Heat treatment method for rolling bearing device for wheel and cooling device for inner shaft

A heat treatment method and rolling bearing technology, applied in heat treatment furnaces, bearing components, heat treatment equipment, etc., can solve the problems of irregular discoloration of the outer peripheral surface, achieve uniform thickness and diffusion, suppress hardening irregularities, and omit the effect of turning steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] With reference to the drawings, embodiments of the present invention will be specifically described below.

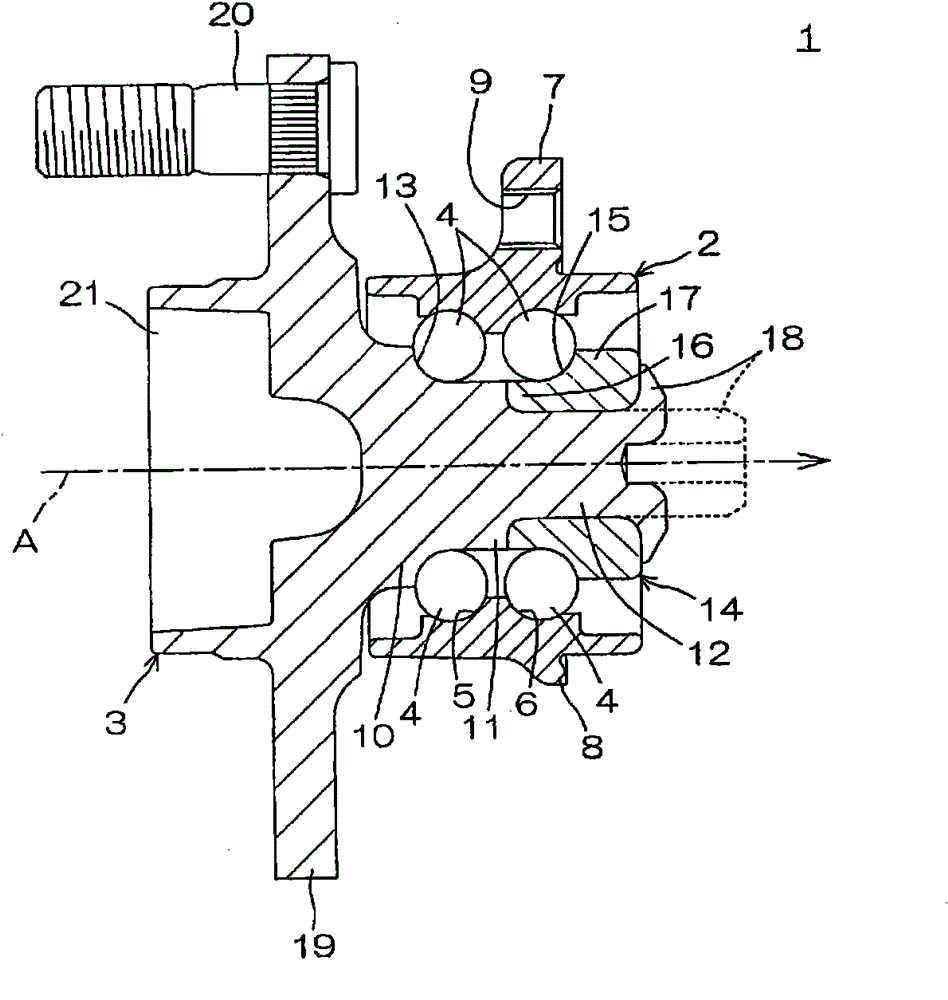

[0039] As mentioned above, figure 1 It is a cross-sectional view showing an example of the rolling bearing device 1 for a wheel. reference figure 1 , The rolling bearing device 1 for a wheel includes an outer ring 2, an inner shaft 3, and a plurality of rolling elements 4. The outer ring 2 has a tube shape, and the inner shaft 3 is inserted into the tube and shared with the outer ring 2 around the axis A Arranged axially, the rolling elements 4 are placed between the outer ring 2 and the inner shaft 3.

[0040] Double rows (two rows in the figure) track surfaces 5 and 6 for supporting the rolling elements 4 for rolling are formed on the inner circumference of the tube of the outer ring 2. Also, on the outer circumference of the tube, the flange 8 is formed integrally with the tube to protrude outward in the radial direction of the tube from a plurality of positions (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com