Cassette transport apparatus

A technology for conveying devices and cassettes, which is applied to storage devices, transportation and packaging, electrical components, etc., can solve the problems of reduced cleanliness in the internal space of cassettes, and achieve the effect of simple structure, large size and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

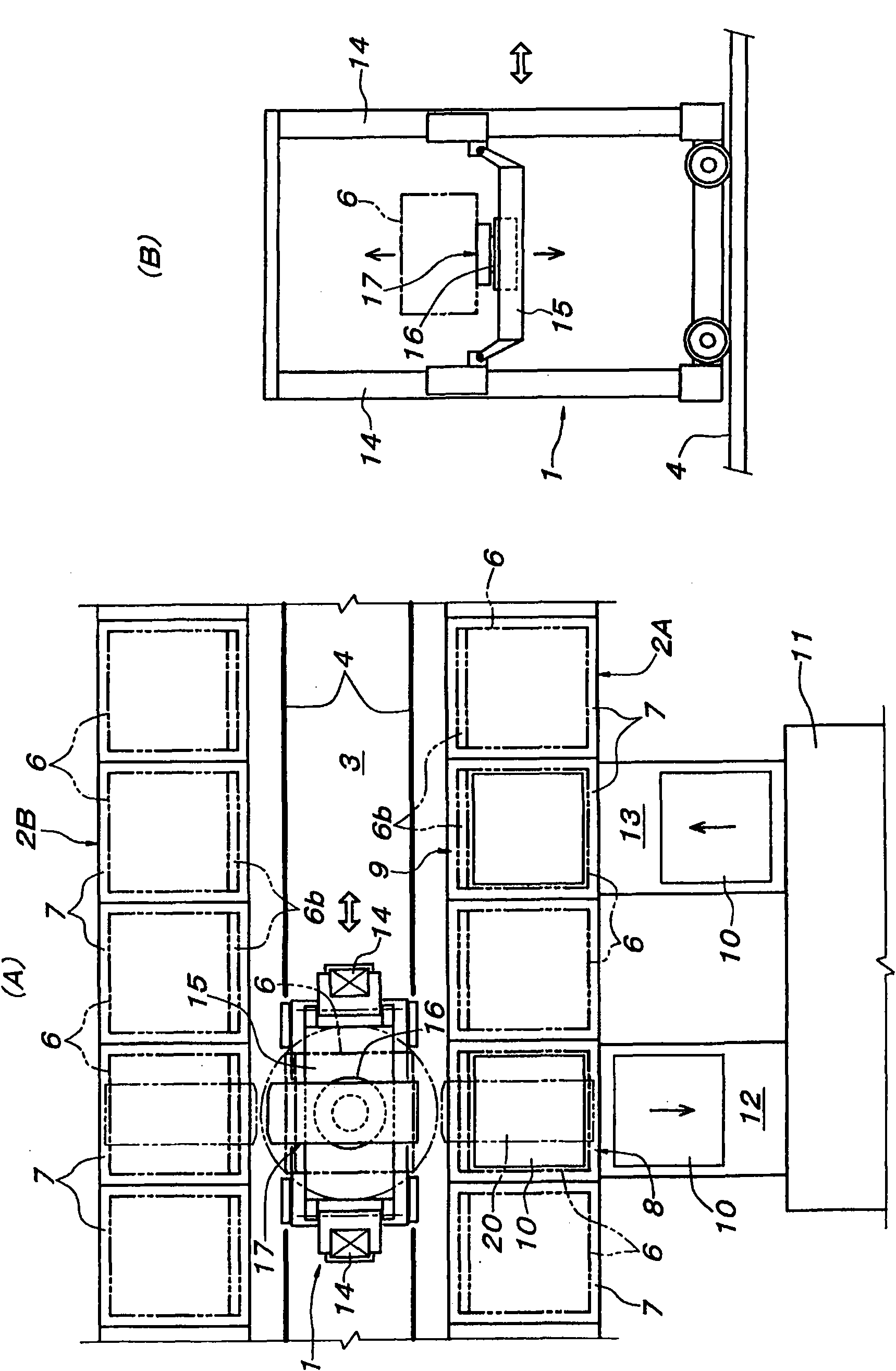

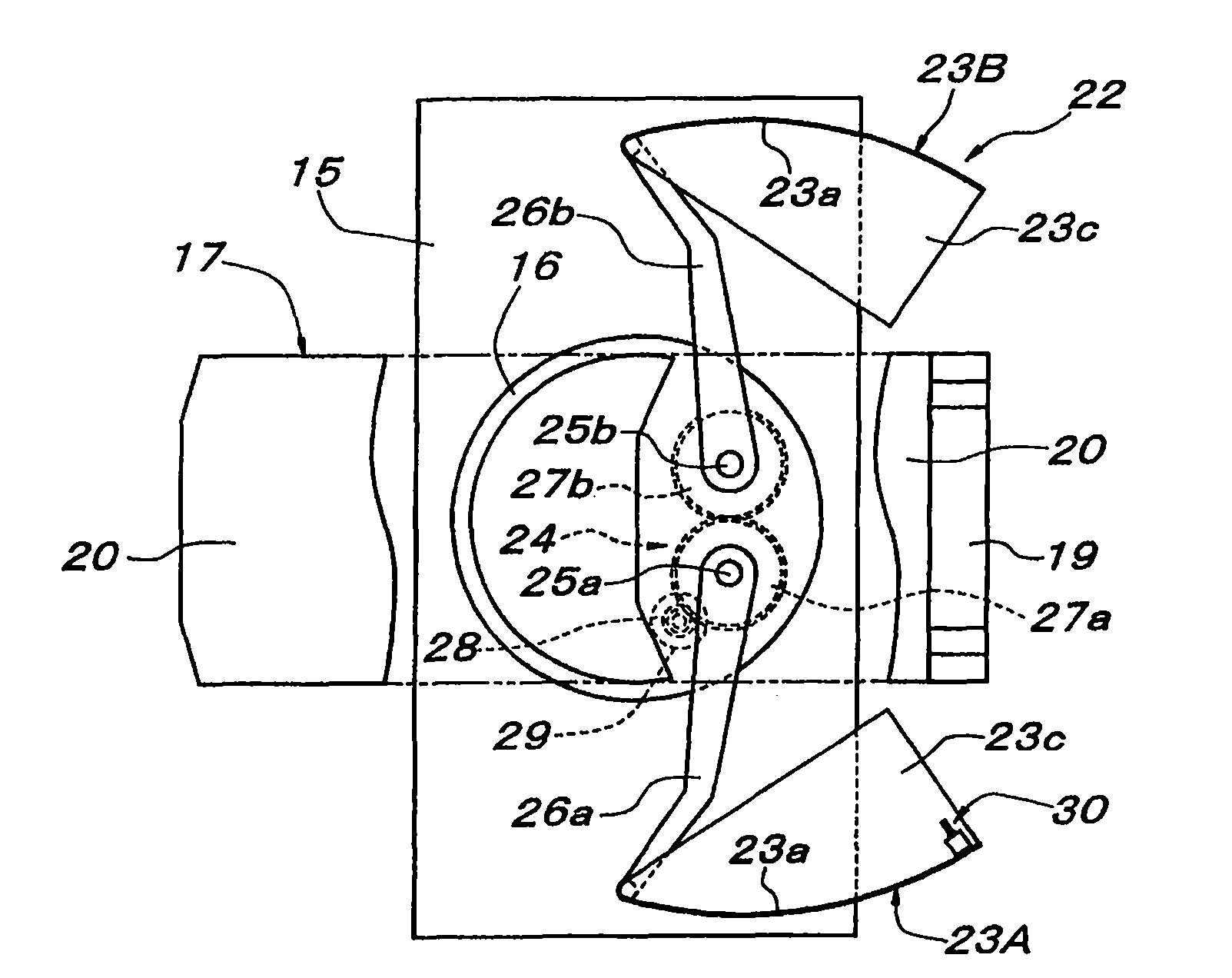

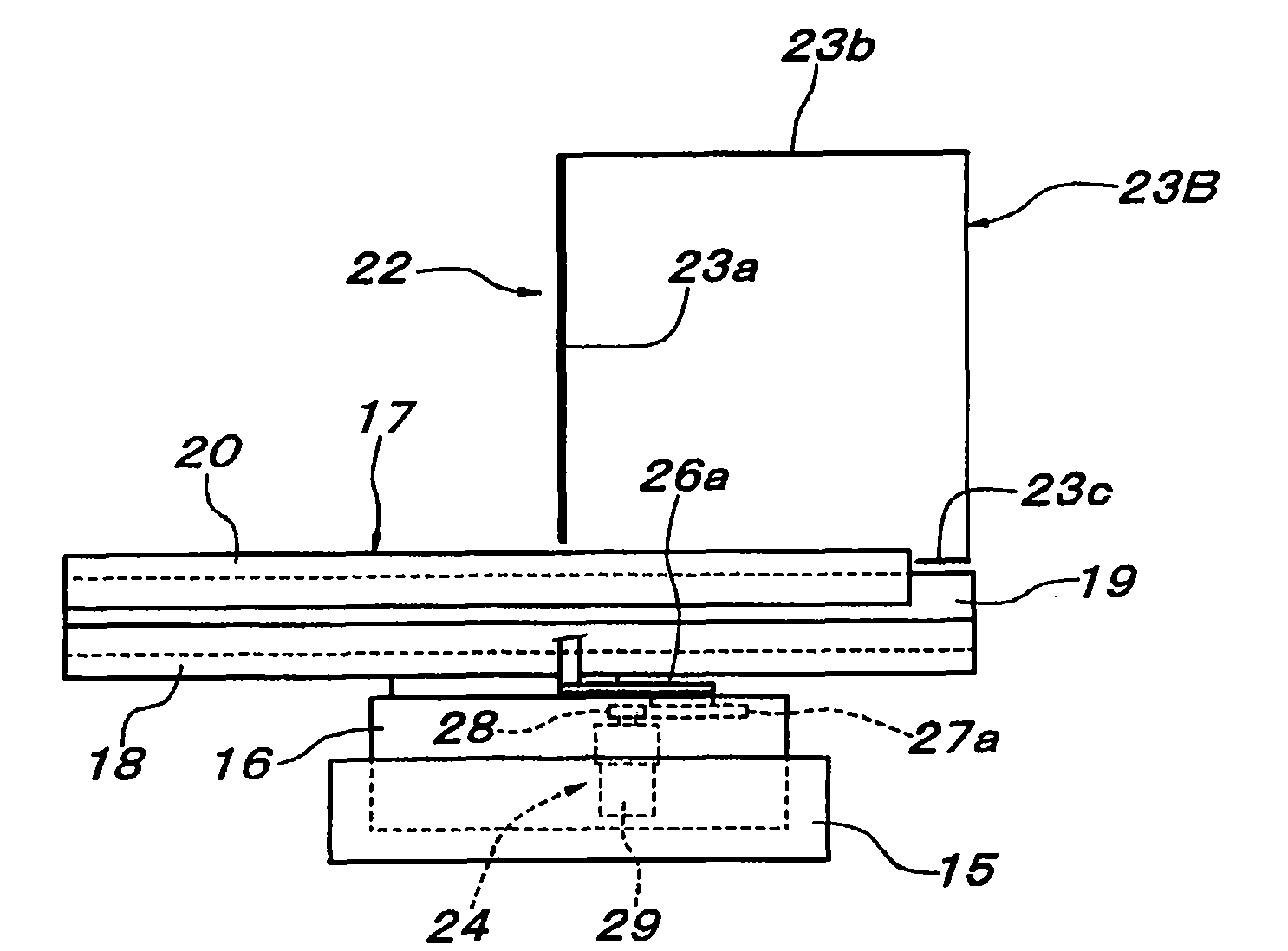

[0068] based on Figure 1 to Figure 11 First embodiment of the present invention is described as follows: as figure 1 As shown, the cassette conveying device (カセツト conveying device) 1 of the present invention is supported by a support guide rail 4 laid on the ground in the walking path 3 between two rows of frame bodies 2A and 2B arranged side by side, and along the two rows Frame body 2A, 2B walks by itself. On the two frame bodies 2A, 2B, a cassette storage compartment 7 is three-dimensionally arranged, and the cassette storage compartment 7 accommodates the clean cassette 6, and a single cassette storage compartment 7 is respectively provided at the frame body 2A on one side to form a The substrate unloading operation part 8 and the substrate loading operation part 9 are provided, and the substrate unloading robot device 12 and the substrate storage robot device 13 are provided at the same time. In the cassette 6, the substrates 10 are taken out one by one and carried int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com