LED (Light-Emitting Diode) lamp driving circuit

A technology for driving circuits and LED lamps, which is applied to the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of increased power consumption of sampling resistors, increased costs, and uncontrollable power consumption of current sharing circuits, etc., to improve drive efficiency, The effect of simple circuit and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

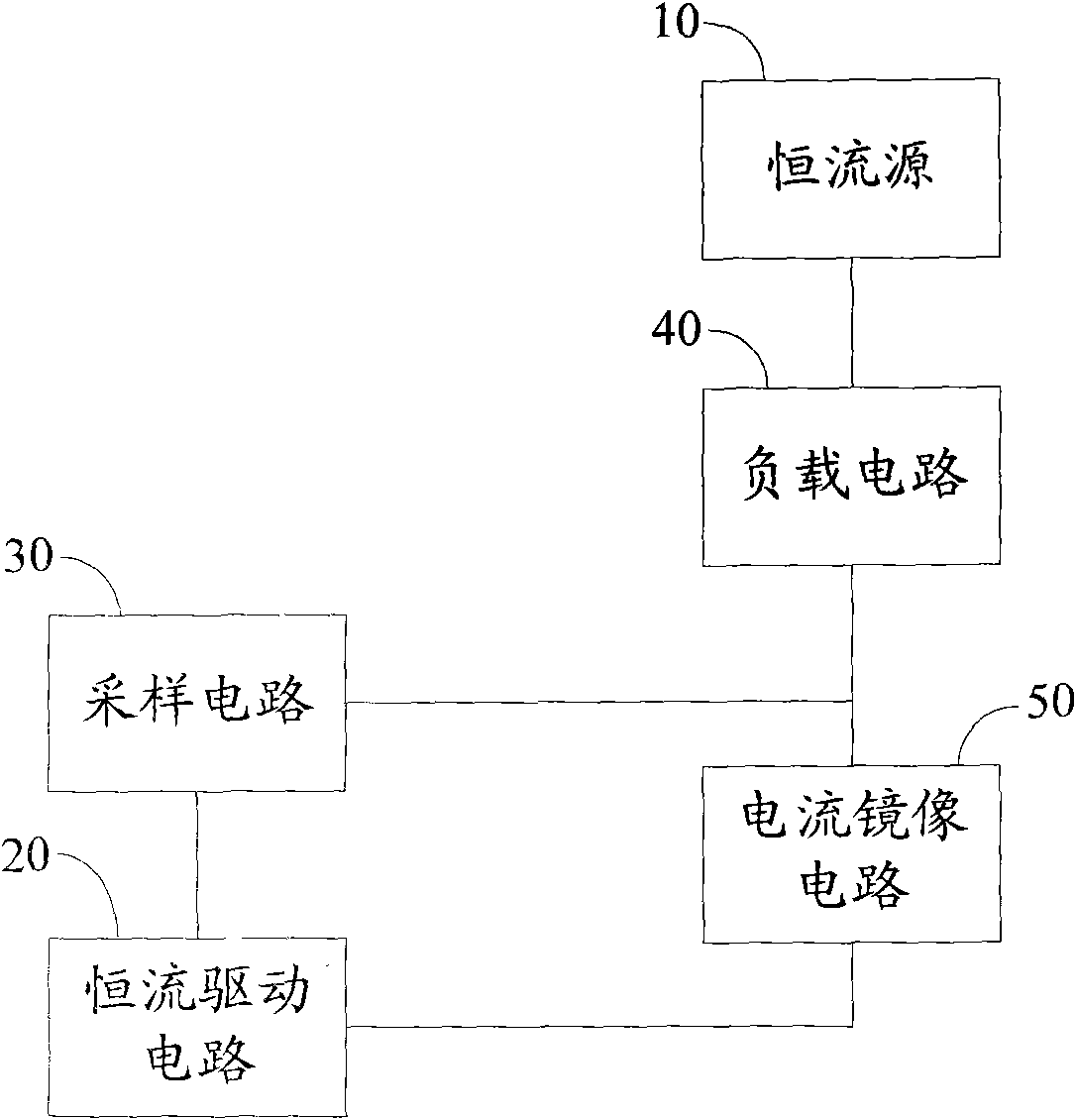

[0024] figure 1 It is a structural schematic diagram of an embodiment of the LED lamp driving circuit of the present invention.

