Removing device for beverage bottle having high bottle cap of beverage filling machine

A technology of rejecting device and filling machine, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of lack of external protection structure, short service life, easy to be affected by the outside world, etc., and achieve convenient transportation, detection and rejection The effect of high bottle precision and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

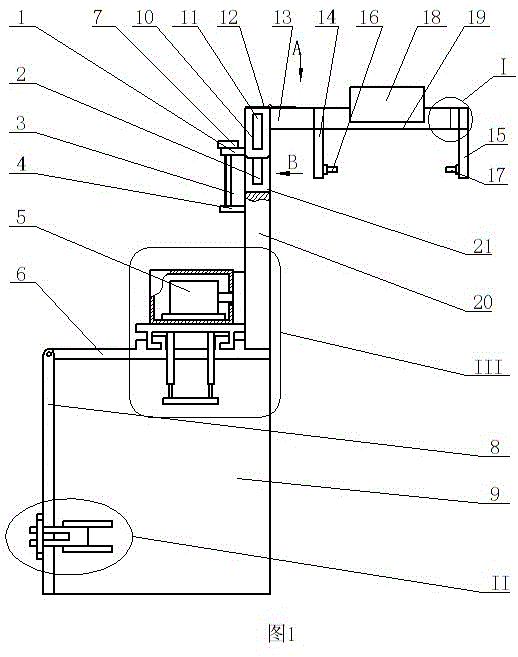

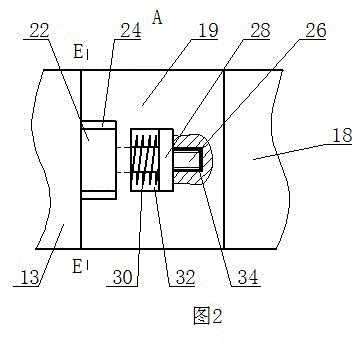

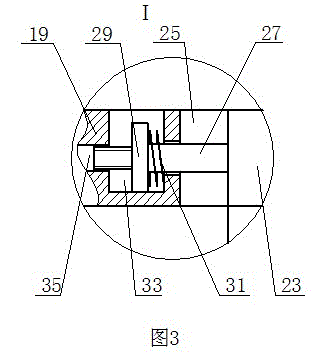

[0009] The device for removing beverage bottles with high caps for a beverage filling machine according to the present invention comprises a base plate 6 on which a front support plate 20, two side support plates 9 and a rear support plate 8 are installed respectively, the lower end of the rear support plate 8 and The lower ends of the two side support plates 9 are respectively hinged with the bottom plate 6, and the hinged mode may be an existing hinge connection, etc., so as to ensure that the rear support plate 8 and the two side support plates 9 are turned down 180 degrees relative to the bottom plate 6 respectively. The top plate is installed on the front support plate 20, and the top plate is composed of a connecting block 13, a first guide rod 26, a mounting plate 19, a transmitter mounting plate 14, a receiver mounting plate 15 and a second guide rod 27. The connecting block 13 is hinged with the upper end of the front support plate 20 through the hinge 12, the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com