Digitization bone fracture plate and manufacturing method thereof

A bone plate and bone technology, applied in the direction of electrical digital data processing, external plate, internal bone synthesis, etc., can solve the problems of increasing bone plate, increase in bone plate volume, surrounding tissue and muscle pain, etc., to achieve reduction in body volume, It is not easy to bend and break, and the effect of reducing recurrent fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

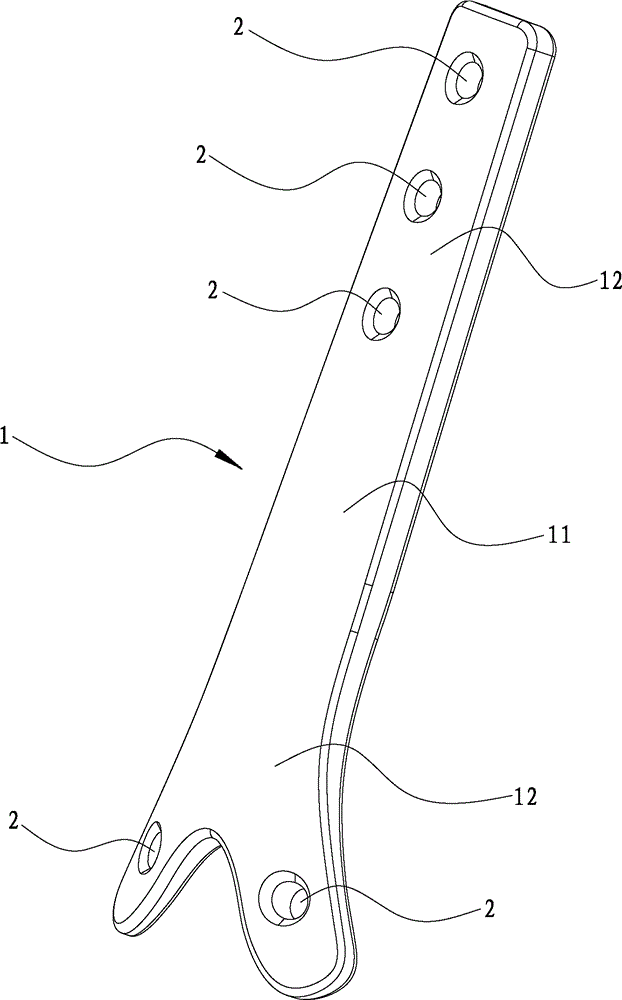

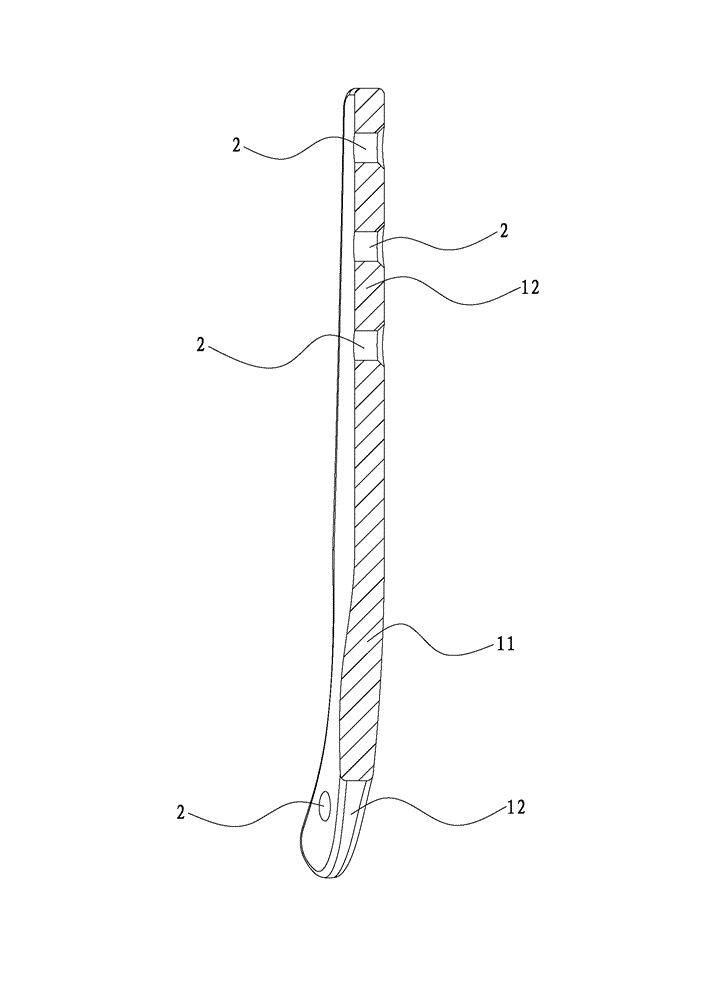

[0027] A digital bone plate, it includes a body 1, the body 1 is provided with a screw hole 2, the body 1 includes a support section 11 arranged on the corresponding broken end of the fracture, and from each end of the support section 11 to the fracture The connection section 12 extended on both sides of the broken end, the screw holes 2 are opened in the connection section 12, the thickness of the connection section 12 is smaller than the support section 11, and the bottom surface of the body 1 is in line with the surface of the bone. Matching arc surface, the top surface of the body 1 smoothly transitions from the supporting section 11 to the connecting section 12 .

[0028] During the use of the bone plate according to the present invention, the body 1 is attached to the surface of the fractured bone, the support section 11 is attached to the broken end of the fracture, and the connecting section 12 is respectively attached to the bone surface at the distal and proximal ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com