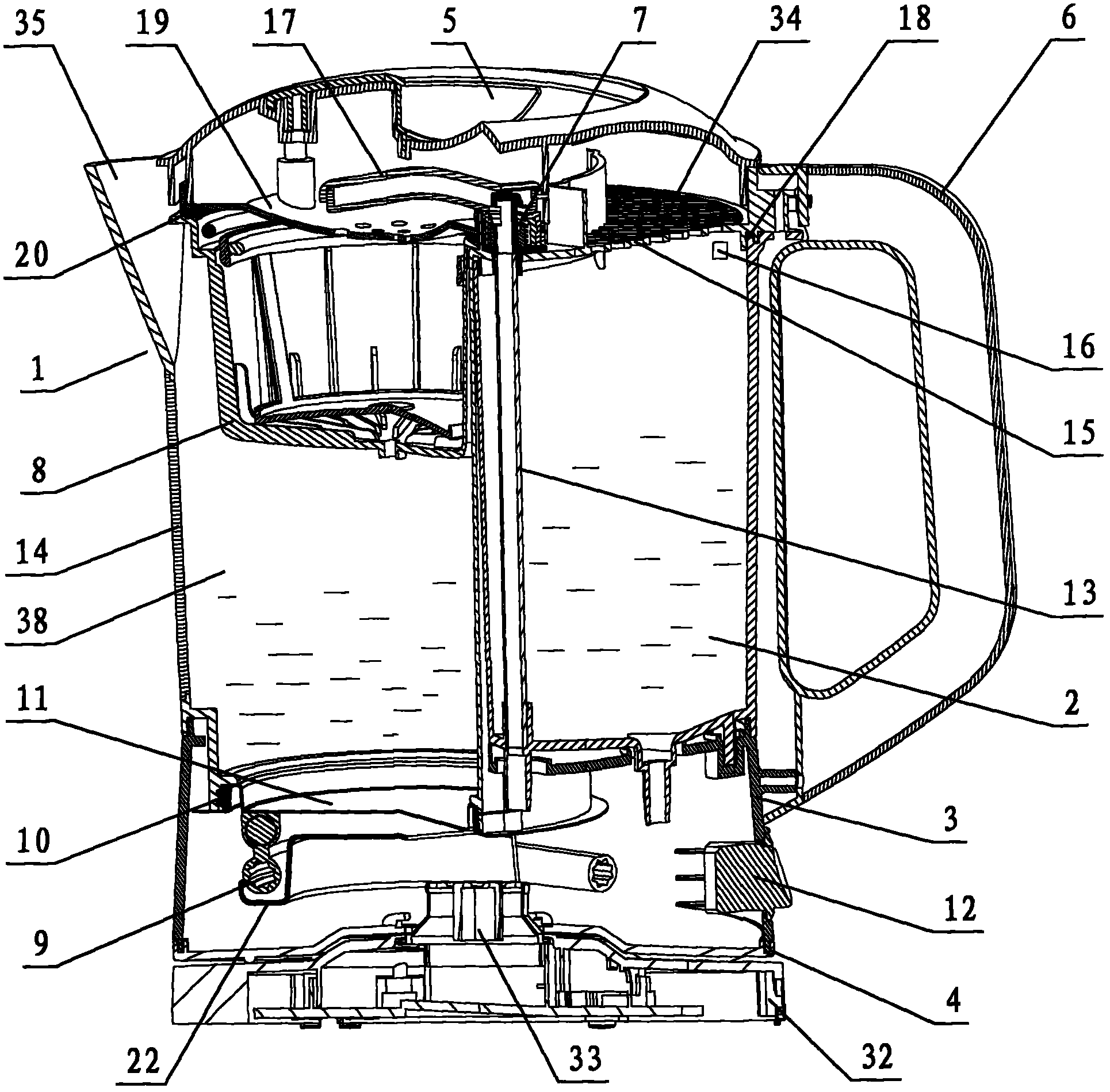

Coffee machine

A coffee machine and coffee technology, which is applied to kitchen utensils, home utensils, beverage preparation devices, etc., can solve the problems of complicated operation process, large heat loss and high production cost, and achieve flexible operation, low production cost and simple and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