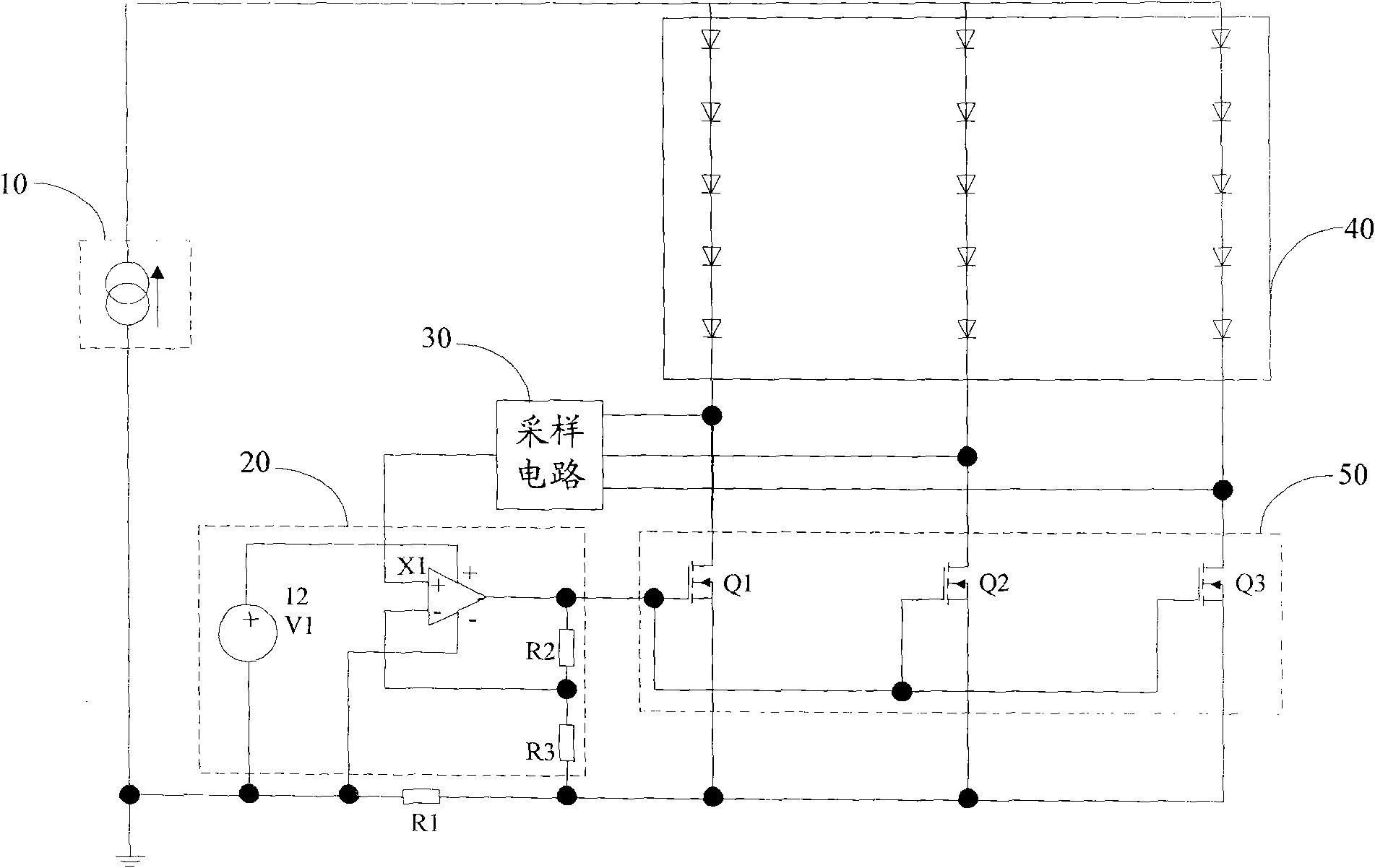

[0025] The LED lamp driving circuit of this embodiment adopts a constant current source and multiple current mirror circuits to form a multi-channel constant current equalizing circuit, including a constant current source 10, a constant current drive circuit 20, a sampling circuit 30, at least one load circuit 40 and a load circuit. Circuit 40 corresponds to a current mirror circuit 50 connected thereto. Wherein, the multi-channel load circuit 40 is connected in parallel with the constant current source 10 . The sampling circuit 30 is used to collect the voltage of the logical combination of the current mirror circuit 50 . The constant current drive circuit 20 is connected to one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com