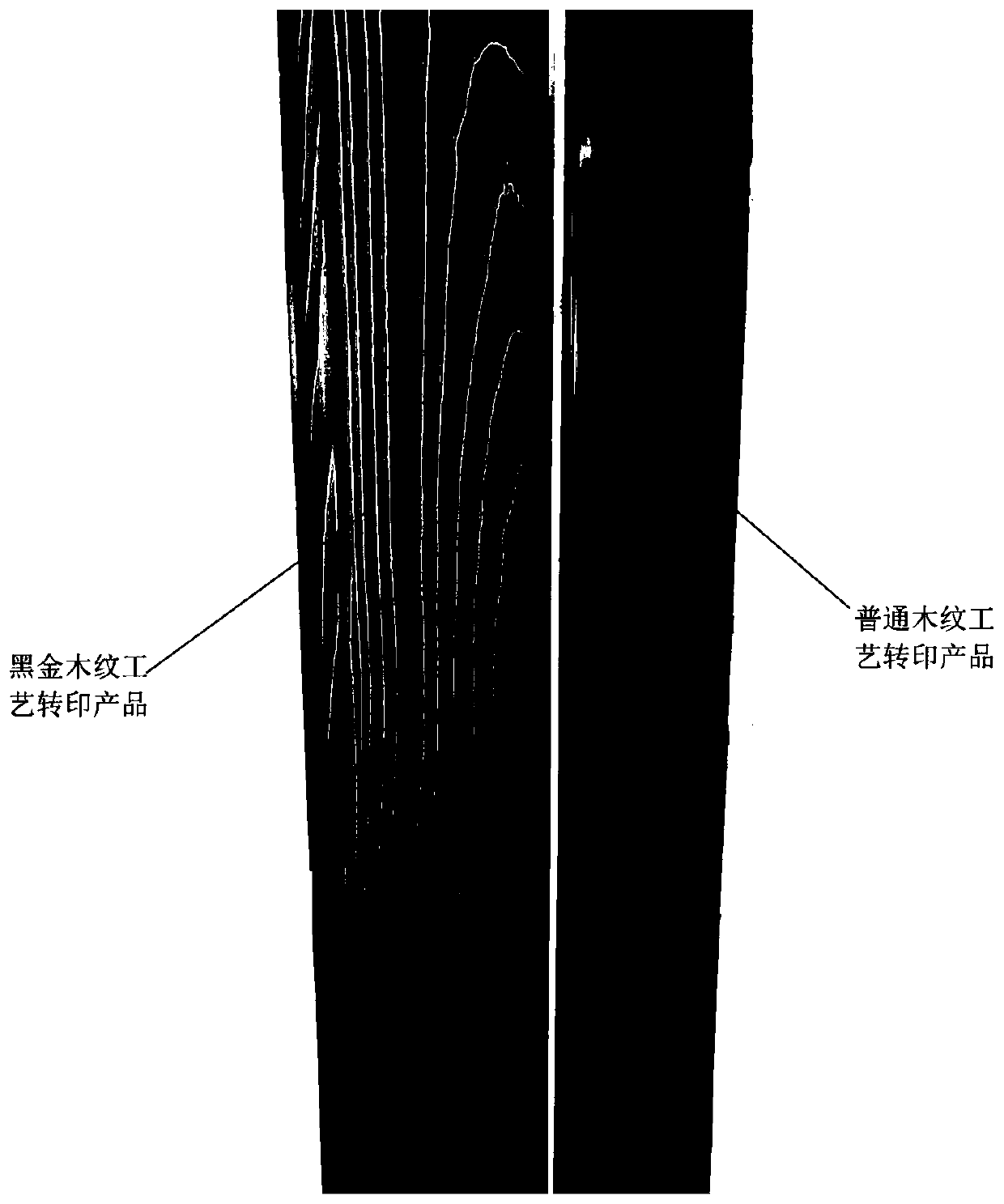

A kind of aluminum alloy anodic oxidation surface black gold wood grain production process and product

A kind of technology of anodizing and production process, which is applied in the direction of anodizing, printing and printing process for the production of special varieties of printed matter, etc. It can solve the problems of large texture difference, wear resistance, high temperature and humidity resistance, UV resistance and aging resistance. , Fading and other problems, to achieve the effect of improving wear resistance and weather resistance, expanding the scope of use, and strong visual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Pretreatment process: place the blank aluminum profile in the chemical polishing tank, and control the configuration ratio of the chemical polishing solution: 85% phosphoric acid: 45-55%, 97% sulfuric acid: 25-32%, nitric acid: 2-6 %, the balance is water, soak the profile in the polishing solution for 3-5 minutes, and the soaking temperature is 95-120°C. After the treatment is completed, wash the surface with water to obtain a high-gloss surface for the billet aluminum profile;

[0024] (2) Anodic oxidation process: put the finished aluminum profile in the step (1) into an anodic oxidation tank for electrolytic oxidation treatment, and control the concentration of industrial sulfuric acid (97%) in the oxidation tank bath solution to be 150~200g / L, The temperature is 18~20℃, the current density is 1.2~1.5A / dm 2 , the oxidation time is 30-50 minutes, and then the surface is cleaned to obtain a colorless and transparent anodic oxidation film; the aluminum profile is p...

