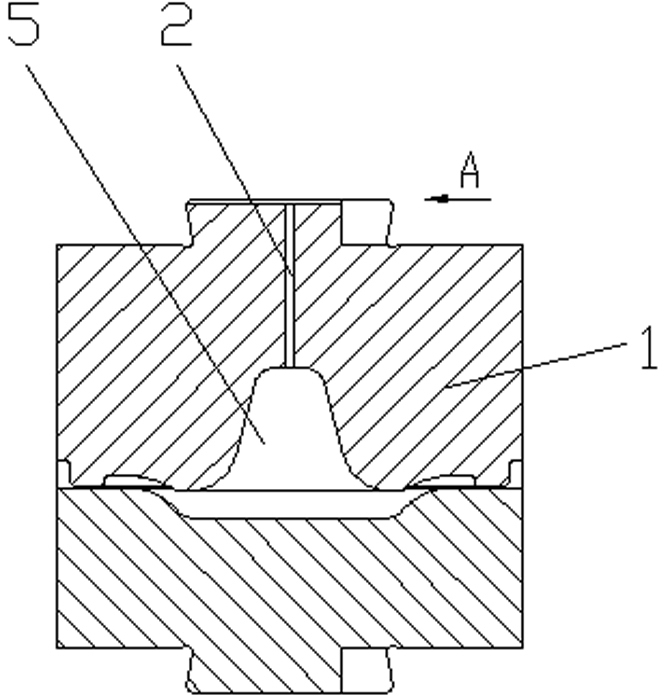

[0015] see Figure 2 to Figure 5 , a forging process for producing mushroom-shaped flanges on a die forging hammer. There is a valve at the center of the shaft of the mushroom-shaped flange corresponding to the pre-forging die chamber and the final forging die chamber to make the water vapor and air at the bottom of the die chamber timely The discharged vent hole 2, based on the function of the vent hole 2, is provided on the forging die corresponding to the center of the flange shaft. The diameter of the vent hole 2 directly affects the filling degree of the flange shaft end: if If the diameter of the vent hole 2 is large, the metal flow will be fast, and the filling degree of the shaft end will be better, but an obvious boss may be formed on the shaft end of the flange, which will affect the quality of the end face; if the diameter of the vent hole 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com