Sand-in-water imitation granite coating and preparation method thereof

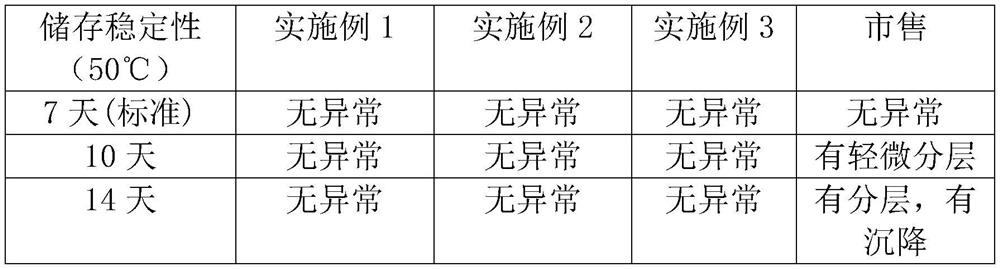

A technology imitating granite and paint, applied in the direction of coating, etc., can solve the problems of short storage time, poor granulation texture, poor storage stability, etc., and achieve the effect of strong three-dimensional texture, full granulation, and improved storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A sand-in-water imitation granite coating, comprising the following components:

[0032] The composition of the protective colloid solution by weight: 93 parts by weight of water, 7 parts by weight of bentonite; for preparation, first add water to the dispersion tank, add bentonite under the stirring condition of 600-1200r / min, and disperse until the protective colloid is fully dissolved without particles sense, stand for 2 hours for later use;

[0033] The mixed color point is a multi-color point, and the color point includes the following components by weight: 0.2 parts of preservatives, 0.5 parts of hydroxyethyl cellulose, 0.5 parts of propylene glycol, 0.1 parts of pH regulator, 0.5 parts of defoaming agent, and 0.2 parts of wetting agent 0.3 parts of dispersant, 1 part of rutile titanium dioxide, 5 parts of kaolin, 15 parts of acrylic emulsion, 1 part of suspending agent, 0.5 parts of thickener, 5 parts of 40-80 crystal white sand, 5 parts of 80-120 crystal white s...

Embodiment 2

[0038] A sand-in-water imitation granite coating, comprising the following components:

[0039] The composition of the protective colloid solution by weight: 93.5 parts by weight of water, 6.5 parts by weight of bentonite; for preparation, first add water to the dispersion tank, add bentonite under the stirring condition of 600-1200r / min, and disperse until the protective colloid is fully dissolved without particles sense, stand for 2 hours for later use;

[0040] The mixed color point is a multi-color point, and the color point includes the following components by weight: 0.2 parts of preservatives, 0.5 parts of hydroxyethyl cellulose, 0.5 parts of propylene glycol, 0.1 parts of pH regulator, 0.5 parts of defoaming agent, and 0.3 parts of wetting agent 0.4 parts of dispersant, 1 part of rutile titanium dioxide, 6 parts of kaolin, 15 parts of acrylic emulsion, 1.2 parts of suspending agent, 0.6 parts of thickener, 7 parts of 40-80 crystal white sand, 7 parts of 80-120 crystal ...

Embodiment 3

[0045] A sand-in-water imitation granite coating, comprising the following components:

[0046] The composition of the protective colloid solution by weight: 92.5 parts by weight of water, 7.5 parts by weight of bentonite; for preparation, first add water to the dispersion tank, add bentonite under the stirring condition of 600-1200r / min, and disperse until the protective colloid is fully dissolved without particles sense, stand for 2 hours for later use;

[0047] The mixed color point is a multi-color point, and the color point includes the following components by weight: 0.2 parts of preservatives, 0.5 parts of hydroxyethyl cellulose, 0.5 parts of propylene glycol, 0.1 parts of pH regulator, 0.5 parts of defoaming agent, and 0.3 parts of wetting agent 0.5 parts of dispersant, 1.5 parts of rutile titanium dioxide, 7 parts of kaolin, 16 parts of acrylic emulsion, 1.4 parts of suspending agent, 0.7 parts of thickener, 9 parts of 40-80 crystal white sand, 9 parts of 80-120 cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com