Grid beam construction method and mold withdrawing device of grid beam

A construction method and technology of lattice beams, applied in the processing of formwork, formwork/formwork/work frame, building components, etc., can solve the problems of inability to recycle, increase construction costs, and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0049] First, see figure 1 , figure 2 , image 3 and Figure 4 .

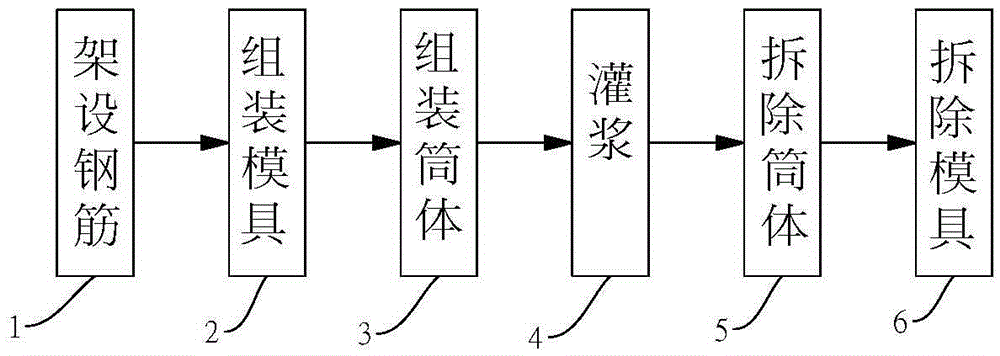

[0050] The construction method of lattice beam of the present invention and related device thereof, its steps are as follows:

[0051] (1). Erection of steel bars 1, enclosing several accommodation spaces 110 by a plurality of steel bars 100 in a criss-cross pattern.

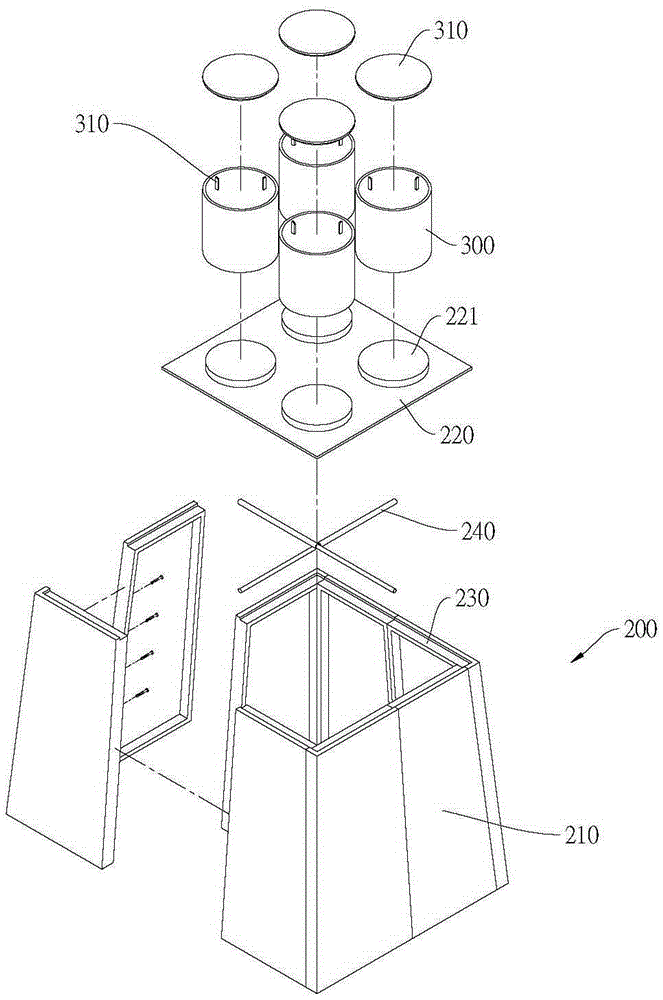

[0052] (2). Assemble the mold 2, and install the mold 200 in the above-mentioned accommodating space 110. The mold 200 includes a plurality of templates 210 and a top plate 220. A groove-shaped corresponding portion 230 is formed above, and the top plate 220 is embedded in the corresponding portion 230 , and a protruding block 221 is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com