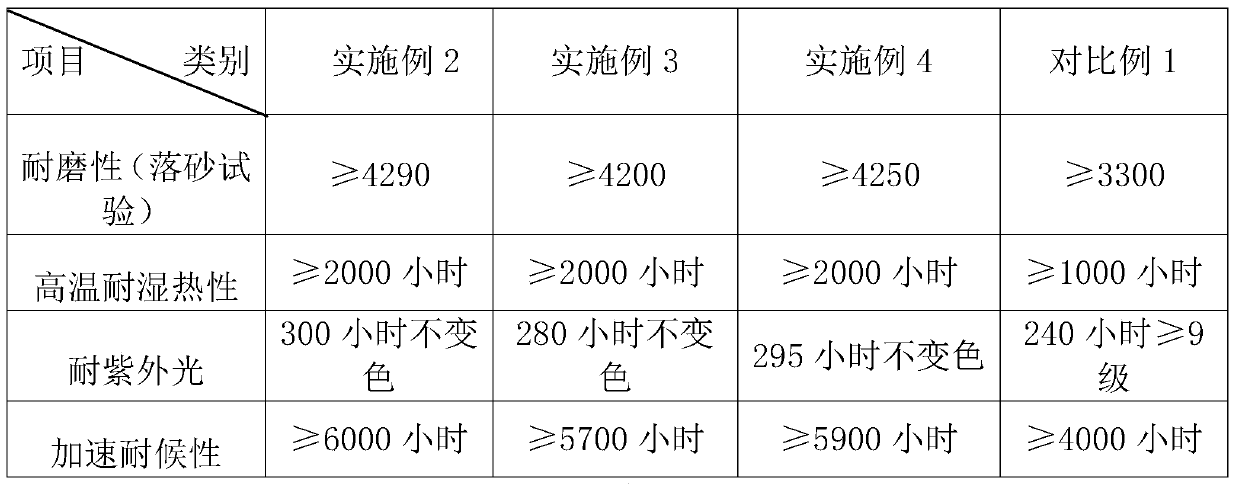

Embodiment 2

[0034] (1) Pretreatment process: place the blank aluminum profile in the chemical polishing tank, control the configuration ratio of the chemical polishing solution: 85% phosphoric acid 50%, 97% sulfuric acid 28%, nitric acid 4%, water 18%, the profile in Soak in the polishing solution for 4 minutes, and the soaking temperature is 108°C. After the treatment is completed, wash the surface with water to obtain a high-gloss surface for the billet aluminum profile;

[0035] (2) anodic oxidation process: put the aluminum profile that has been processed in the step (1) into an anodic oxidation tank and carry out electrolytic oxidation treatment, and the concentration of industrial sulfuric acid (97%) in the control oxidation tank bath is 175g / L, and the temperature is 19℃, the current density is 1.35A / dm 2 , the oxidation time is 40min, and then the surface is cleaned to obtain a colorless and transparent anodic oxidation film;

[0036] (3) Electrolytic coloring: the aluminum profi...

Embodiment 3

[0040] (1) Pretreatment process: put the blank aluminum profile in the chemical polishing tank, and control the configuration ratio of the chemical polishing solution: 85% phosphoric acid: 45%, 97% sulfuric acid: 25%, nitric acid: 2%, water: 28% , soak the aluminum profile in the polishing solution for 5 minutes, the soaking temperature is 95°C, after the treatment is completed, wash the surface with water, so that the billet aluminum profile can get a high-gloss surface;

[0041] (2) anodic oxidation process: put the aluminum profile that has been processed in the step (1) into an anodic oxidation tank and carry out electrolytic oxidation treatment, and the concentration of industrial sulfuric acid (97%) in the control oxidation tank bath is 200g / L, and the temperature is 18℃, the current density is 1.2A / dm 2 , the oxidation time is 30min, and then the surface is cleaned to obtain a colorless and transparent anodic oxidation film;

[0042] (3) Electrolytic coloring: the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com