Enclosed mechanical stirring flotation machine

A mechanical stirring and flotation machine technology, applied in flotation, solid separation, etc., can solve problems such as heat loss, temperature rise at the work site, heat waste, etc., to achieve convenient operation, avoid heat loss, and reduce steam emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

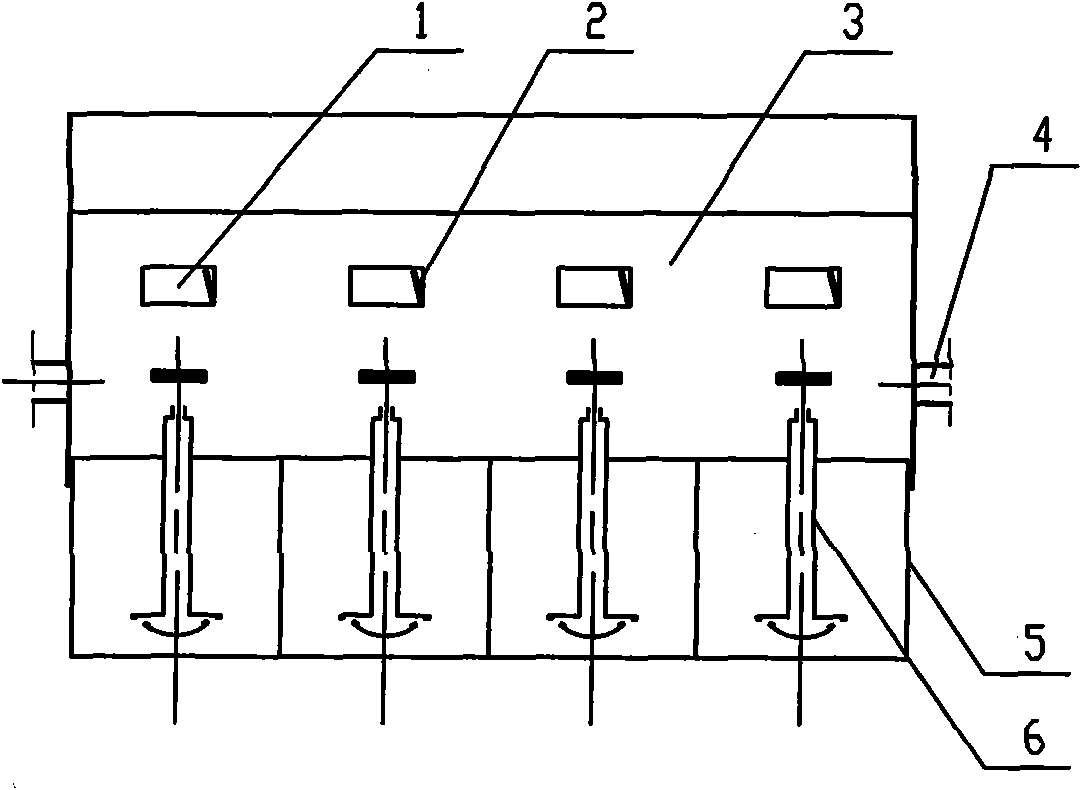

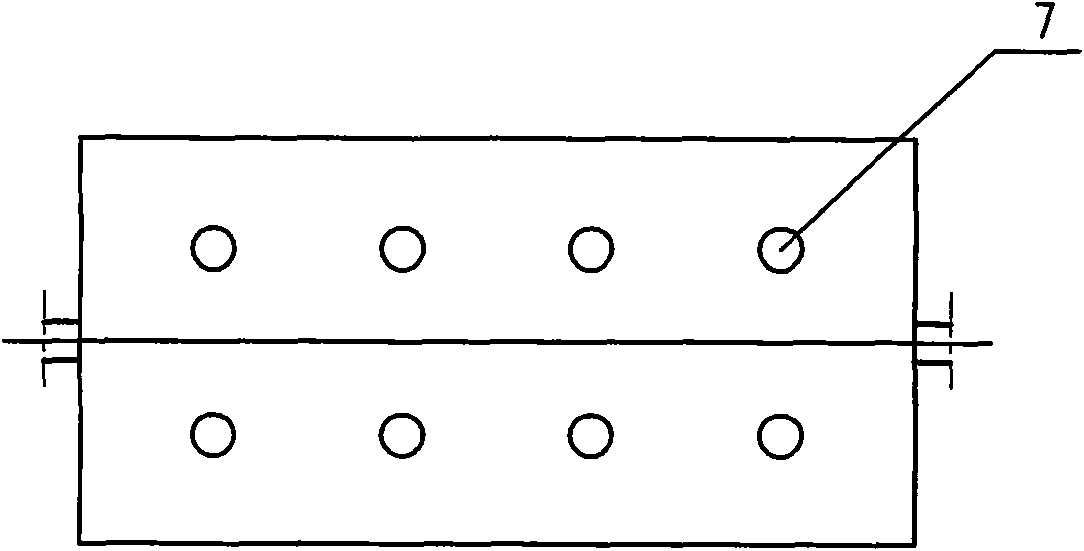

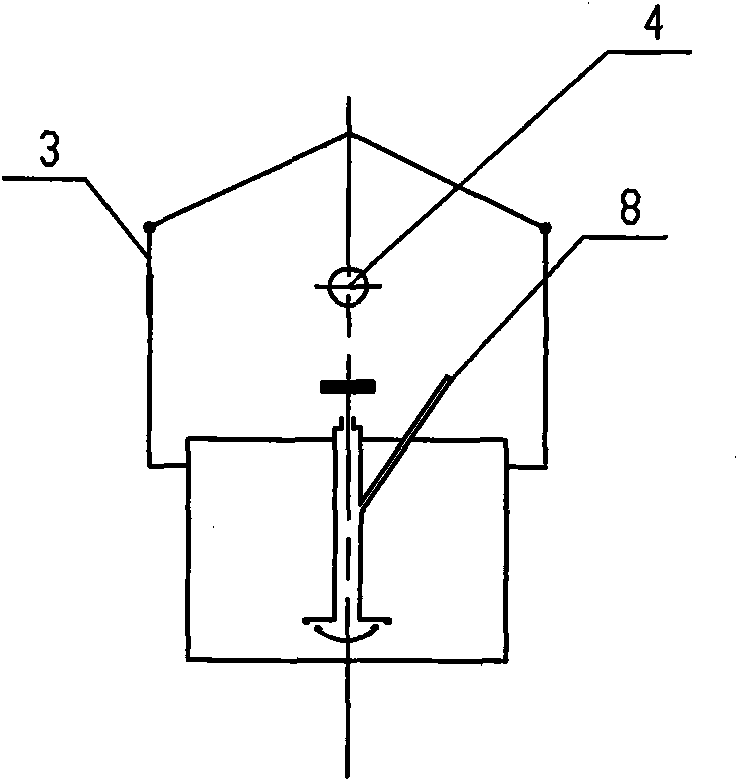

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , 2 , 3, the airtight mechanical agitation type flotation machine of the present invention comprises the machine tank 5 of the flotation machine, the stirring mechanism 6, and the suction pipe 8, and is characterized in that: the described machine tank 5 is provided with a heat preservation cover 3 , the stirring mechanism 6 and the suction pipe 8 are placed in the heat preservation cover 3, and the heat preservation cover 3 is composed of front and rear panels, two side plates, and two top plates, wherein the front and rear panels and the two side plates are welded to each other. Square frame structure, the top plate and the front and rear panels are hinged, and the side panels are overlapped, and the top plate is butted with the top plate to form a roof-shaped structure. The outer surface of the machine tank 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com