Reinforced wood floor with three-dimensional decorative texture structure and manufacturing method thereof

A technology for strengthening wood floors and textures, which is applied in building structures, floors, buildings, etc., can solve the problems of inability to provide a three-dimensional sense of wood texture, and the three-dimensional sense is not strong, and achieve the effect of realistic wood texture decoration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail through the following specific embodiments, combined with the description of the accompanying drawings.

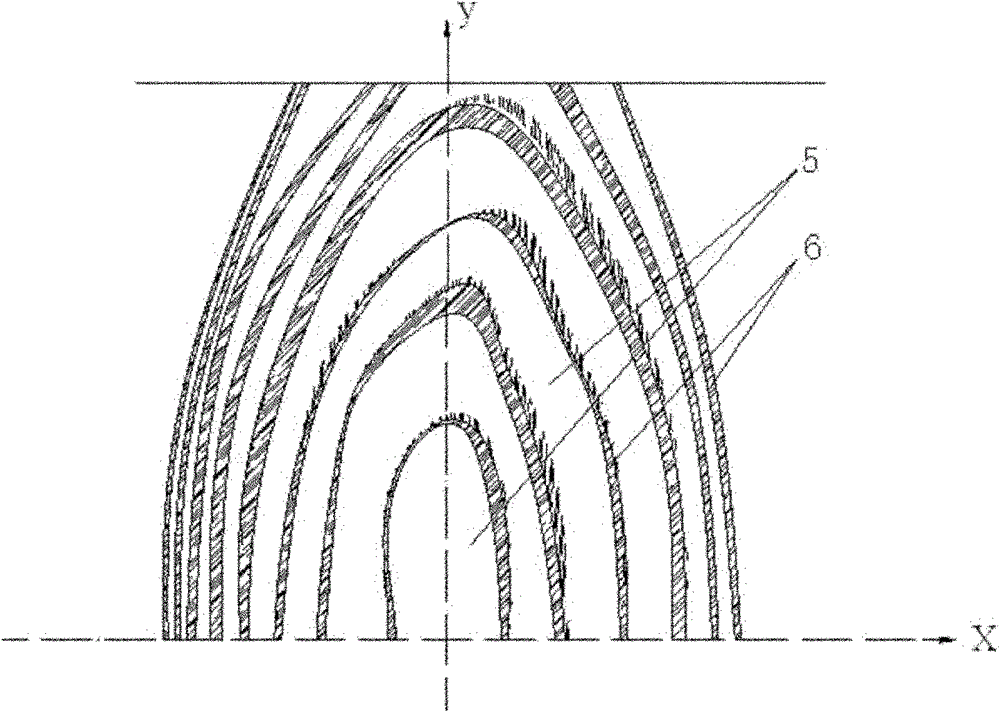

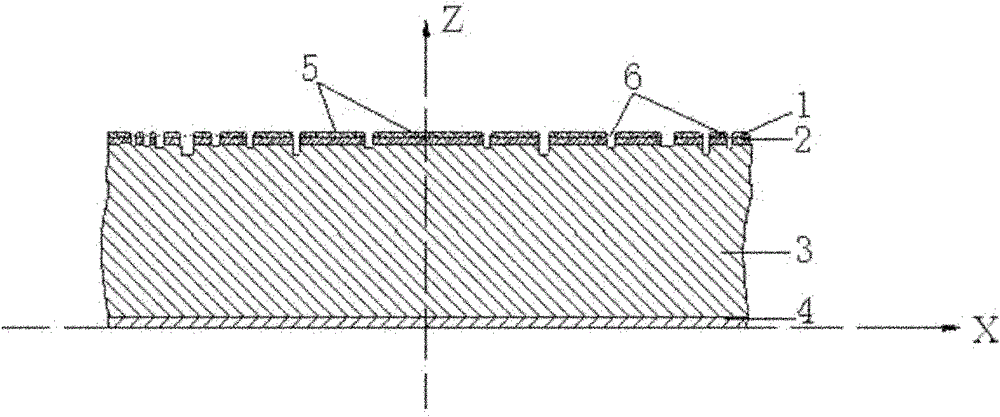

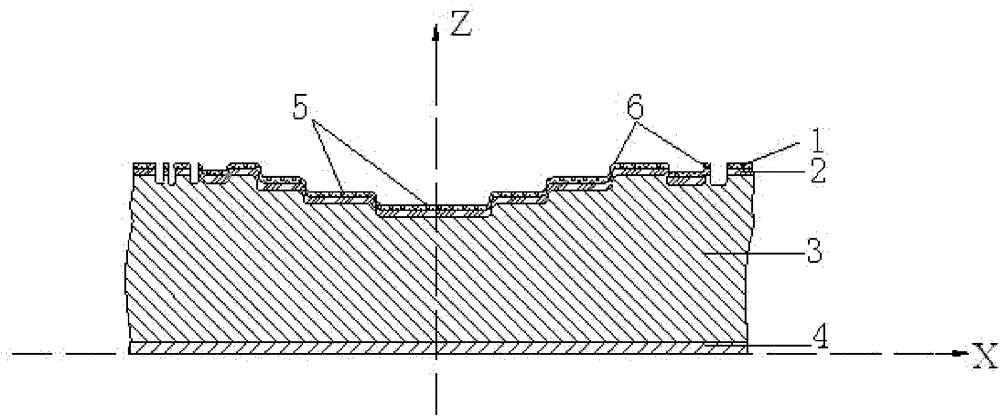

[0021] figure 1 , figure 2 , image 3 It shows the laminated flooring with three-dimensional decorative texture structure of the present invention, which includes a wear-resistant layer 1, a decorative layer 2, a base material layer 3 and a balance layer 4 connected sequentially from top to bottom, and the wear-resistant layer 1 The upper surface 5 has a texture 6 corresponding to the wood texture pattern printed in the decorative layer 2 , and there is a height difference between the upper surface 5 on two adjacent sides of the texture 6 .

[0022] This height difference is preferably 0.01 mm to 0.2 mm (ie 1 to 20 wires). The texture 6 is a circular arc transition area or a right angle transition area or a bevel transition area between the upper surfaces 5 with height differences.

[0023] Through the above des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com