Automatic centering device of belted layer of tyre building machine

A tire building machine and automatic centering technology, which is applied to tires, other household appliances, household appliances, etc., can solve problems such as not being in the middle position, being biased to one side, and affecting the quality of formed tires, so as to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

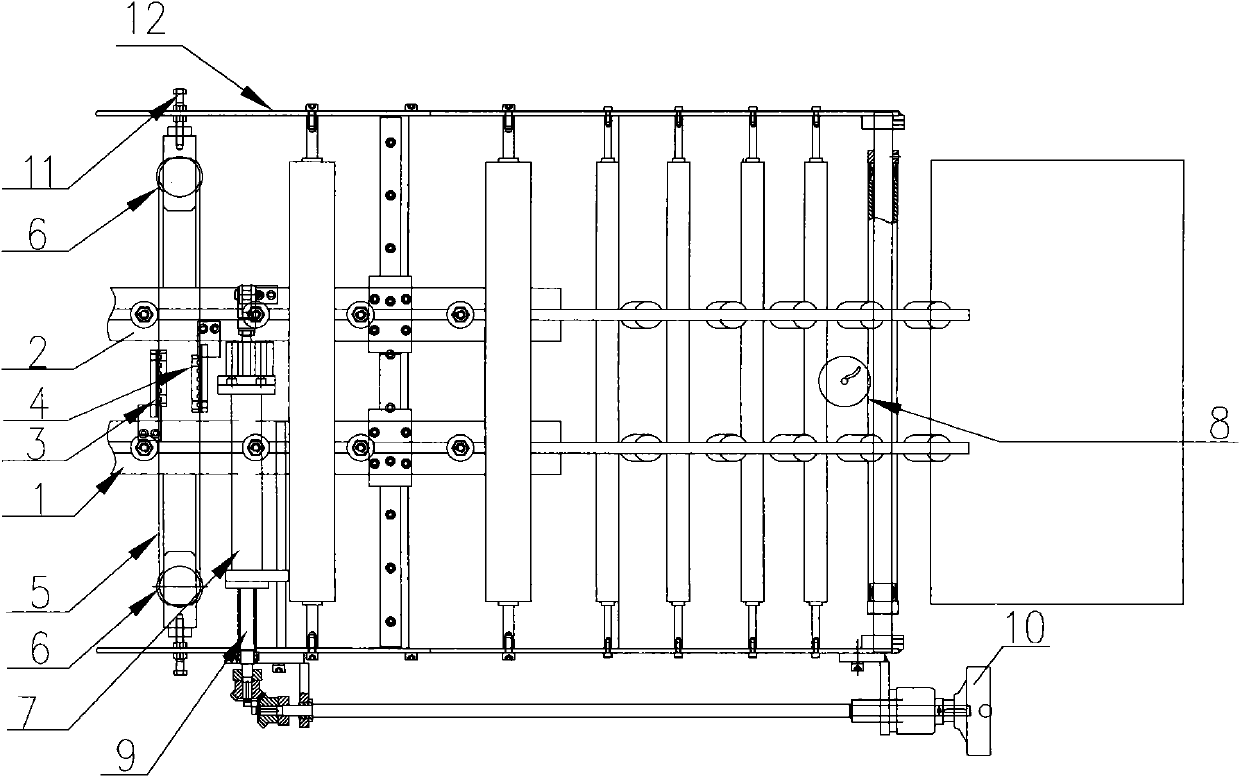

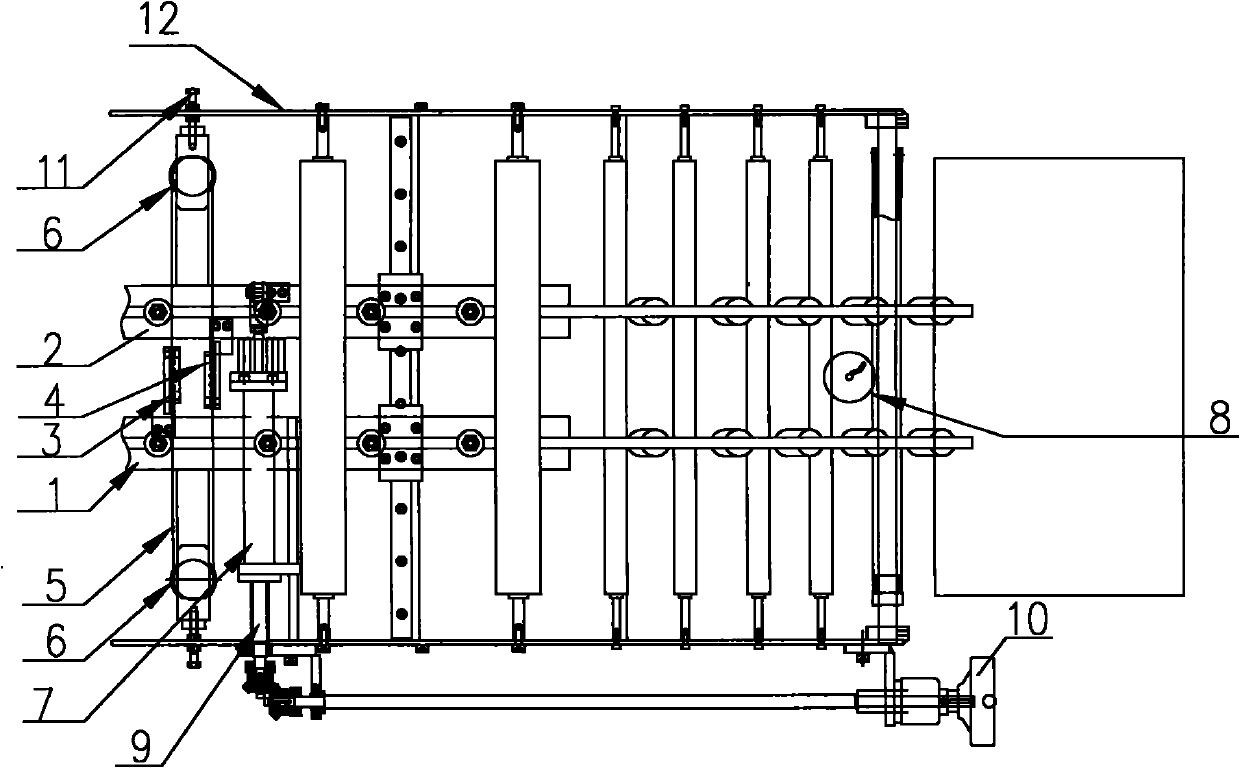

[0009] Embodiment: A belt layer automatic centering device of a tire building machine, which includes left and right guide plates 1 and 2 arranged above the feeding rack 12, the left guide plate 1 is fixedly provided with a left splint 3, and the right guide plate The plate 2 is fixed with a right splint 4, and the left and right splints are respectively driven and connected to both sides of the timing belt 5, and the timing belt 5 is set on the timing belt pulley 6 on both sides of the feed frame 12; a cylinder 7 is provided, and the cylinder The tailstock is fixed on one side of the feed frame 12, the cylinder shaft is connected to the right guide plate 2, and the cylinder drives the synchronous belt 5 to move and at the same time drives the left and right guide plates 2 to move in the opposite direction. Manually adjust the initial distance of the guide plates on both sides; the end of the feeding frame 12 close to the end of the belt drum is provided with a photoelectric se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com