High-power LED panel lamp for metro lighting

An LED panel light and high-power technology, which is applied to the parts of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of difficult heat dissipation of high-power LED lamp beads, hidden safety hazards, and heavy lamps and lanterns. , to achieve the effect of high light output efficiency and reliability, convenient disassembly and maintenance, and uniform brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

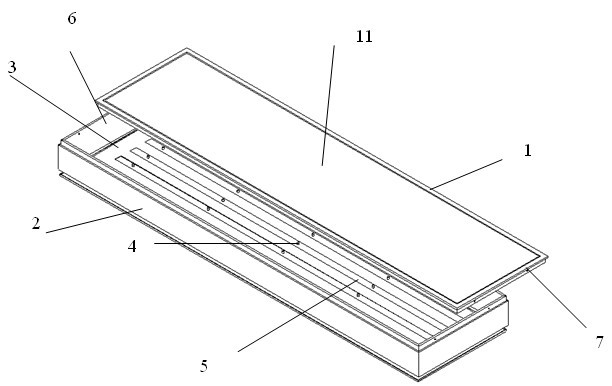

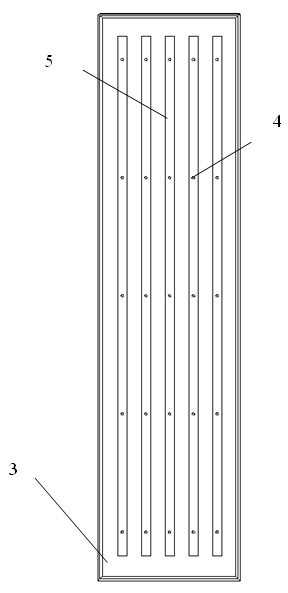

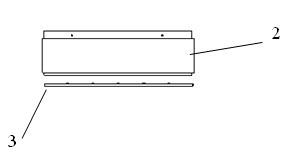

[0022] Such as Figure 1~3 , a high-power LED panel light for subway lighting, comprising a bottom aluminum plate 3, a lamp front cover 1, a lamp side frame 2 and a strip-shaped aluminum substrate 9, the bottom aluminum plate 3 and the lamp side frame 2 are connected to form a lamp with an opening The shell, the edge of the opening is connected with the edge of the front cover 1 of the lamp to form a space, and the aluminum plate 3 on the bottom surface is stamped with a number of grooves 5 for installing the long aluminum substrate, wherein the screw 4 is fixed in the middle of the groove 5, and the groove The long side of 5 is parallel to the long side of the bottom aluminum plate 3, several grooves 5 are equidistantly distributed along the sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap