Oil pressure drafting device of dry-variable casting coil

A casting coil and oil pressure technology, which is applied in coil manufacturing and other directions, can solve the problems of occupying operating space, affecting the lifting and placement of casting coils, and cannot guarantee the smooth completion of the drafting process, so as to simplify the drafting process and improve the drafting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

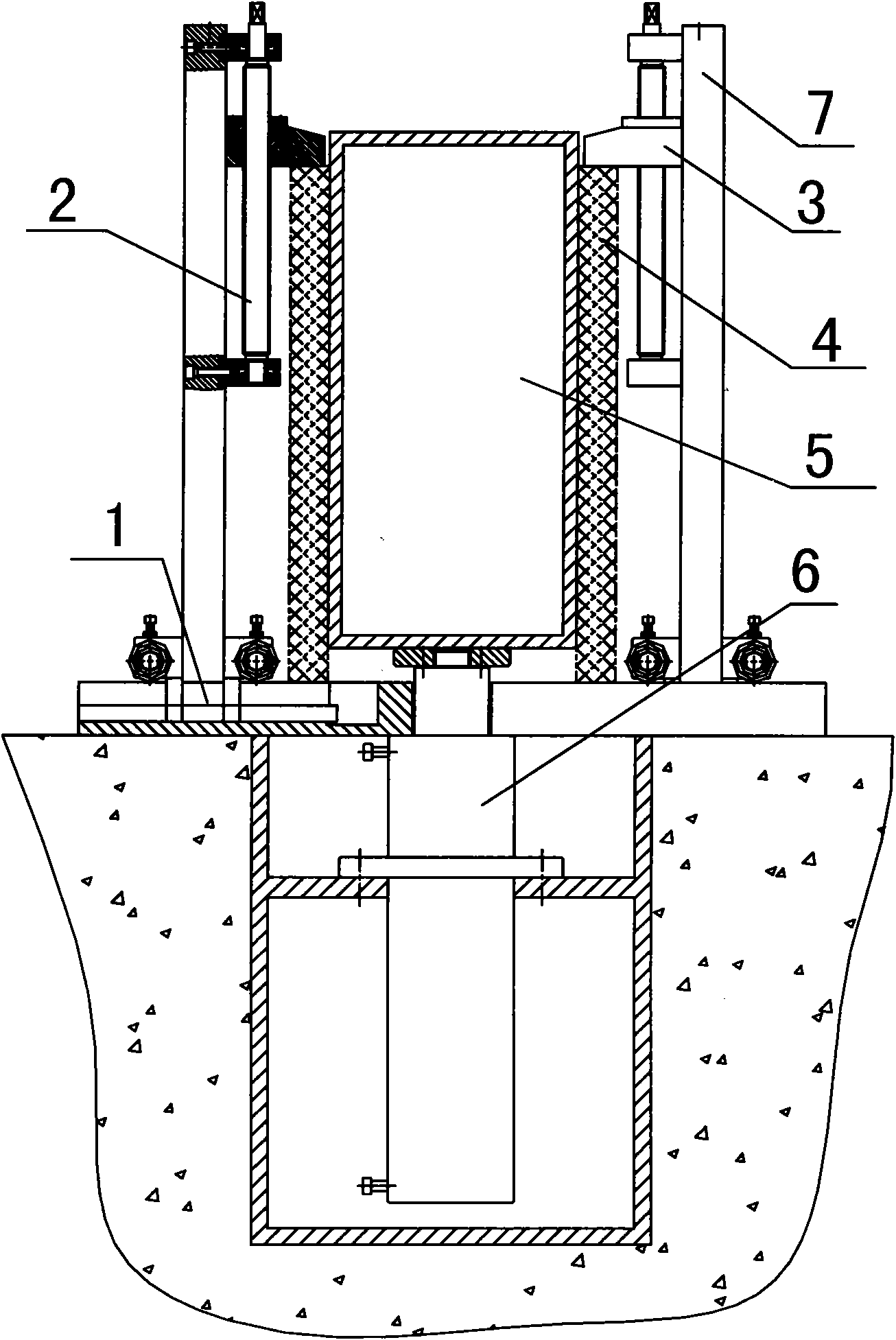

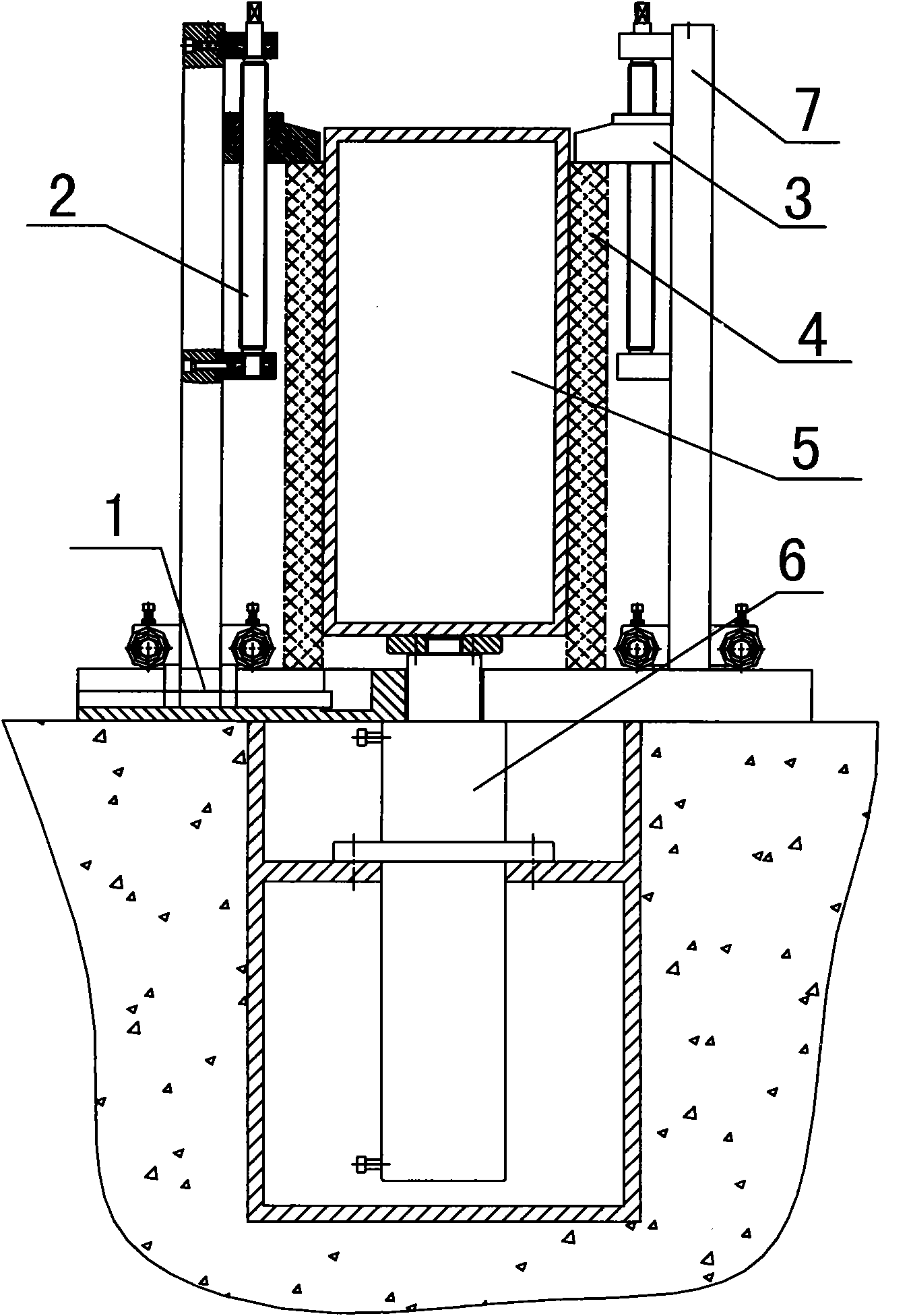

[0010] Such as figure 1 A hydraulic drawing device for dry variable casting coils is shown, including a support 7, a coil mold 5 and an oil cylinder 6, the oil cylinder 6 is located underground; the support 7 is provided with a pressing block 3, and the pressing block 3 is movable; the pressing block 3 is movable through the screw rod 2; the bottom of the bracket 7 is also provided with a slide groove 1.

[0011] According to the diameter of the compressible coil 4, the lateral position of the support 7 is adjusted through the T-shaped chute 1 of the lower base plate, and then the axial position of the briquetting block 3 is adjusted through the screw 2 according to the height of the compressible coil 4, and then the poured The compressible coil 4 is placed therein, and the pressing block 3 is firmly pressed on the upper end of the compressible coil, and finally the oil pressure control system is started to lift the piston of the oil cylinder 6 to realize the drafting.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com