Tobacco composition in flue-cured type cigarettes

A flue-cured tobacco-type cigarette and composition technology, which is applied in the fields of tobacco, food science, and tobacco preparation, can solve the problem that the inventory of tobacco leaves cannot meet the needs of the development of first- and second-class cigarette brands, and achieve the ability to ensure sustainable development , Alleviate dependence and improve utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

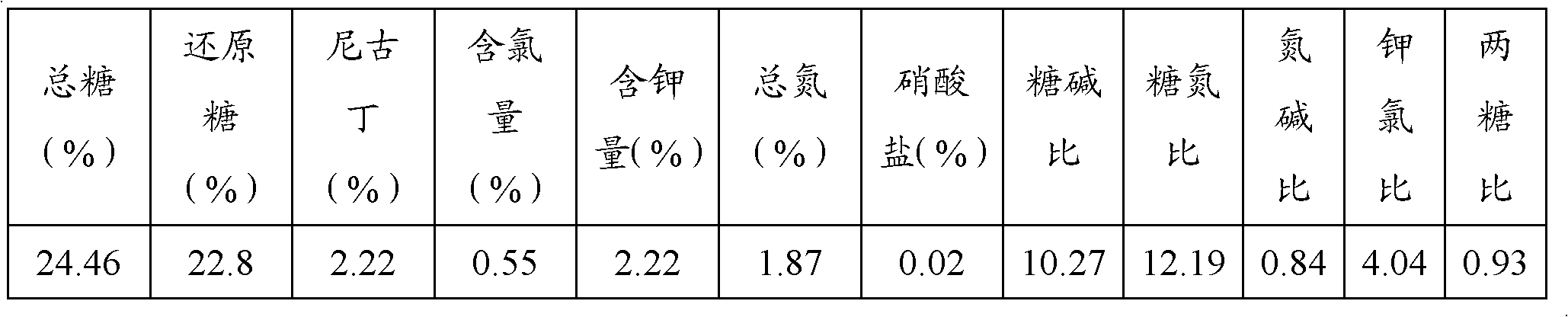

[0032] Take 500g of Hubei Enshi middle grade three tobacco leaves with a sugar-base ratio of 10.50, 250g of Yunnan Puer upper grade tobacco leaves with a sugar-base ratio of 9.28, 250g of Guangxi Hezhou middle grade three tobacco leaves with a sugar-base ratio of 11.25, and Guizhou with a sugar-base ratio of 10.85 500g of secondary tobacco leaves in the middle part of Tongren were cut into shredded tobacco and mixed evenly to prepare the tobacco leaf composition in flue-cured cigarettes.

Embodiment 2

[0034] Take 750g of the third-grade tobacco leaves in the middle part of Hubei Enshi with a sugar-base ratio of 10.50, 250g of the upper-grade tobacco leaves of Yunnan Puer with a sugar-base ratio of 9.28, 500g of the third-grade tobacco leaves in the middle of Guangxi Hezhou with a sugar-base ratio of 11.25, and Guizhou with a sugar-base ratio of 10.85. 250g of secondary tobacco leaves in the middle part of Tongren were cut into shredded tobacco and mixed uniformly to prepare the tobacco leaf composition in flue-cured cigarettes.

Embodiment 3

[0036] Take 500g of Hubei Enshi middle grade three tobacco leaves with a sugar-base ratio of 10.50, 500g of Yunnan Pu'er upper grade tobacco leaves with a sugar-base ratio of 9.28, 250g of Guangxi Hezhou middle grade three tobacco leaves with a sugar-base ratio of 11.25, and Guizhou with a sugar-base ratio of 10.85 250g of secondary tobacco leaves in the middle part of Tongren were cut into shredded tobacco and mixed uniformly to prepare the tobacco leaf composition in flue-cured cigarettes.

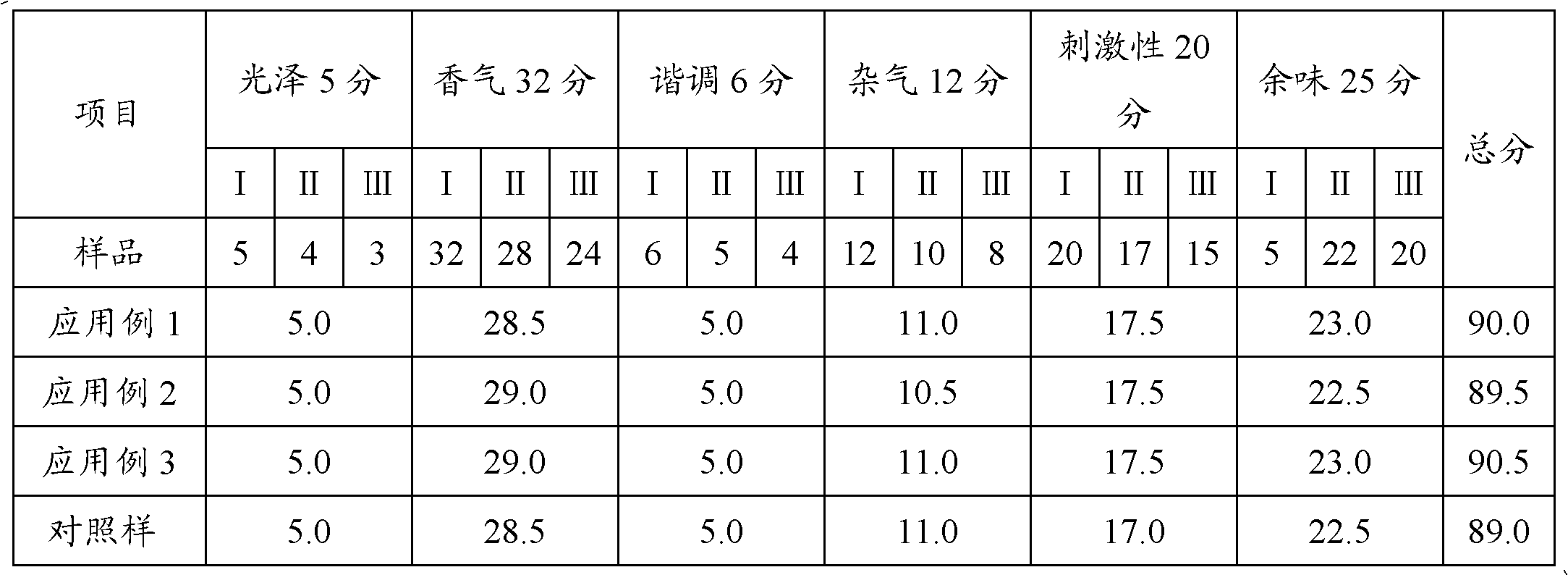

[0037] According to the 9-point system (minimum scale 0.1 point), the comparative smoking evaluation data of the three domestic tobacco leaf compositions prepared in Examples 1-3 and the Canadian tobacco leaves used in the existing Class 1 and Class 2 cigarettes are shown in Table 4.

[0038] Table 4 Sensory quality evaluation table

[0039]

[0040] As can be seen from Table 4, the quality of the domestic tobacco leaf composition of the present invention is equivalent to that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com