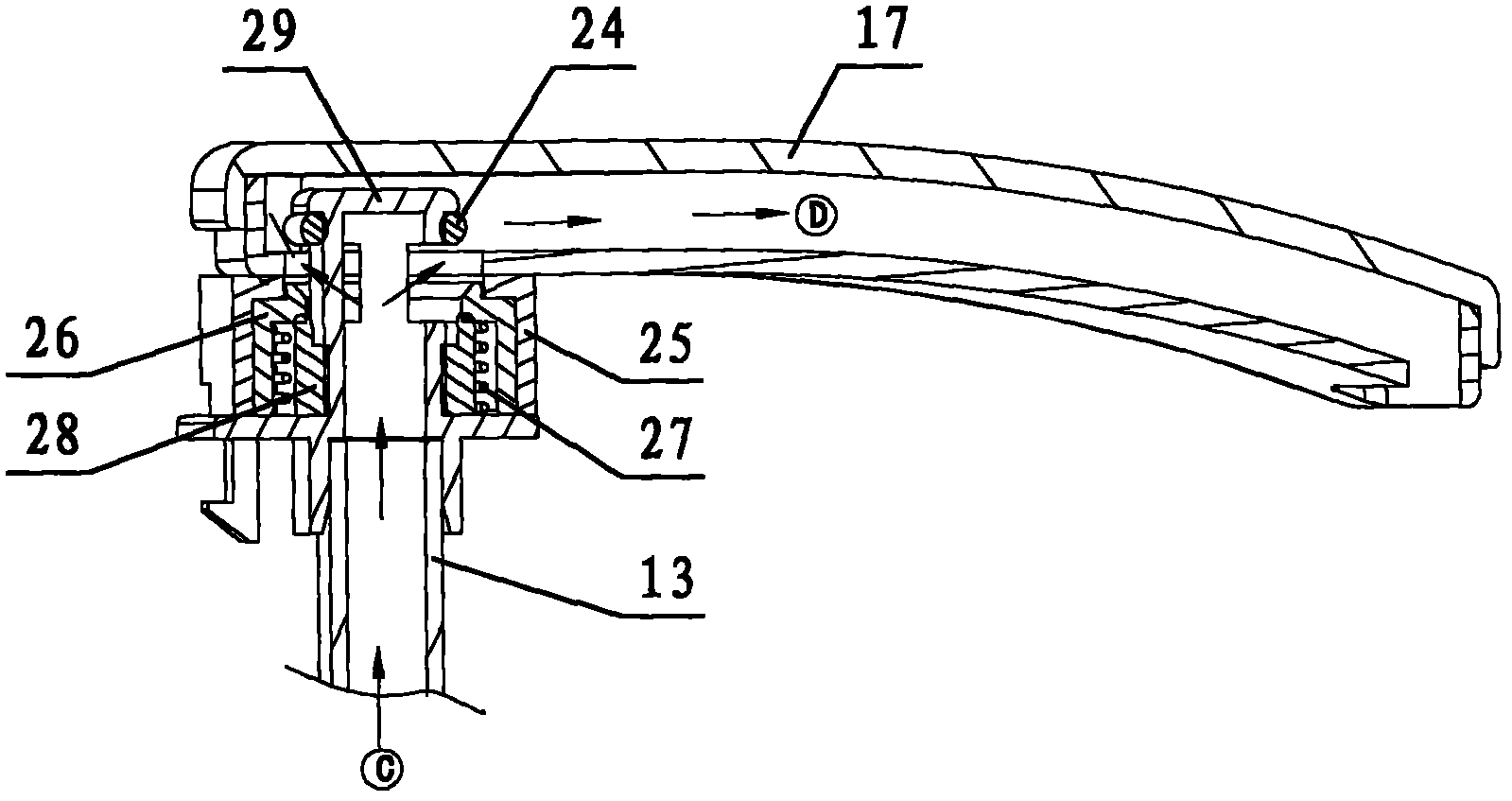

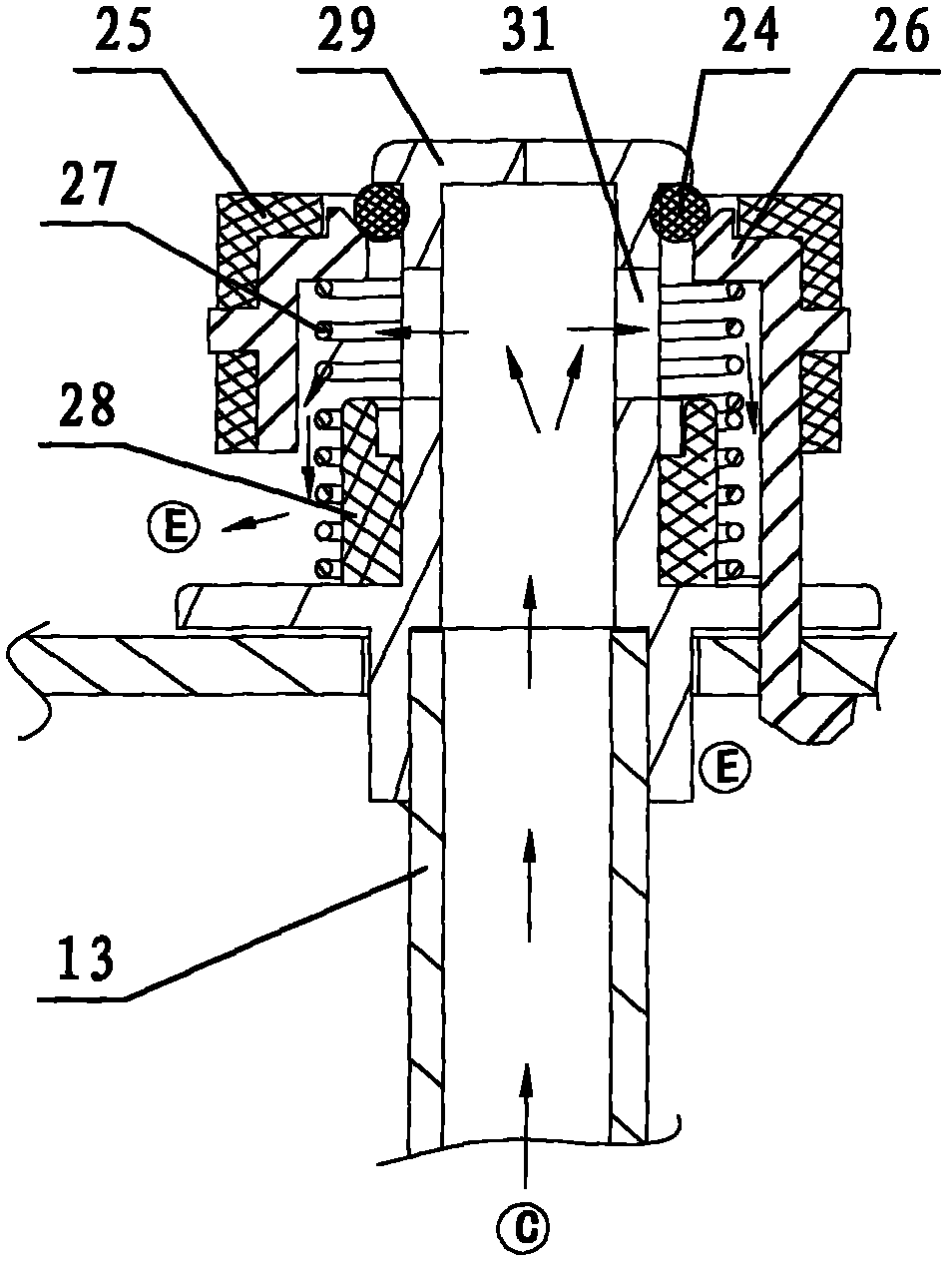

[0036] see Figure 7, the rear side of the top cover 5' is hinged on the top of the fuselage through the top cover shaft 37, and the inner bottom surface of the top cover is provided with an inner cover 19' corresponding to the top of the funnel; the bottom surface of the inner cover is provided with a water seepage hole, and a brewing nozzle 17' is fixed inside The water outlet pipe assembly includes a 7-shaped rotary joint 29', the lower end of which communicates with the pipeline of the heating element through the water outlet pipe 13, and the upper end is provided with a water outlet hole 31' which is rotationally connected and communicated with one end of the brewing nozzle. The other end of the mouth is provided with an opening corresponding to the inner cover. Other unmentioned parts are the same as the first embodiment.

[0037] Its working principle is: when the top cover 5' is flipped open, the brewing nozzle 17' rotates upward around the rotary joint 29' and covers...

no. 3 example

[0039] see Figure 8 and Figure 9 , The coffee storage cavity 40 is connected with the water tank 42 as a whole; the top of the water tank is integrally provided with a water tank cover 41, and the bottom is open and sealed with the bottom plate 43; the front side of the water tank cover 41 is closed to form a water retaining part, and the rear side is provided with a water injection hole. Other unmentioned parts are the same as the first or second embodiment.

no. 4 example

[0041] see Figure 10 and Figure 11 , the coffee storage cavity 38 and the water tank 2 constitute the upper body 1 of the fuselage, the upper body bottom is provided with the lower body 3, the lower body side is provided with a power switch 12, and the bottom surface is provided with a bottom cover 4'. The difference between the bottom cover 4' and the bottom cover in the first embodiment is that the center of the bottom is not provided with a power insertion port that is matched with the power connector. Other unmentioned parts are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com